Aerospace Materials Testing

Element delivers critical aerospace materials testing services across the complete product lifecycle – from R&D to ongoing in-service support. Our extensive materials testing capabilities mean you can validate performance, achieve regulatory compliance, and maintain the highest safety standards, all while meeting demanding production schedules.

What is Aerospace Materials Testing at Element?

Material failure is simply not an option in a safety-critical industry like aerospace. Aerospace materials testing rigorously examines the properties and behaviour of your aircraft’s materials to ensure they are fit for purpose and can withstand the most extreme conditions during flight.

Through a range of destructive and non-destructive test methods, Element’s highly specialized experts can help you meet your deadlines and quality requirements, delivering quickly but – most importantly – accurately and efficiently.

What can Element offer you for Aerospace Materials Testing?

Components and materials we test

Components and materials we test

Element's comprehensive testing capabilities cover the full spectrum of aerospace materials, from traditional metals and alloys to advanced composites and innovative coatings. We provide detailed material characterization and validation, so you can be sure your components meet stringent aerospace application requirements.

Methods and solutions offered

Methods and solutions offered

- Fatigue testing and fracture mechanics

- Tension and compression testing

- Impact and hardness testing

- Stress rupture and creep testing

- Non-destructive testing (NDT)

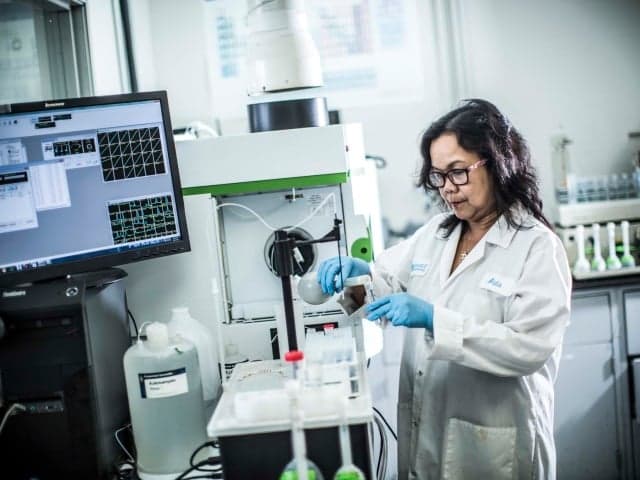

- Metallurgical testing and microscopy

- Chemical analysis

- Failure analysis and investigation

- Expert witness services

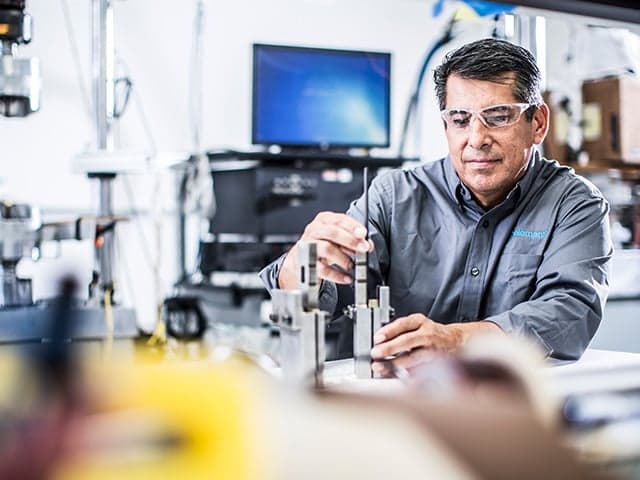

Cutting-edge equipment we use

Cutting-edge equipment we use

Everything we do is designed to help our customers deliver materials, products and services that are always safe, quality, compliant and fit for purpose. Which is why our extensive range of mechanical testing equipment is always made up of the latest and most advanced technologies.

Which labs offer this service

Which labs offer this service

The Element global network includes 35 industry leading, Nadcap-accredited laboratories strategically located in aerospace industry hubs. So wherever you – or your materials – are based in the world, we can provide you with convenient local access to world-class testing capabilities.

End to End support capabilities

End to End support capabilities

From supporting your research and development (R&D), to production support, through in-service support and failure analysis, Element’s aviation experts have the expertise and access to state-of-the-art laboratories required to complete your projects.

Materials we test

Metals and Alloys:

- Nickel alloys

- Titanium alloys

- Aluminum

- Superalloys such as Inconel, Hastelloy, single crystal alloys, Rene

Composites and other Non-Metallics:

- Ceramic Matrix Composites (CMCs)

- Polymer Matrix Composites

- Plastics

- Elastomers

Joining Materials:

- Adhesives

- Fasteners and fastening systems

Your Challenges, Our Solutions

Lack of specific expertise

Time-to-Market Pressure

Production Support Challenges

Meeting Quality Assurance Demands

Why Choose Element

Global Reach, Local Support

Technical Excellence

Comprehensive Capabilities

Industry Leadership

80+years of aerospace experience

35Nadcap labs

3,000dedicated

8,500strong

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

How do you ensure aerospace quality requirements are met?

Our Nadcap-accredited laboratories and experienced aerospace materials testing specialists deliver high-quality data, detailed test reports, and certificates for your materials application and compliance programs.

What aerospace testing support do you provide during production?

We deliver both high-volume routine testing and custom programs, with the capacity, capabilities, and credentials to meet challenging deadlines and strict quality requirements of aerospace production.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Mechanical Testing

View our range of aerospace mechanical testing services for both metals and non-metals - designed to help ensure that your materials are suitable for aviation use where failure is not an option.

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Flammability Testing for Aircraft Interiors – FAA Approved

Ensure your aircraft interior materials meet mandatory FAA safety requirements with Element's comprehensive flammability testing services. Learn More.

Aircraft Structural Testing

Learn how our Aircraft Structural Testing services can help enhance your aerospace structure safety, durability and provide a competitive market edge. From defect detection to design support, reach market faster and more safely.

Aerospace Fastener Testing Services

Element's comprehensive testing program ensures that your materials and processes will meet the high performance expectations of the aerospace industry.

Additive Manufacturing Testing

Element is at the forefront of additive manufacturing technology, providing critical testing services to clients in aerospace, transportation, medical devices, and beyond.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Hardness Testing Services

Element offers comprehensive hardness testing services, including micro, macro, and hot hardness testing. With lab and on-site options, we help assess material durability for engineering, manufacturing, and compliance needs.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

- Aerospace Mechanical Testing

- Aerospace Composite Testing

- Flammability Testing for Aircraft Interiors – FAA Approved

- Aircraft Structural Testing

- Aerospace Fastener Testing Services

- Additive Manufacturing Testing

- Metallurgical Testing Services

- Non-Destructive Testing (NDT) and Inspection Services

- Chemical Analysis Services

- Paint and Coating Testing Services

- Stress Rupture and Creep Testing

- Charpy Impact Testing Services

- Fatigue Testing Services

- Hardness Testing Services

- Tensile Testing