Understanding your Creep and Stress Rupture Testing

This article by Element explains creep and stress rupture testing, showing how to evaluate material performance under constant stress and high temperatures.

Creep damage is an everyday reality, affecting almost everything around us in some way. It is constant, irreversible, and mainly affects equipment subjected to continuous, elevated temperatures during its normal service life. In fact, the higher the temperature, the greater the potential for damage.

Material performance during its life cycle is critical in ensuring that plant and machinery perform toward, and perhaps even beyond, their design life. This is particularly critical when considering components that are subjected to stresses at higher temperatures. Creep and stress rupture tests help our customers understand the effects of long-term stress on materials to prevent product failures. This data is critical for products used in aerospace, oil & gas, power generation, and many other industries.

Creep and stress rupture test methods

Creep and stress rupture tests determine the amount of strain developed in material over a long period at elevated temperatures under applied constant load or stress.

The creep test analyses the deformation (creep) of a metal or composite when subjected to long-term exposure to levels of stress at a constant temperature. The rate of this deformation is a function of the material properties, exposure time, exposure temperature, and the applied structural load.

Creep and stress rupture tests are used to monitor the deformation of a specimen and the time to rupture. Deformation during a creep and stress rupture test is much greater than the one developed during a creep test.

Stress rupture tests focus on measuring the time necessary for the specimen to rupture.

What are creep and stress rupture tests used for?

Both creep and stress rupture tests provide designers factual data on the service life conditions. The creep test provides information on the deformation of material as a function of time when subjected to a continuous loading at a particular temperature.

Stress rupture tests provide the load-carrying ability of material subjected to constant stress at elevated temperatures over a long time. There is an onset of voids due to constant load and temperature; some materials are specifically engineered to withstand such conditions. The two tests give designers factual data on the service life conditions.

The rupture life of notched specimens is used to simulate stress concentration in actual service. These notches create triaxial stresses and greatly reduce the time of test, compared to test without a notch.

Creep and stress rupture test reports

Creep and stress rupture test methods list the information which should be included in reports of tests. Reports contain the following information:

1. Results from stress rupture tests:

- Type of alloy

- Specimen description that will provide traceability back to manufacture.

- Product identification

- Heat treatment

- Test temperature, °C (°F)

- Stress, MPa (KSI)

- Specimen dimensions

- Test duration, to nearest 0.1 h for test durations of 100 h or less and to nearest 1.0 h for test durations over 100 h

- Maximum extension measured

- Reduction of area (%)

- The location and description of the fracture

- Stress for rupture in times indicated: 1, 10, 100, 1000, 10 000, 100 000 h.

2. Results from creep rupture tests:

- Type of alloy

- Specimen description that will provide traceability back to melting

- Product size

- Heat treatment

- Test temperature, °C (°F)

- Stress, MPa (KSI)

- Specimen dimensions

- The total strain on the application of force.

- For tests halted before rupture, elastic contraction when the force was removed

- Test duration, to nearest 0.1 h for test durations of 100 h or less and to nearest 1.0 h for test durations over 100 h

- The average ambient temperature in the laboratory during the duration of the test

- Average percent relative humidity during the test duration

- Temperature excursions are greater than allowable limits

- Strain—A plot on Cartesian coordinates of total strain versus time and a plot of creep versus time on logarithmic coordinates

- Time to nearest 0.1 h for strains occurring at 100 h and less, to nearest 1.0 h for strains occurring at over 100 h for those of the following total strains included in the tested range, 0.1, 0.2, 0.5, 1.0, 2.0, and 5.0 %

- If the test was continued into the tertiary creep stage: (1) minimum creep rate (%) per hour, (2) strain at the intercept of the tangent at minimum creep rate with the strain axis at zero time (Cartesian coordinates), (3) time at the start of secondary creep, and (4) time at the end of secondary creep

- Total plastic strain and time to nearest 0.1 h for test durations of 100 h or less and to nearest 1.0 h for test durations over 100 h at the termination of the test.

The Element advantage

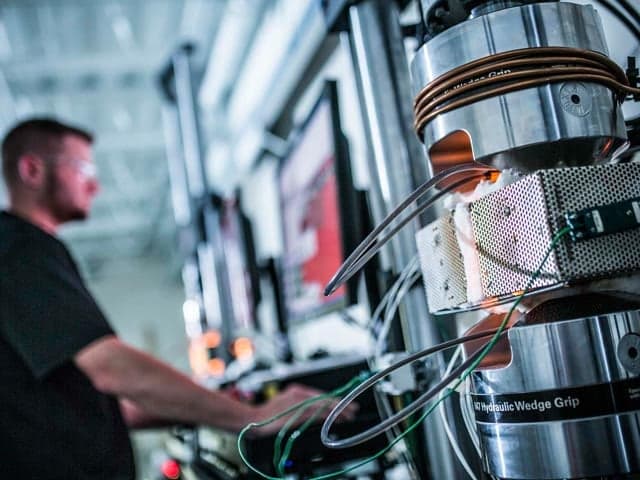

Within the Element network, several of our ISO 17025 and Nadcap accredited testing laboratories in North America, Europe, India, and Asia provide the highest quality creep and stress rupture testing services to clients across many sectors.

We have vast experience in delivering creep and stress rupture testing at fully equipped in-house machine shops and offer solutions for various sample configurations and associated tests to prove the evidence/onset of creep.

For more information on creep and stress rupture testing or to speak with one of our experts, contact us today.

Related Services

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.