Chemical Processing Services

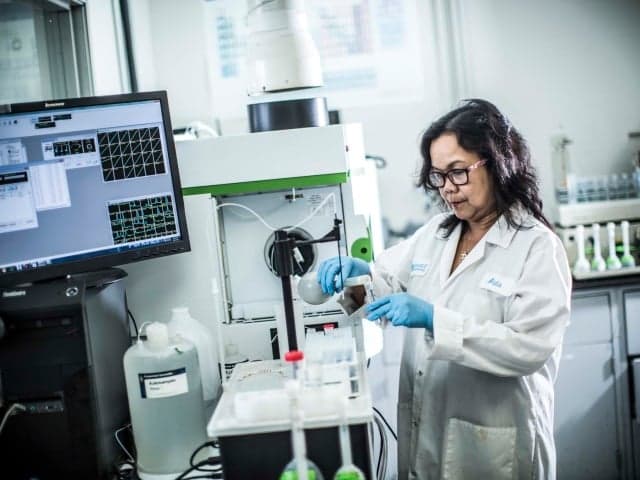

Optimize your materials’ performance with precision chemical processing services that meet the highest industry standards. From pre-testing preparation to post-production treatment, our expert-led methods, including etching, passivation, and cleaning, ensure reliable, high-quality results. Benefit from advanced staff training, precise control of processing solutions, and industry-recognized expertise for seamless testing and performance optimization.

What are Chemical Processing Services at Element?

Chemical Processing involves specialized treatment of materials to prepare them for testing or enhance their performance characteristics. At Element, we provide comprehensive chemical processing methods, including etching, cleaning, and passivation services, all designed to meet specific engineering requirements critical to your product’s function and performance. Our methods ensure precise surface preparation, meeting the highest industry standards and minimizing variations.

What Can Element Offer You For Chemical Processing Services?

Key tests offered

Key tests offered

We provide specialized chemical processing services including pre-penetrant etching, macro etching for grain size measurements and defect solutions, passivation for corrosion resistance, and alkaline cleaning for non-ferrous materials. Our processing capabilities support both testing preparation and post-production treatment requirements, delivering optimal material performance across applications.

Materials we test

Materials we test

Our expert team processes titanium, aluminum, magnesium, stainless steels, and nickel-based alloys. Each material receives specialized treatment tailored to its unique properties and your specific requirements. Our expertise extends to both standard and super alloys, with particular focus on materials requiring precise surface preparation for testing or performance enhancement.

Materials specialties:

- Titanium and super alloys for aerospace

- Stainless steels for corrosion resistance

- Nickel-based alloys for high-performance applications

- Non-ferrous materials requiring specialized treatment

Methods and solutions offered

Methods and solutions offered

Our chemical processing methods are controlled and monitored by trained staff to minimize variations and errors. We offer solutions for specific material requirements and engineering specifications, with each process carefully designed to meet the highest industry quality standards. Our methods focus on delivering consistent, reliable results that are critical to your product's function and performance.

Our chemical processing services include etching and cleaning of various products and materials. Key applications include:

- Pre-penetrant etching of titanium, aluminum, magnesium, stainless steels, and nickel alloys for non-destructive testing.

- Macro etching of super nickel and titanium alloys for grain size analysis and defect identification.

- Passivation of stainless steels to improve corrosion resistance.

- Alkaline cleaning for non-ferrous materials.

Advanced quality control

Advanced quality control

Our staff receives specialized chemical processing training, enabling precise control of processing solutions and quality standards that meet industry requirements. This advanced training ensures consistent results across all processing methods, from etching to passivation, maintaining the highest level of quality in the industry.

Standards we test to and materials we test

American Society for Testing & Methods

- ASTM A262, ASTM A380, ASTM A561, ASTM A604, ASTM A763, ASTM A967, ASTM D3759, ASTM E345, ASTM E381, ASTM E45, ASTM E407, ASTM E562, ASTM E646

General Motors

- GM4345M

Military Standards

- MIL-S-5002, MIL-STD-753

Society of Automotive Engineers

- AMS 2380, AMS 2643, AMS 2700, AMS-QQ-P-35, SAE J123, SAE J1061

- Titanium and titanium alloys

- Aluminum and aluminum alloys

- Stainless steels

- Nickel-based alloys

- Magnesium alloys

- Super nickel alloys

- Non-ferrous materials

Your Challenges, Our Solutions

Inconsistent Material Preparation

Challenging Industry Compliance

Material performance optimization

Surface Treatment Deficiencies

Why Choose Element

Industry-leading expertise

Comprehensive processing solutions

Quality assurance

Technology leadership

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Chemical Etching Services

Element’s chemical etching services detect hidden defects, refine material surfaces, and prepare samples for advanced testing. Trusted for precise, non-destructive analysis - save time and cost by uncovering imperfections before NDT or mechanical testing.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Passivation Services

Expert passivation testing & metal passivation services for corrosion prevention. Chemical processing solutions for aerospace, defense & automotive.