Aircraft Fuel System Testing

Your aircraft aerostructure and engine fuel systems face increasingly complex regulations and design challenges. Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement a tailored test program to precisely simulate real-world conditions. Our advanced capabilities give you complete confidence in your products while ensuring regulatory compliance.

What is Aircraft Fuel System Testing at Element?

Aircraft Fuel System Testing ensures that your fuel system can function properly under a variety of extreme conditions. Because of the complicated nature of fuel systems, testing must be performed in-situ with comprehensive test protocols to simulate real-world operational conditions. At Element, we test individual components through to complete systems, reproducing every flight phase condition from take-off and cruise to descent and landing while monitoring temperature, pressure, and performance to ensure your products meet the highest safety and reliability standards. Using innovative techniques, our laboratories can reproduce and control any condition experienced in normal operation, including fuel icing and hot fuel testing, design for life endurance, and can monitor and report on any unusual effects.

What can Element offer you for Aircraft Fuel System Testing?

Key tests offered

Key tests offered

We can duplicate “iron horse rigs” that simulate the exact installation configurations. Hot or cold fuel can be provided, duplicating engine operational parameters. Our testing covers fuel icing to ARP1401 standards, fuel contamination monitoring, hot fuel testing for extreme conditions, and custom testing programs designed to meet your specific requirements.

Specific capabilities include:

- Fuel contamination

- Hot fuel testing

- Simulated operation

- Custom fuel system testing

- System Performance Requirements

- Tubing and Hose Testing

- Quick Connector Testing

- Fuel Recirculation and Exposure

Components and materials we test

Components and materials we test

We test complete fuel systems and individual components, including main fuel pumps, metering units, heat exchangers, tanks, filters, and tubing. Our comprehensive testing capabilities allow us to test at the component or aerostructure or engine system level, simulating multiple flight cycles to validate long-term safety and performance of your entire fuel system or specific components.

Cutting-edge equipment we use

Cutting-edge equipment we use

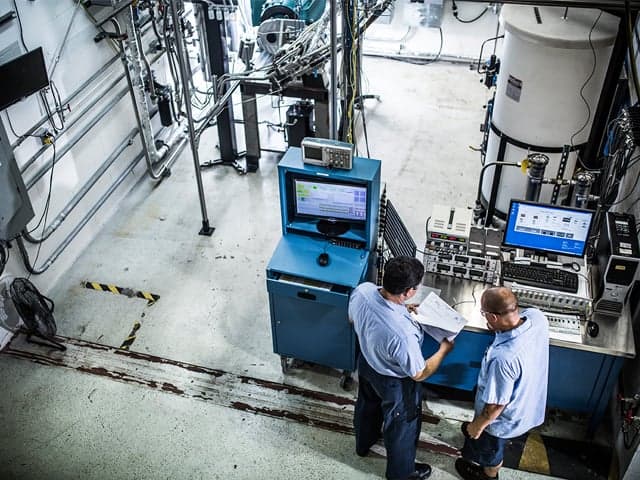

Our facilities feature 400HP drives and gearboxes to interface with the main pumps of your engine fuel system. Hot oil and cold fuel with ice can be supplied to simulate real life operational environment.

We have multiple fuel systems with the largest being 4000 gallons. Fuel can be conditioned from temperatures from -65°F to 100°F.

We employ our own tailored and modified Karl-Fischer titration processes for accurate and controlled water content measurement.

Which labs offer this service

Which labs offer this service

For over 30 years, Element Jupiter has been the go-to lab for challenging engineering projects for key Prime partners.

Plus, our 3,000-strong team operates from aerospace hubs across the world, providing global access to our expert capabilities. Find out where your aerospace hub is on our Locations Page.

Standards we test to and products we test

- Individual fuel system components

- Complete fuel systems

- Main fuel pumps

- Fuel metering units

- Heat exchangers

- Fuel tanks

- Filters

- Tubing

- Complete aerostructure and engine fuel system assemblies

- Quick connectors

- Valves

- Actuators

Your Challenges, Our Solutions

Complying With Rigorous Regulations

Complex System Integration

Extreme Operating Conditions

Multiple Flight Phase Validation

Why Choose Element

Industry Leadership

Flexibility & Scale

Proven Track Record of Partnership

Technical Innovation

4,000gallon

400HPdrive

-65°F to 100°Ftemperature

3,000+Aerospace

Frequently asked questions

How do you ensure fuel contamination testing accuracy?

We introduce predetermined contamination media regularly during testing and closely monitor for anomalies, ensuring your system properly manages solid and liquid particulate during operation.

What happens during hot fuel testing?

We safely conduct testing at elevated temperatures to validate your product's performance when fuel degrades and loses viscosity, ensuring safety and operability under extreme conditions.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Aircraft Icing and Rain Test Methods

Element performs icing and rain tests to provide you with valuable data on product performance in extreme environmental conditions, helping you meet aerospace and military standards.

Low Lubricity Aircraft Fuel Testing Services

Low lubricity aircraft fuel testing evaluates fluid performance under extreme conditions, identifying wear risks and optimizing maintenance strategies. Element provides precise, industry-standard testing for enhanced system longevity.

Fuels and Lubricants Testing

Independent fuels and lubricants testing identifies contamination, wear, and compliance risks. Oil analysis and condition monitoring help prevent failures, reduce maintenance costs, and extend equipment life.

Fluid Susceptibility Contamination Testing Services

Fluid susceptibility and contaminations tests can confirm what a product can withstand when faced with specific liquids and chemicals in the real world.