Advanced Modeling and Simulation Services

Reduce development costs and accelerate time-to-market with Element's Advanced Modeling and Simulation Services. Our CFD, FEA, and DEM simulations optimize designs, ensure compliance, and solve complex engineering challenges before physical prototyping. With industry-specific expertise and ongoing performance monitoring, we deliver precise, cost-effective, and regulatory-ready solutions for your engineering needs.

What is Advanced Modeling and Simulation Testing at Element

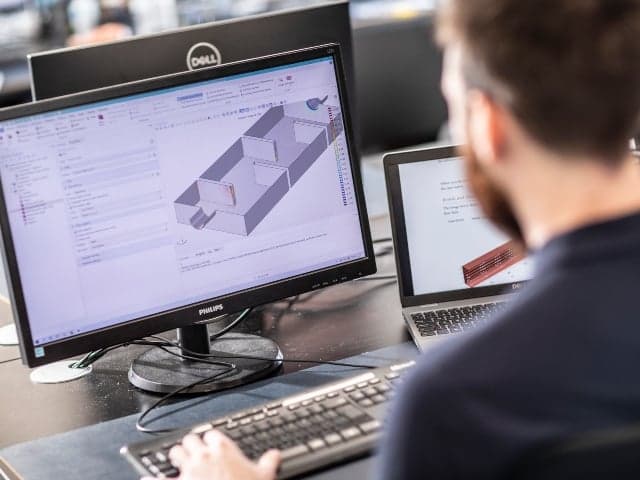

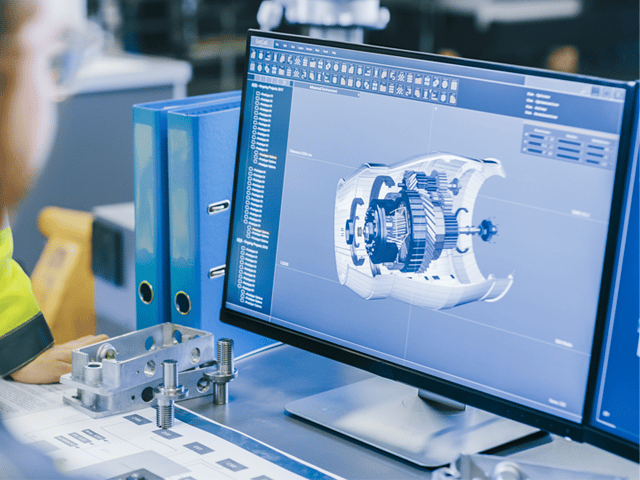

Advanced Modeling and Simulation Services at Element use mathematical models and computer simulations to predict and analyze system behavior under different conditions – without physical experiments. We apply sophisticated methods including Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), Discrete Element Method (DEM), and Electromagnetic Simulation to deliver precise, compliance-focused solutions.

What can Element offer you for Advanced Modeling and Simulation Testing?

Methods and solutions offered

Methods and solutions offered

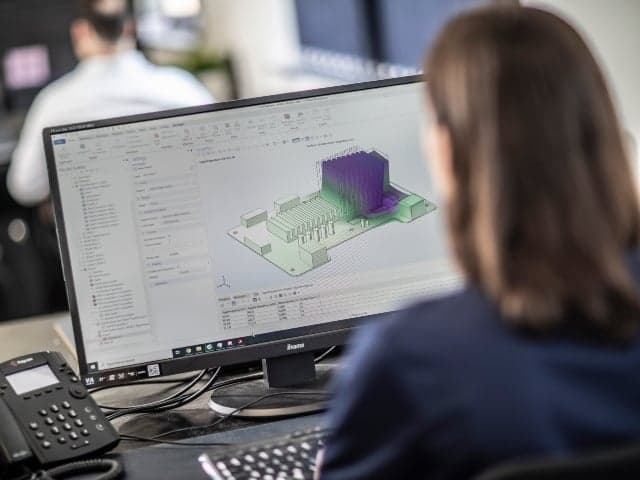

Element's comprehensive simulation portfolio includes CFD analysis for aerodynamics and fluid flow, FEA techniques for structural analysis, DEM solutions for material handling, and electromagnetic feasibility studies. We provide conceptual modeling, feasibility assessment, design optimization, and ongoing performance monitoring to ensure regulatory compliance and product success.

