Chemistry, Manufacturing and Controls (CMC) & CDMO Testing Services

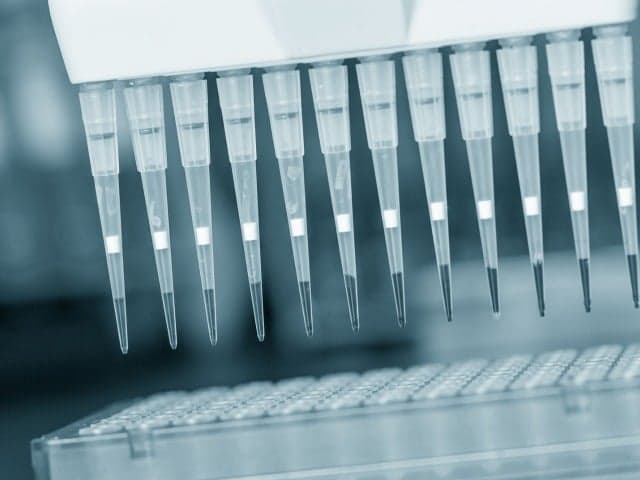

Accelerate your CDMO operations with comprehensive analytical testing solutions that scale with your business. Our integrated biopharma CDMO testing services provide the analytical backbone for successful client programs, offering flexible capacity, regulatory expertise, and advanced capabilities that enable you to deliver exceptional results while expanding your service portfolio and maintaining competitive advantage.

Why Element are global leaders in CMC product development and CDMO testing services

The biopharma CDMO industry faces increasing pressure to deliver complex therapeutic programs on accelerated timelines while maintaining rigorous quality standards. CDMOs must navigate diverse client portfolios spanning small molecules, biologics, and advanced therapies, each requiring specialized analytical capabilities and regulatory compliance across multiple jurisdictions.

Element's comprehensive testing solutions are purpose-built for CDMO operations, providing the analytical backbone that enables contract manufacturers to expand service offerings and deliver exceptional client outcomes. Our specialized expertise transforms analytical challenges into competitive advantages, supporting CDMOs from discovery through commercial manufacturing. We offer the flexibility to scale with business cycles and client demands, from project-based testing to comprehensive long-term partnerships. You optimize analytical spending while maintaining quality, improving your competitive positioning and ability to serve diverse client portfolios effectively.

Our FDA-registered laboratories throughout North America ensure consistent, high-quality testing for your client programs. You gain reliable access to specialized analytical capabilities and standardized protocols, enabling seamless project execution across multiple locations.

Our extensive testing portfolio spans method development through commercial release testing, enabling CDMOs to accept diverse client programs with confidence. State-of-the-art analytical instrumentation and validated methodologies enable you to expand service offerings into complex therapeutic areas. Access cutting-edge capabilities for biologics and ATMPs, cell/gene therapies, and emerging modalities without investing in specialized equipment in-house.

Services

Drug Discovery and Development

Element's CDMO services offer tailored drug discovery and development solutions, helping you reduce costs, accelerate timelines, and advance clinical trials with expert support at every stage.

Microbiological Development and Quality Control Testing Services

Element's lab provides specialist microbiology testing services and quality control for drug products that support all phases of product and process development and help to maintain product integrity.

Premier Molecular Studies and Testing Services

As a premier provider of molecular studies and testing services, Element delivers accurate and reliable results. Our CLIA-certified reference molecular lab is trusted to provide comprehensive molecular characterization of isolates.

Reference Standard Characterization and Management

Element offers pharmaceutical reference standard management, delivering tailored characterization, validation, and storage solutions to meet regulatory requirements and enhance product quality for small molecules, biologics, and biosimilars.

Pharmaceutical Quality Control Testing

Element provides pharmaceutical quality control testing, covering raw materials, APIs, and finished products. Our expert analytical development and validation help meet regulatory requirements and support all phases of product development.

Analytical Method Development & Validation

Element's regulatory and industry experts have a proven track record of successfully developing and validating fit-for-purpose, accurate, and reliable analytical methods based on established CDER/ICH and FDA guidelines and procedures.

Environmental Monitoring Services

Element offers tailored pharmaceutical environmental monitoring services, helping maintain cleanroom control and regulatory compliance while protecting product quality and patient safety.

Biopharmaceuticals & Biologics Analysis Services

Our clients develop safe, efficacious products with confidence thanks to Element’s Biologics and Advanced Therapy Medicinal Products (ATMPS) testing services.

Your Challenges, Our Solutions

Analytical Capacity Bottlenecks

Regulatory Documentation Requirements

Technical Complexity Management

Standards we test to and materials we test

- FDA 21 CFR Parts 210, 211, and 820

- ICH Guidelines (Q1A-Q14, Q3A-Q3D, Q6A-Q6B)

- USP General Chapters (<51>, <61>, <62>, <71>, <85>, <660>, <661>, <671>, <787>, <788>, <797>)

- European Pharmacopoeia (EP) Methods

- Japanese Pharmacopoeia (JP) Methods

- ISO 14644 Cleanroom Standards

- ISO 17025 Laboratory Accreditation

- GMP/GLP Compliance Requirements

Small Molecule Pharmaceuticals:

- Active Pharmaceutical Ingredients (APIs)

- Finished Drug Products (tablets, capsules, injectables)

- Raw Materials and Excipients

- Reference Standards and Impurities

Biologics and Biosimilars:

- Monoclonal Antibodies and Protein Therapeutics

- Vaccines

- Peptide and Protein APIs

- Complex Generics

Advanced Therapy Medicinal Products (ATMPs):

- Cell Therapies and Cellular Products

- Gene Therapies and Viral Vectors

- Tissue Engineered Products

- Combination Products

Packaging and Container Systems:

- Primary Packaging Materials

- Container Closure Systems

- Medical Device Components

- Single-Use Systems

Why Choose Element