X-Ray Fluorescence (XRF) Testing Services

Get precise material composition data without compromising your samples. Our XRF testing services deliver accurate chemical analysis with rapid turnaround times, supporting both on-site and laboratory testing needs. Ideal for quality control, regulatory compliance, and research, with little to no sample preparation required.

What are X-Ray Fluorescence (XRF) Testing Services at Element?

X-Ray Fluorescence testing is a non-destructive analytical method that determines a material's chemical composition. At Element, we provide XRF analysis using both portable and laboratory-based equipment to identify and quantify elements present in your materials. This versatile technique works for solids, liquids, and powders, providing precise results with minimal sample preparation.

What Can Element Offer You For X-Ray Fluorescence (XRF) Testing Services?

Key tests offered

Key tests offered

We perform both portable and laboratory XRF analysis, offering elemental composition testing, trace element detection, and quantitative analysis of major constituents. Our testing provides detailed chemical composition reports through secondary x-ray photon analysis, identifying specific energy signatures of elements present in your materials. The process delivers highly accurate elemental identification and quantification, with specialized crystal selection for optimal element detection. Our comprehensive analysis covers the full spectrum of elemental composition requirements.

Materials we test

Materials we test

Our XRF testing analyzes metals, alloys, powders, liquids, and solid samples with minimal preparation requirements. We provide comprehensive elemental analysis for both trace elements and major constituents, delivering accurate composition data for your quality control needs. The non-destructive nature of our testing preserves your materials while providing precise results for a wide range of applications across manufacturing, research, and quality control sectors. Our expertise covers materials of all complexities, from simple metal alloys to complex chemical compounds.

Methods and solutions offered

Methods and solutions offered

Choose between portable on-site XRF testing for immediate results or laboratory analysis for more detailed findings. On-site testing uses handheld analyzers that generate instant material composition readouts, while our laboratory testing employs vacuum chamber technology for enhanced accuracy and broader element detection. Each method is optimized for specific testing requirements and material types, providing flexibility for your testing needs. Our vacuum chamber technology enables detection of lighter elements and provides enhanced accuracy for the most demanding applications.

- On-site testing for immediate results

- Laboratory analysis for enhanced accuracy

- Vacuum chamber technology for detailed analysis

- Minimal sample preparation required

- Customized testing approaches for different material types

Portable XRF Testing Services

Testing can be done on-site or in our labs. On-site, a handheld analyzer directs a beam at the material, sending feedback to a portable device that provides immediate results, identifying the types and quantities of elements. Portable XRF is ideal for quick checks of structures or individual items, covering a wide range of metals, including trace elements and major components.

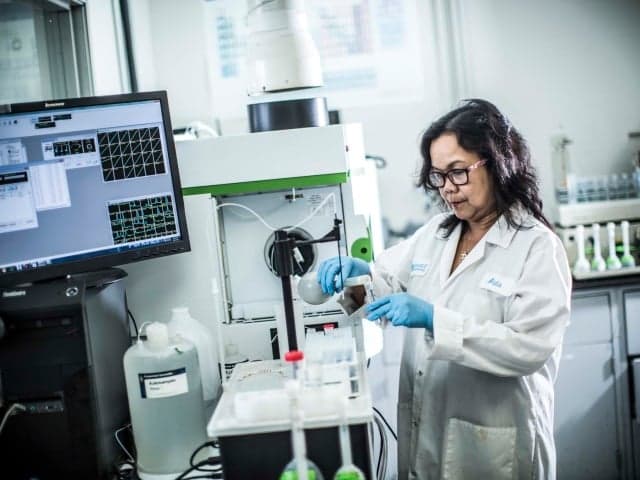

Laboratory XRF Testing Services

Our in-laboratory XRF uses a more advanced analyzer. Samples must meet size requirements, and materials are tested in a vacuum chamber. While this method takes longer than field testing, it offers a broader range of elements and more detailed, accurate results, making it preferred for comprehensive analyses.

Cutting-edge equipment we use

Cutting-edge equipment we use

We utilize advanced XRF analyzers including portable handheld devices for field testing and sophisticated laboratory equipment with vacuum chamber technology. Our instruments employ high-energy primary x-ray beams to analyze materials, with specialized detectors counting emitted photons dispersed by selected crystals to identify and quantify elements present in your samples. The technology enables precise measurement of both major constituents and trace elements, providing comprehensive compositional analysis for quality control and regulatory compliance.

Standards we test to and materials we test

We deliver results on time and on budget – and test to a wide range of standards, including:

- American Society for Nondestructive Testing

- NDE-60.18

- American Society for Testing & Materials

- ASTM B568, ASTM E1085, ASTM E1476, ASTM E1621, ASTM E322, ASTM E539, ASTM E572

Metals and alloys

- Structural metals

- Engineering alloys

- Metal materials

- Trace element analysis

Chemical compounds

- Powdered materials

- Solid samples

- Liquid samples

- Complex mixtures

Your Challenges, Our Solutions

Maintaining Compliance with Industry Standards

Making Accurate Decisions, Fast

Protecting the Integrity of Valuable Samples

Handling Complex Materials

Why Choose Element

Global reach, local service

Comprehensive Testing Across Materials

Advanced technology

Fast, Accurate Results Every Time

Frequently asked questions

Can Element’s XRF testing service handle trace element detection?

Yes, Our XRF testing services can detect both major constituents and trace elements in a wide range of materials. Whether you need a thorough analysis of a material's elemental composition or precise detection of minute trace elements, our XRF technology ensures accurate results.

How long does it take to get results from XRF testing?

The turnaround time for XRF testing varies depending on whether you choose portable on-site testing or in-laboratory analysis. Our portable testing offers immediate results, ideal for quick checks and decisions, while laboratory analysis typically takes longer but offers more in depth data.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

GC/MS Analysis Services

Element's GC/MS analysis offers tailored testing solutions with ISO 17025 accreditation, helping you achieve precise data insights and meet complex regulatory challenges.

Optical Emission Spectroscopy (OES) Analysis

Element's Optical Emission Spectroscopy (OES) analysis delivers precise metal composition testing in-lab or on-site. Get fast, accurate results for alloy verification and quality control with expert support.

Atomic Absorption (AA) Spectroscopy Laboratories

Accredited labs providing atomic absorption spectroscopy for precise trace element analysis. Available globally with expert support tailored to your material testing needs.

FTIR Analysis

FTIR analysis offers efficient chemical testing to identify unknown substances, polymers, and contaminants. Element provides expert insights and advanced techniques to address complex material challenges.

LECO Analysis

LECO analysis provides precise elemental testing for metals, detecting carbon, hydrogen, nitrogen, oxygen, and sulfur. Trusted by manufacturers to verify material composition and maintain quality across production stages.