What is destructive testing?

Destructive testing, also known as mechanical testing, has a pivotal role in safeguarding the quality of your products. In this article, Element expert Lee Mangham guides us through the world of destructive testing. We'll explore its importance in sectors like manufacturing, construction, and aerospace. By examining the different methods used, we aim to provide a clear understanding of how destructive testing can enhance the quality and safety of your products.

What is destructive testing?

Destructive testing is a method used to assess the strength and durability of materials by subjecting them to various loads and stresses. This approach involves intentionally pushing materials beyond their limits to observe how they behave under stress and record important data points.

The goal of destructive testing is to understand how materials perform under dynamic or static forces and to determine the point at which they fail or assess the performance at their intended loads. Engineers and researchers use this method to gather insights into crucial properties such as tensile strength, yield strength, ductility, and fatigue resilience. By conducting destructive testing, one can ensure that materials are safe for use and meet the necessary quality standards. This process helps in verifying compliance with safety regulations and contractual requirements.

Destructive testing employs various methods to evaluate different material characteristics, including tensile strength, compression strength, impact resistance, fracture toughness, and fatigue. Overall, it provides valuable information for ensuring the suitability of materials for their intended applications.

Which industries use destructive testing?

Destructive testing is used across a diverse range of industries including:

- Aerospace

- Automotive

- Construction

- Consumer

- Defense

- Energy

- Medical

- Pharmaceutical

- Oil and Gas industries.

Manufacturers, and their material suppliers, use destructive testing to gain a greater understanding of a material or product’s capabilities and limitations and ensure they comply with all the necessary industry specifications and regulations. Materials and products must be tested in conditions that replicate the environment in which they will operate. For example, the aerospace industry uses elevated tensile, creep, and stress rupture testing to simulate a high-temperature environment for materials and components including engine parts and landing gear. The construction industry, meanwhile, uses full-size component testing for items such as scaffolding couplers whilst the industrial sector uses destructive testing methods to understand the limitations of heavy equipment and machinery so that they can be confident in making the appropriate maintenance and safety operating recommendations.

Destructive testing methods

There are various types of destructive testing methods, each serving a specific purpose in assessing the mechanical properties and performance of materials. The most common ones are:

- Tension testing measures the force required to break a sample material and the extent to which the sample stretches to that breaking point.

- Torsion testing assesses how a product or material will respond to the stress of repeated twisting motion.

- Compression testing applies compressive pressure to a test sample to determine the material’s behavior under applied crushing loads.

- Tensile testing subjects a sample to a controlled uniaxial tension until failure to provide data on the strength, stiffness, and ductility of a material. It is most commonly used for obtaining the mechanical characteristics of materials such as metals and polymers.

- Shear testing applies force to a material in a parallel or torsional direction, rather than holding it in tension until the materials shears apart. The point at which the sample fails is defined as its shear strength. Shear testing is particularly important for materials that might experience a multi-directional force, such as fasteners.

- Hardness testing presses a specifically dimensioned and loaded object into the surface of a material to calculate the hardness by measuring the force applied and comparing it to a geometrical aspect of the indentation such as the surface area or depth. The three most common hardness tests are the Brinell test, the Vicker's Diamond test, and the Rockwell test.

- Creep testing is used to determine the long-term strength and heat resistance of a material by applying a constant stress at a constant temperature to the sample. The test is then recorded on a graph of strain versus time.

- Stress rupture testing, similar to creep testing, is used to determine the long-term strength and heat resistance of a material by applying a constant stress at a constant temperature until rupture occurs.

- Charpy impact testing measures a material’s toughness, the ability to absorb energy, and resistance to brittle fracture. Also known as the Charpy V-notch test, Charpy impact testing measures the amount of energy that a material can absorb as it fractures to predict how the material will react to impact loading. It is used to test samples at a low temperature.

- Izod impact strength testing determines the impact resistance of materials and, like the Charpy test, is used to test materials at a low temperature. The Izod impact test consists of a pendulum with a determined weight at the end of its arm swinging down and striking a specimen held securely in a vertical position. The impact strength is determined by the loss of energy of the pendulum by precisely measuring the loss of height in the pendulum's swing.

- Cyclic fatigue testing analyses a material’s ability to withstand cyclic fatigue loading conditions by repeated loading and unloading in tension, compression, bending, torsion, or a combination of these stresses.

- Proof load testing applies controlled force for a definite time interval to load-bearing equipment to ensure it is safe to use within the minimum allowable working load. It is frequently used to verify the quality of items such as bolts and fasteners.

Many of the methods, such as tensile, stress rupture, creep rupture, fatigue, and impact testing, can evaluate how the material will behave in extreme environments such as subzero and elevated temperatures. All the tests are carried out to global specifications, such as BS EN, EN ISO, or ASTM, as stipulated by suppliers’ material specifications.

What is the difference between destructive and non-destructive testing?

