Mechanical Testing Services

Accelerate your product development and ensure regulatory compliance with Element's comprehensive mechanical testing services for materials, products and components. Whether you need standard compliance testing or custom programs for complex materials, our global network of experts delivers precise, reliable results tailored to your specific project requirements.

Why Element are global leaders in Mechanical Testing

Element is a global leader in mechanical testing, delivering comprehensive solutions for both metallic and non-metallic materials, components, and specialized products. Our capabilities span everything from routine strength evaluations to advanced techniques such as abrasion resistance, fatigue and creep testing, Charpy impact analysis, and multi-axial loading. Consolidating all your mechanical testing needs with a single trusted provider simplifies your workflow, improves turnaround, and saves you valuable time.

By replicating real-world conditions - tension, compression, bending, and shear - we deliver precise insights into material performance. This allows us to assess strength, toughness, and durability under the exact demands your applications face. Controlled failure testing enables us to uncover performance limits, helping you enhance product quality, boost reliability, and reduce risk.

Element’s mechanical testing services are fully accredited to NADCAP and ISO 17025 standards, making us a trusted partner to industries such as aerospace, defense, automotive, construction, energy, medical devices, and transportation. Our global network of laboratories delivers highly customized testing programs tailored to your specific project requirements, including high-temperature testing up to 1400°C, cryogenic evaluations, and the assessment of oversized components.

No matter the complexity of the material or the demands of the application, you can count on Element for fast, accurate, and compliant results - wherever you are in the world.

Services

Aerospace Mechanical Testing

View our range of aerospace mechanical testing services for both metals and non-metals - designed to help ensure that your materials are suitable for aviation use where failure is not an option.

Physical and Mechanical Testing of Polymers for Pharmaceuticals

Element offers tailored rubber, polymer, and plastic testing services, supporting quality control, failure analysis, and product development with advanced techniques and expert insights for pharmaceuticals.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.

Compression Testing

Element's compression testing services evaluate material strength, durability, and performance under load, helping you reduce failure risk, meet standards, and improve product development. Learn More.

Mechanical Testing at Cryogenic Temperatures

Element's expert cryogenic testing services ensure the reliability and optimum performance of your materials in low temperature conditions.

Drop Weight Tear Test (DWTT) Methods

Drop weight tear testing evaluates material fracture characteristics, ensuring pipeline and pressure vessel performance in demanding environments. Expert analysis identifies brittleness, ductility, and durability under real-world conditions.

Dynamic Mechanical Analysis – DMA Analysis

Element offers DMA testing to analyse thermal and mechanical properties of non-metallic materials. We provide insights into stiffness, damping, and glass transition to enhance material performance.

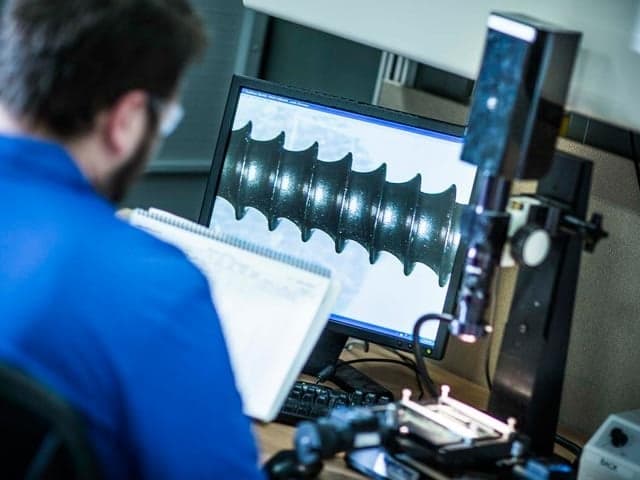

Fastener, Screw and Bolt Testing services

Element's fastener, screw, and bolt test methods are designed to evaluate every aspect of your fastener's performance, from tensile strength to rotational capacity.

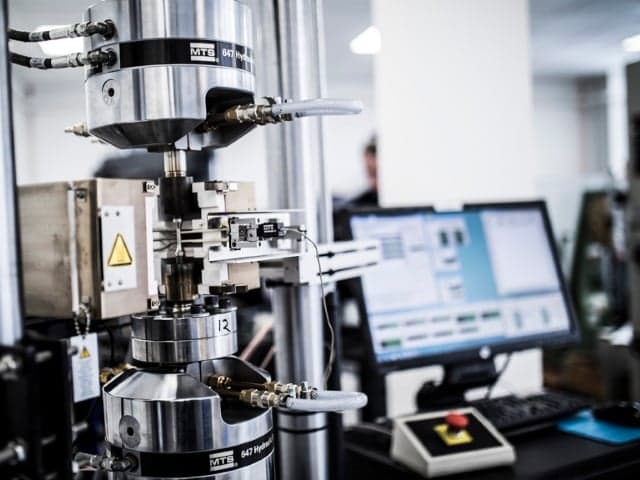

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

High Cycle Fatigue (HCF) Testing

Element offers advanced high cycle fatigue testing to meet ASTM E466 standards, preventing material failures and improving product reliability under real-world conditions. Trusted expertise for robust performance.

Low Cycle Fatigue (LCF) Testing

Element offers ASTM E606 low cycle fatigue testing, simulating high-stress environments to predict material performance and deliver precise, reliable data for informed decision-making.

