Flammability Testing for Aircraft Interiors – FAA Approved

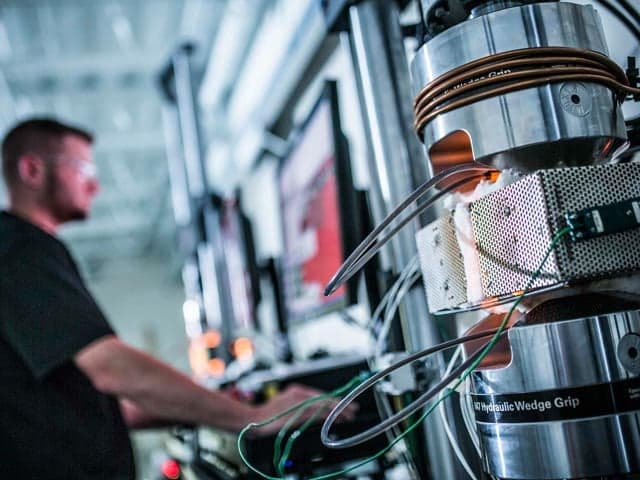

Ensure your aircraft interior materials meet mandatory FAA safety requirements with Element's comprehensive flammability testing services. We evaluate all critical characteristics including burn rates, ignition resistance, heat release, and smoke density, and provide direct access to FAA designated engineering representatives. As the largest independent aerospace testing provider in the world, we streamline your certification process by managing all testing and compliance requirements.

What is flammability testing for aircraft interiors at Element?

Element's flammability laboratories specialize in testing aircraft interior materials against key global safety standards, with FAA and Nadcap approval, plus UKAS / ISO / IEC 17025 accreditation. Our comprehensive flammability testing measures how long it takes airplane cabin materials and products to burn, how easily they ignite, and how they react when burned. This provides the critical data you need for aerospace qualification programs and full regulatory compliance.

What can Element offer you for flammability testing of aircraft interiors?

Key tests offered

Key tests offered

Element's aircraft flammability testing labs can assist with characterizing burning properties, smoke analysis, and other flammability tests, including:

- FAA flammability

- OSU heat release rate

- NBS smoke density

- Smoke toxicity testing

- Vertical ignition (vertical burn)

- Flame Penetration (45-degree burn)

- Horizontal ignition

Components and materials we test

Components and materials we test

Element tests a complete range of aircraft interior materials to the most exacting standards, including cabin components, textiles, upholstery, and plastics – to name but a few. Our testing includes an evaluation of critical flame characteristics to make sure materials meet all strict aerospace safety requirements and qualification standards.

Which labs offer this service

Which labs offer this service

Our global network of 29 Nadcap accredited and aerospace supplier-approved aerospace materials testing laboratories together with our highly experienced team of Aerospace Materials and Flammability Testing Experts, provide a comprehensive range of aircraft flammability testing services. Our Los Angeles lab is a center of excellence for FAA-approved flammability testing.

Combine your testing

Combine your testing

With Element, you can combine your aircraft interiors testing with other accredited programs such as RTCA DO-160. This critical standard ensures that avionics systems function properly in the various environmental conditions they may encounter on an aircraft. By conducting all your testing needs with one supplier, you save time, cost and hassle of managing multiple testing suppliers while ensuring the safety and reliability of your materials.

Standards we test to and materials we test

Airbus

- ABD 0031

- AITM 2.0002, AITM 2.0003, AITM 2.0004, AITM 2.0005, AITM 2.0006, AITM 2.0007, AITM 2.0038, AITM 2.0008, AITM 3.0005

American Society for Testing & Materials

- ASTM D568, ASTM D635, ASTM E662, ASTM D3801, ASTM D4804

Boeing

- BSS 7238, BSS 7239, BSS 7230, BSS 7322

Department of Transportation

- FMVSS 302

Federal Aviation Regulations

- ISO / IEC 17025

Your Challenges, Our Solutions

Complex Compliance Requirements

Technical Knowledge Gaps

Quality Assurance Concerns

Manage Multiple Certifications

Element Experts at your service

Why Choose Element

Global Leadership

Comprehensive Approvals

Quality Accreditation

Industry Experience

Proof points

80+years of aerospace experience

29Nadcap labs

3,000technical staff

8,500engaged experts

Frequently asked questions

What types of flame characteristics do Element test for?

Element's testing evaluates burn time, ignition resistance, and material reactions when burned - all critical safety aspects for aircraft interior materials.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace

Element are the largest global independent provider of aerospace testing services with over 100 years of experience and world-class testing, qualification, calibration, and advisory services.

Fire and Flammability Testing Services

Explore the range of fire & flammability testing services from Element. Ensure compliance with global labs, expert guidance & fast results.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Aerospace Fire Testing

Validate aircraft components with fireproof and fire resistance testing. Identify risks, meet industry standards, and maintain safety with expert aerospace fire testing.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.