Wind Turbine Testing Services

Maximize your wind turbine performance and reliability with comprehensive testing solutions spanning R&D to maintenance. Our expert partnership ensures turbine integrity, optimizes power output, and maximizes uptime while extending operational life. Designed for today's larger, more powerful installationsour end-to-end testing services toensure correct installation and consistent, reliable renewable energy generation.

What are Wind Turbine Testing Services at Element?

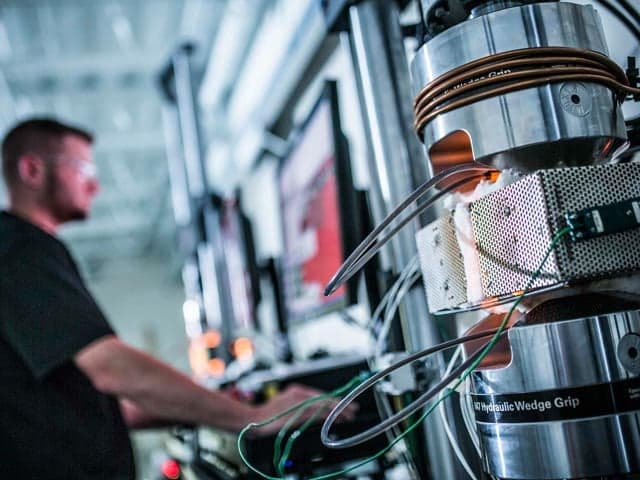

The increasing power output from today’s wind turbines, enabled by taller towers and longer rotor blades, put materials and systems to even stronger tests. Wind turbine testing involves comprehensive evaluation of components, materials, and systems to ensure reliability and performance under demanding operational conditions. At Element, we provide complete testing services spanning materials characterization, structural mechanics, environmental simulation, and field testing for wind turbines, supporting you from development through maintenance.

What Can Element Offer You For Wind Turbine Testing Services?

Key tests offered

Key tests offered

Element offers materials expertise, testing, inspection, and calibration services supporting Wind Turbine OEMs and the Wind industry supply chain from early R&D and production to maintenance and failure investigations.

Windmill materials testing & characterization

- Mechanical testing of metals, composites, and polymers

- Failure Analysis of metals and non-metals

- Concrete and anchor testing

Windmill components testing

- Structural Mechanics Testing

- Digital Engineering (Engineering Critical Assessment, Finite Element Analysis, computational fluid dynamics, discrete element modeling)

- Product Qualification Testing (Accelerated Ageing, UV-weathering, Environmental Stress Screening, Climatic tests, lightning strike, etc)

- Electromagnetic Compatibility (EMC) and electrical safety of radio products and electrical devices

Field services for wind turbine testing

- Laser tracking for precision measuring of blades and large structural components and onsite large area verification of installations

- Fire and life safety programs

- Environmental impact assessments (acoustic/noise testing)

Wind energy maintenance services

- Calibration of tools and measuring devices

- Oil and Lubricants: Quality control and Condition monitoring

Components and materials we test

Components and materials we test

We test every critical component of your wind turbine system, from onshore fundaments and anchors, to offshore monopile and transition piece materials and coatings, to tower materials and fasteners, transmissions and lubricants, as well as blades.

Our comprehensive testing capabilities cover metals, composites, polymers, coatings, and complete assemblies. We understand the unique challenges of large-scale components and provide specialized testing solutions for each element of your wind energy system.

Methods and solutions offered

Methods and solutions offered

Our advanced testing methods combine traditional approaches with cutting-edge digital solutions. We offer:

- Digital Engineering with FEA,CFD analysis, and discrete element modeling

- Laser tracking for precise measurements

- Environmental stress screening

- Accelerated aging simulations

- Failure analysis and investigation

- Quality control monitoring

- Asset integrity management

- Weld procedure qualification

Which labs we offer this service at

Which labs we offer this service at

Our team operates from energy hubs across the world, providing global access to our expert capabilities. Find out where your nearest energy hub is on our Locations Page.

Components and materials we test

Metals and Alloys:

- Tower materials

- Fastener materials

- Monopile materials

- Transition piece materials

Composites and Polymers:

- Blade materials

- Structural components

- Protective coatings

System Components:

- Complete blade assemblies

- Transmission systems

- Foundation structures

- Anchoring systems

- Lubricants and oils

- Radio products and electrical devices

- Blades and large structural components

- Tools and measuring devices (for calibration)

- Onshore fundaments and anchors

- Offshore monopile and transition piece materials and coatings

- Tower materials and fasteners

- Transmissions and lubricants

- Blades

Your Challenges, Our Solutions

Increasing turbine size and power

Harsh environmental conditions

Critical mechanical strength requirements

Maintenance and downtime concerns

Why Choose Element

Global testing network

Complete lifecycle support

Advanced digital solutions

Comprehensive testing integration

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Calibration Services

Optimize accuracy and compliance with Element’s calibration services in Europe, and Asia. Global expertise, local service—electrical, force, dimensional & more.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Product Qualification Testing (PQT) Services

Element’s product qualification testing verifies safety, compliance, and performance, helping businesses reduce risk, accelerate market entry, and meet global standards with expert guidance and accredited testing services.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Weld Testing Methods

Element provides advanced weld testing services, including non-destructive and destructive methods, to verify weld integrity, meet industry standards, and prevent failures in critical applications.

Dimensional Inspection and Metrology

Element's metrology and dimensional inspection services help you shorten production cycles, ensure accuracy, and improve quality control of your components.