Non-Metallic Materials Testing

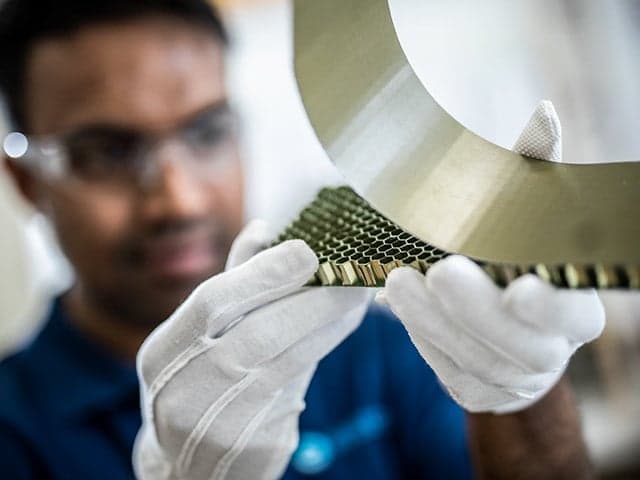

At Element we provide comprehensive testing to validate the integrity and lifespan of your non-metallic materials. Our research-active experts analyze composites, polymers, elastomers, textiles and more to help you ensure compliance, optimize selection, and develop stronger products. With global expertise and local service, we'll help you understand your materials' performance limits while meeting all regulatory requirements.

What are Non-metallic Materials Testing at Element?

Non-metallic materials testing evaluates the physical properties and performance characteristics of composites, polymers, elastomers and other non-metal materials. At Element, we provide comprehensive testing across strength, flexibility, fatigue and other critical parameters to determine material integrity and useful lifespan.

What Can Element Offer You for Non-metallic Materials Testing?

Key Tests Offered

Key Tests Offered

We test non-metallic materials for the kind of physical properties metals are usually tested for, including strength, flexibility, and fatigue. We use multiple testing methods to accommodate a wide variety of product types and requirements, including:

- Air / Water Permeability

- Chemical Resistance

- Flexural Testing

- Heat Deflection Temperature

- Odor Evaluation

- Peel / Adhesion Testing

- Rheological Analysis

- Scratch Testing

- Surface Properties Testing

Components And Products We Test

Components And Products We Test

We test a comprehensive range of non-metallic materials including adhesives, foam, leather, paints, coatings, paper products, rubber, elastomers, textiles, and vinyl products. Our expertise spans both basic materials and complex composites, ensuring you get the right testing for your specific needs.

Methods And Solutions Offered

Methods And Solutions Offered

Our engaged experts research, publish and work on the latest materials and techniques, providing customized test programs tailored to your needs. We offer material selection support, testing to industry standards or your quality system, and optimization guidance to help you understand the limits of your material and determine its integrity and useful lifespan.

Educational Partnership

Educational Partnership

Access our extensive knowledge base through blog posts, articles, white papers, and webinars. Our experts provide training support and ongoing consultation to help you better understand your materials and testing requirements.

Materials we test

Our Materials Testing experts cover a broad scope of materials, including, but not limited to:

- Adhesives

- Foam

- Leather

- Paints and Coatings

- Paper Products

- Rubber and Elastomers

- Textiles

- Vinyl and Rolled Goods

- Organic and non-organic compounds

Your Challenges, Our Solutions

Material Performance Uncertainty

Complex Compliance Requirements

Material Selection Decisions

Quality Control Confidence

Why Choose Element

Research-Driven Expertise

Customized Solutions

Comprehensive Capabilities

Broad scope of materials

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

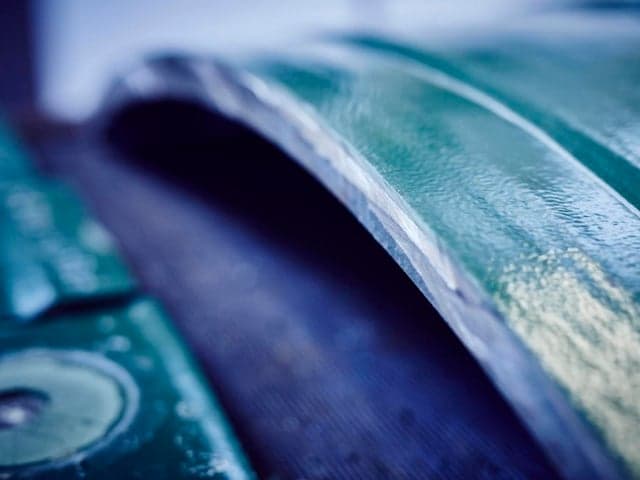

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Impact Testing of Polymers and Composites

Element's testing of polymers can enhance your product's durability, performance, reliability and safety across a range of industries.