Components and materials we test

Components and materials we test

We test and simulate complex systems including fluid-fluid interactions, fluid-solid interfaces, granular materials, electromagnetic components, structural elements, and thermal management systems. Our simulations support aerospace, defense and energy industries with precision and compliance assurance.

Cutting-edge equipment we use

Cutting-edge equipment we use

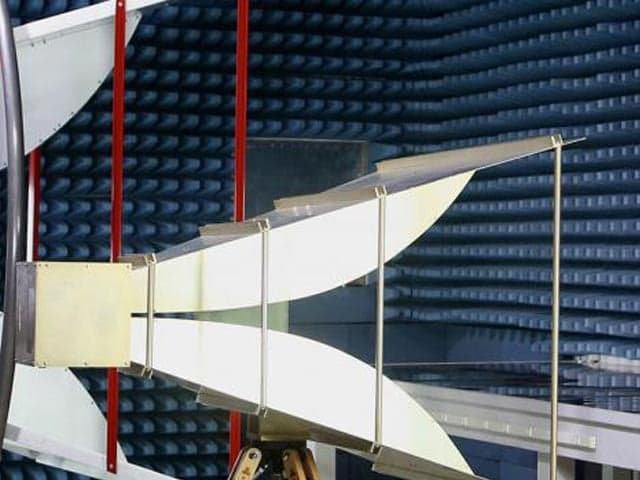

We leverage state-of-the-art simulation platforms and high-performance computing environments to deliver accurate and scalable simulations. Our advanced tools support electromagnetic compatibility testing, structural validation, and thermal performance assessments for a wide range of industries.

Which labs offer this service

Which labs offer this service

Our services are provided worldwide, with key digital engineering hubs located in Bristol, Derby, and Houston. Find out where your nearest digital engineering hub is on our Locations Page.

Ongoing support we provide

Ongoing support we provide

We provide continuous performance monitoring, optimization algorithms, and real-time data analysis to ensure systems maintain peak efficiency. This proactive approach identifies potential issues before they impact operations, helping businesses optimize maintenance schedules, and extend equipment lifespan.

Materials we test

- Fluid systems and flow components

- Structural elements under stress

- Electromagnetic components

- Granular material handling systems

- Thermal management systems

- High-pressure environment components

- Aerospace and defense components

- Transportation systems

- Electronics cooling systems

Your Challenges, Our Solutions

High Development Costs

Time Crunches

Compliance Risk Management

Design Optimization Complexities

Element Experts at your service

Why Choose Element

Global Expert Network

Integrated Simulation Approach

End-to-End Support

Industry-Specific Experience

Frequently asked questions

How does multiphysics simulation benefit product development?

It integrates multiple physical models for comprehensive understanding of product behavior, enabling innovative and robust development.

What role do optimization algorithms play?

They enhance simulations by refining system parameters for peak performance and efficiency.

Can simulation services extend the lifespan of equipment?

Yes, by predicting wear patterns and optimizing maintenance schedules to reduce downtime.

What kind of maintenance optimization can you provide?

We offer real-time data analysis and optimization algorithms for continuous system monitoring. We provide immediate insights and adjustments to maintain peak efficiency.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Applied Engineering Services

Element's Applied Engineering Services can solve your complex engineering challenges, boosting efficiency and innovation.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Discrete Element Method (DEM) Services

Model particle interactions, optimize processes, and improve equipment performance with our Discrete Element Method (DEM) services. Maximize efficiency today.

Electromagnetic Simulation and Modeling Services

Ensure compliance and optimize designs with Element's electromagnetic simulation services. Solve RF, SAR, and thermal challenges with expert modeling.

Engineering Design Services

Enhance your design process with our Engineering Design Services. Our simulation-driven approach and advanced CAD techniques ensure optimal design solutions, reducing your time to market and enhancing product quality.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Software Development for Engineering Services

Discover how Element's custom software development for engineering drives innovation, cuts costs, and streamlines system integrations. From agile prototyping to digital twin technology, our tailored solutions support global customers, enhance performance, and improve reliability—helping you stay ahead in a competitive landscape.

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Prototype Design and Development Services

Discover comprehensive solutions in prototype design and development services for fluid systems, from concept to testing; ensuring rapid timelines, stringent standards compliance, and exceptional reliability.