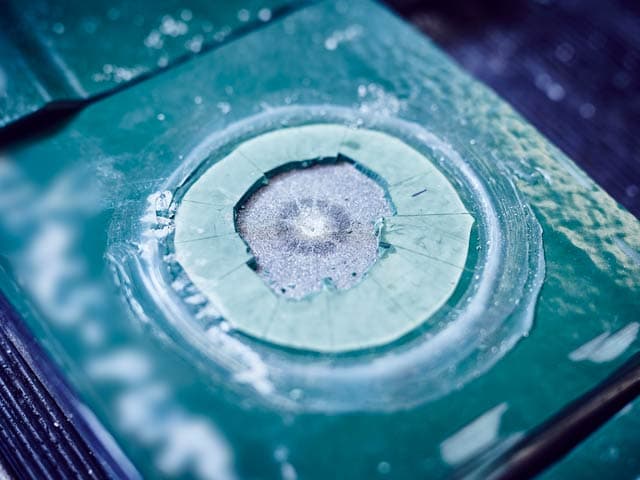

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Hardness Testing Services

Element offers comprehensive hardness testing services, including micro, macro, and hot hardness testing. With lab and on-site options, we help assess material durability for engineering, manufacturing, and compliance needs.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.

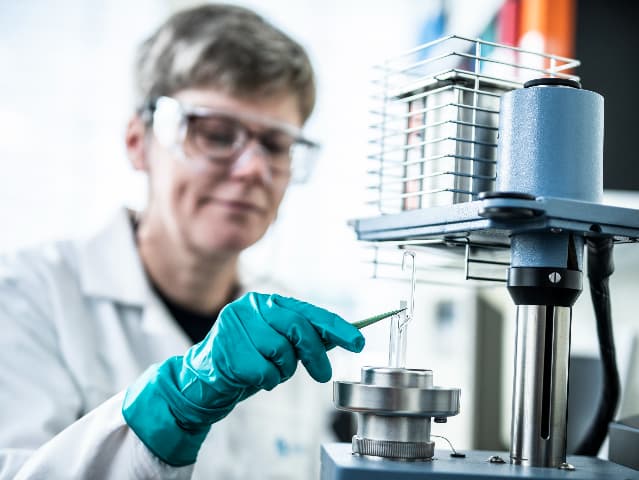

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Mechanical Testing of Polymers

Element provides precise mechanical testing of polymers, delivering critical data on strength, resistance, and durability. Our expert analysis helps industries optimize material performance and maintain compliance.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.

- Aerospace Mechanical Testing

- Physical and Mechanical Testing of Polymers for Pharmaceuticals

- Mechanical Testing of Composites

- Charpy Impact Testing Services

- Compression Testing

- Mechanical Testing at Cryogenic Temperatures

- Drop Weight Tear Test (DWTT) Methods

- Dynamic Mechanical Analysis – DMA Analysis

- Fastener, Screw and Bolt Testing services

- Fatigue Testing Services

- High Cycle Fatigue (HCF) Testing

- Low Cycle Fatigue (LCF) Testing

- Fracture Mechanics and Fracture Toughness Testing

- Hardness Testing Services

- Shear Testing

- Stress Rupture and Creep Testing

- Tensile Testing

- Mechanical Testing of Polymers

- Mechanical and Physical Testing of Coatings

- Thermomechanical Analysis (TMA)

Your Challenges, Our Solutions

Tight Project Timelines

Complex Compliance Requirements

Validating Material Performance Under Stress

Standards and Materials we test

Element provides mechanical testing to many common industries standards, including those shown below, as well as custom specifications.

Bend Testing:

- API 1104

- ASME Section IX

- ASTM A370

- ASTM A619

- ASTM E190

- ASTM E290

- AWS D1.1

- BS 4449

- ISO 5173

- ISO 7438

Charpy/Izod Impact:

- ASTM A370

- ASTM A923

- ASTM D256

- ASTM D746

- ASTM D1822

- ASTM D4812

- ASTM E23

- ISO 148

- ISO 9016

Fatigue Testing:

- ASTM D3479

- ASTM D4482

- ASTM D5528

- ASTM D6873

- ASTM D7905

- ASTM E466

- ASTM E606

- ASTM E647

- ASTM F1160

- ASTM F1800

- ISO 1143

Fracture Toughness:

- ASTM B645

- ASTM B646

- ASTM D5528

- ASTM D7905

- ASTM E370

- ASTM E399

- ASTM E1290

- BS 7448

- EN 6033

- EN 6034

Shear Testing:

- ASTM A370

- ASTM B769

- ASTM C273

- ASTM D3163

- ASTM D3518

- ASTM D5379

- ASTM D5868

- ASTM D7078

- ASTM E23

- ASTM F606

- SACMA SRM 7

- SACMA SRM 8

Tensile Testing:

- ASTM A370

- ASTM A615

- ASTM C297

- ASTM D638

- ASTM D3039

- ASTM E21

- ASTM E345

- ASTM E517

- ASTM E646

- ASTM E8

- ASTM F606

- BS EN 6892-1

- ISO 6892

- ISO 898

- ISO 8496

- NASM 1312

- SAE J1216

- SAE J429

Torque Testing:

- ASME B18

- ASTM F606

- IFI 101

- MIL-DTL-18240

- MIL-F-18240

- NASM 1312

- NASM 25027

- Metals & Metals Product

- Composites

- Plastics/Polymers

- Rubber/Elastomers

- Vinyls

- Textiles

- Organic and Non-organic Compounds

- Building Materials

- Medical Devices

- Consumer Products

Mechanical testing of steel for use within concrete structures:

- Reinforcing Steel

- Welded Steel Fabric

- Prestressing Steel

- Mechanical Couplers

- Structural Steel

- Bolts & Nuts

Why Choose Element

Bespoke testing for every material

Specialized testing for complex materials

Performance evaluation in harsh conditions

Holistic approach to material testing

But don't just take our word for it

See what others have to say about partnering with Element