Thermal Analysis Services

Gain critical insights into your material's behavior with precise thermal analysis that reveals performance across temperatures and loads. Element's comprehensive testing methods identify key material characteristics, helping you prevent failures and optimize material selection for your specific applications.

What is Thermal Analysis at Element?

Thermal analysis measures physical, mechanical, chemical, and thermodynamic changes in materials under varying temperatures and loads. At Element, our methods pinpoint critical temperature thresholds and material transitions, ensuring optimal performance and longevity. We combine heat and mechanical force measurements to track changes in material structure, helping determine if materials are appropriate for their intended application or use. Our expertise extends beyond standard testing to include in-depth molecular analysis of crystalline and amorphous polymers.

What Can Element Offer You For Thermal Analysis Services?

Key tests offered

Key tests offered

Access our comprehensive suite of thermal analysis methods to fully characterize your materials. Element offers highly reliable thermal analysis services, including:

- Thermogravimetric analysis (TGA)

- Differential scanning calorimetry (DSC)

- Dynamic Mechanical Analysis (DMA)

- Thermomechanical Analysis (TMA)

- Heat Deflection Temperature

- Linear Thermal Expansion

Materials we test

Materials we test

Our laboratories specialize in analyzing non-metallic materials including plastics, rubbers, and composite materials. We provide detailed characterization of both crystalline and amorphous polymers, helping you understand material behavior across various temperature ranges and loads. Our expertise extends to:

- Advanced composite materials

- Thermoplastics and thermosets

- Elastomers and rubber compounds

- Novel polymer formulations

Methods and solutions offered

Methods and solutions offered

Thermal analysis uses a combination of heat and mechanical force to track changes in material structure and helps determine if materials are appropriate for the intended application or use. By using a model of temperature over time, these methods provide accurate data about glass transition temperature (Tg), coefficient of linear thermal expansion (CTE), specific heat, melting temperature, phase transitions, and more. Our thermal analysis services deliver precise measurements of:

-

Glass transition temperature (Tg)

-

Coefficient of linear thermal expansion (CTE)

-

Specific heat properties

-

Melting temperature characteristics

-

Phase transitions

-

Complex moduli

-

Viscoelastic behavior

-

Material mass changes

-

Dimensional stability

Expert polymer analysis

Our polymer specialists provide comprehensive analysis and interpretation of thermal testing results, helping you:

-

Understand complex material behavior

-

Identify unknown materials

-

Support research and development

-

Optimize material selection

-

Predict performance characteristics

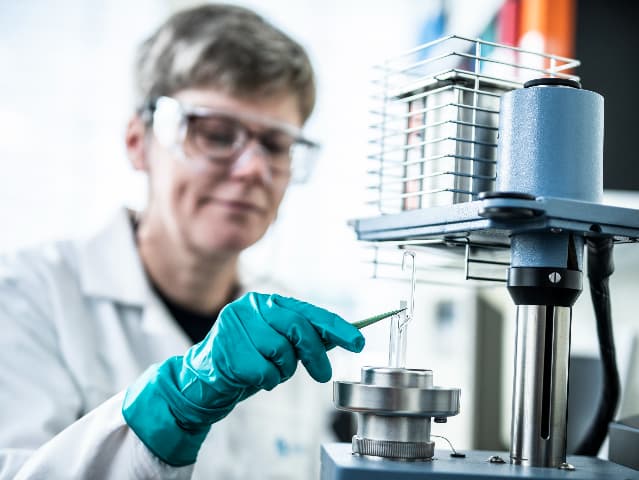

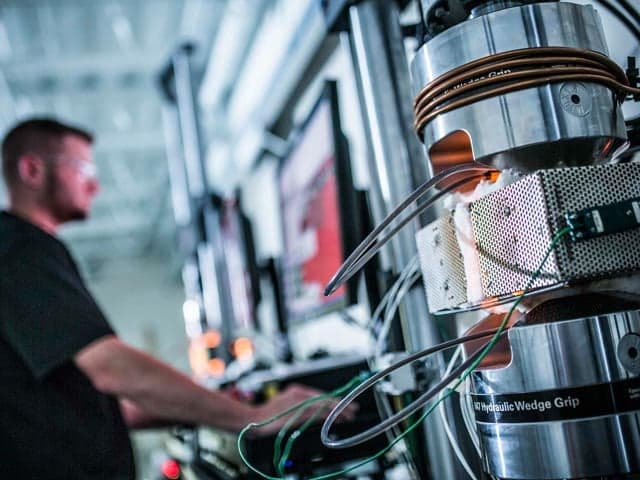

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories utilize advanced thermal analysis instruments including:

- TGA systems for precise mass measurement

- DSC analyzers for thermal property assessment

- DMA equipment for mechanical property testing

- TMA systems with quartz probe technology

- Temperature-controlled testing chambers

- Precision measurement systems

Materials we test

Non-metallic materials

- Plastics

- Rubbers

- Polymers

Polymer types

- Crystalline polymers

- Amorphous polymers

- Thermoplastics

- Thermosets

Composite materials

- Advanced composites

- Novel composites

- Research materials

Your Challenges, Our Solutions

Uncertainty in Material Behavior

Difficulty in Characterizing Non-Metallic Materials

Risk of Material Failures

Need for Fast and Accurate Testing

Why Choose Element

Polymer expertise

Comprehensive methods

Accurate results

Global reach

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Thermogravimetric Analysis (TGA) Services

Element's thermogravimetric analysis (TGA) services help identify phase transitions, degradation reactions, and material composition, providing critical insights for research, development, and compliance across industries.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.

Differential Scanning Calorimetry (DSC) Analysis Services

Element's Differential Scanning Calorimetry (DSC) analysis measures material properties, helping you optimize designs and ensure performance with accurate thermal data for informed decision-making in product development.

Dynamic Mechanical Analysis – DMA Analysis

Element offers DMA testing to analyse thermal and mechanical properties of non-metallic materials. We provide insights into stiffness, damping, and glass transition to enhance material performance.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.