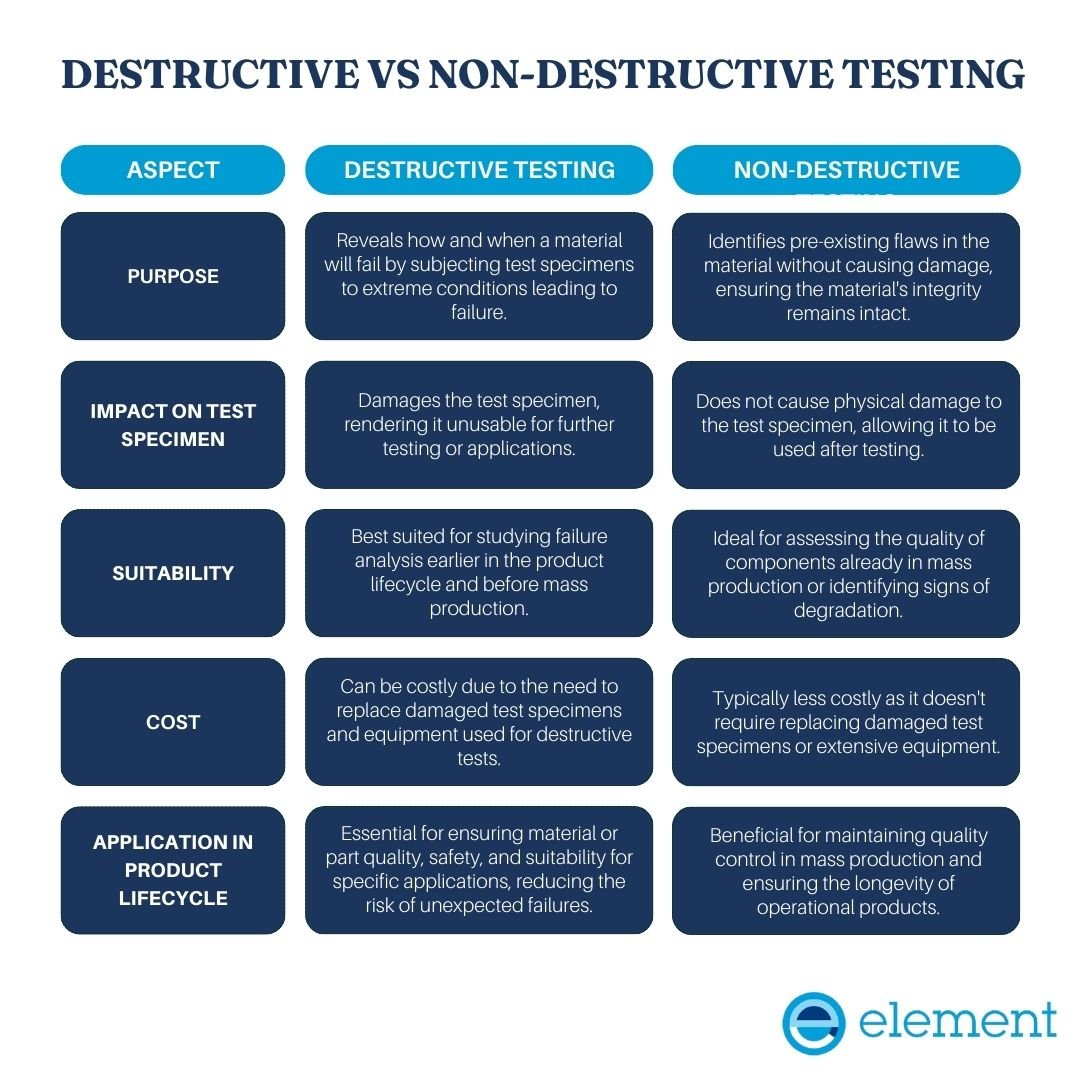

Destructive tests show how and when a material will fail whilst non-destructive tests highlight pre-existing flaws in the material, such as cracks or corrosions, that indicate it could fail in the future.

As destructive testing can only be conducted by damaging the test specimen, it can be costly for the manufacturer. Non-destructive testing does not cause any physical damage and therefore allows the specimen to be used after testing has been completed. This means that non-destructive testing is more suited for checking the quality of components and products already in mass production or identifying signs of degradation to ensure the correct maintenance requirements of products already in operation are met.

Destructive testing is more suited to studying failure analysis much earlier in the product lifecycle and prior to mass production. Whilst destructive testing typically requires more of an initial outlay earlier in a product’s lifecycle than non-destructive testing, its ability to ensure a material or part’s quality, safety, and suitability for an application can greatly reduce the risk of expensive, potentially dangerous, or catastrophic, unexpected failures in-service.

Conclusion

Destructive testing serves as a crucial method for evaluating the strength, durability, and performance of materials across various industries. By subjecting materials to extreme loads and stresses, you can gather valuable data on properties such as tensile strength, ductility, and fatigue resilience. Industries ranging from aerospace to construction utilize destructive testing to ensure compliance with safety regulations and quality standards. Our global network spans laboratories across the US, UK, Europe, Middle East, and Asia offering NADCAP and ISO 17025-accredited mechanical testing services. With extensive experience supporting critical industries globally, we tackle even the most challenging projects, regardless of the material.

To learn more about Element's credentials, please visit our About Us page. For more information about our mechanical/destructive testing services, contact an expert today.