Oil and Gas Testing

At Element, we provide tailored oil and gas testing services to ensure the safety, reliability, and compliance of your oil and gas infrastructure. Our comprehensive testing solutions help you meet regulatory standards, reduce downtime, and extend the life of critical assets across upstream, midstream, and downstream markets. With decades of expertise, cutting-edge technology, and global accredited facilities, we partner with you to safeguard your operations in the toughest environments - all while saving you time and money.

What is Oil and Gas Testing at Element?

Oil and gas testing addresses the complex challenges of searching for, extracting, and transporting oil and gas reserves in a reliable, efficient, and safe way. At Element, our oil and gas infrastructure testing services include a wide range of solutions that ensure the safety, performance, and longevity of your critical energy infrastructure. From offshore rigs to pipelines and refineries, we provide expert testing in materials durability, corrosion resistance, weld quality, and structural integrity – plus more specialized services, including mechanical testing at cryogenic temperatures and determining the composition of natural gas - helping you optimize your operations while minimizing risks.

What can Element offer you for Oil and Gas Testing?

Key tests offered

Key tests offered

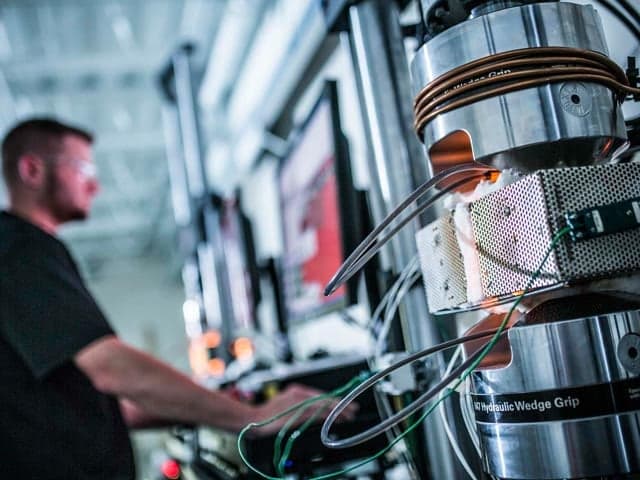

Element utilizes advanced testing methods like non-destructive testing (NDT), corrosion testing, mechanical testing, fatigue analysis, and fracture mechanics. Our specialized engineering services include Engineering Critical Analysis (ECA), Finite Element Analysis (FEA), Failure Analysis, fracture mechanics and toughness testing in sour environments and Fitness For Service (FFS) assessments. Our solutions are designed to address your specific challenges, such as pipeline integrity and offshore drilling, plus prevent downtime, extend asset lifespan, and meet industry-specific regulatory requirements across upstream, midstream, and downstream operations.

Components and materials we test

Components and materials we test

We specialize in testing a wide variety of materials critical to oil and gas infrastructure, including metals, polymers, elastomers, and composite materials. Our expertise spans everything from rigs and pipelines to refineries and storage tanks, plus specialized components like steel catenary risers for offshore applications, ensuring every part of your infrastructure is tested for optimal safety and reliability.

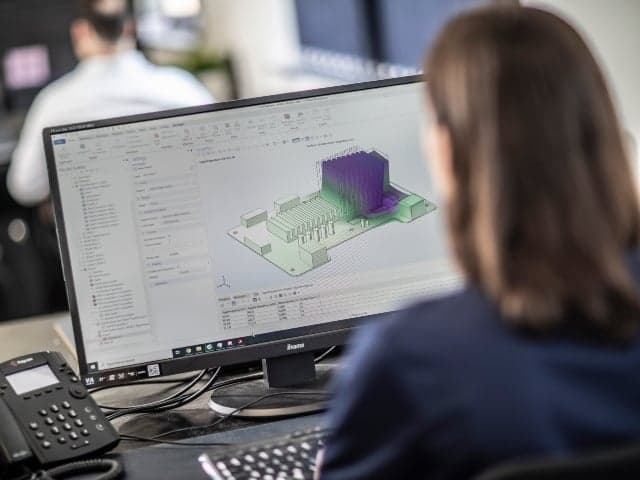

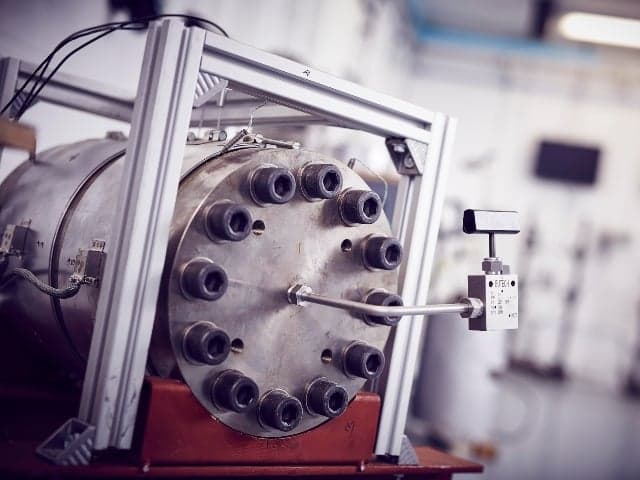

Cutting-edge equipment we use

Cutting-edge equipment we use

We employ state-of-the-art equipment including cryogenic testing tools, advanced corrosion analysis instruments, and full-scale pipe testing rigs. This ensures accurate, precise results for testing infrastructure in even the most extreme offshore or deep-sea environments, reducing your operational risks and maximizing the reliability of your assets.

Which labs offer this service

Which labs offer this service

With a global network of ISO-accredited laboratories, Element provides testing services in regions including Europe, North America, the Middle East, and Asia. Our local expertise and rapid turnaround times, combined with our specialized offshore testing capabilities, ensure that your projects receive the support they need, wherever you operate.

Managing complex engineering challenges

Managing complex engineering challenges

From design phase through production and service, our Engineering Critical Analysis (ECA) and Finite Element Analysis (FEA) services help you solve complex structural and mechanical engineering problems, ensuring your infrastructure performs reliably throughout its lifecycle.

Materials and products we test

- Rigs

- Catenary risers

- Pipes & pipeline systems

- Refineries

- Tanks

- Offshore platforms

- Welds & joints

- Storage tanks

- Structural components

- Non-metallic materials (polymers, elastomers)

- Composites

- Construction materials (e.g., for pipelines)

Your Challenges, Our Solutions

Ensuring Safety and Reliability

Regulatory Compliance

Minimizing Downtime

Managing Corrosion and Harsh Environments

Element Experts at your service

Why Choose Element

Local Expertise, Global Scale

Rapid Turnaround

Specialized Offshore Testing

State-of-the-Art Technology

8,500engaged experts

270+laboratories

Decades of testing experience

ISO/IEC 17025 full accreditation for energy testing

Frequently Asked Questions

How can Element help reduce downtime during testing?

Element uses non-destructive testing (NDT) methods to quickly and safely inspect infrastructure without causing downtime. This enables your operations to continue while we assess materials for integrity and safety.

What are the benefits of Element’s testing for pipeline integrity?

Element tests pipelines for corrosion, fatigue, and weld quality. Our solutions help identify risks early, reducing the likelihood of leaks or failures and ensuring compliance with industry standards.

How do you ensure compliance with local regulations?

Element adheres to ISO standards and local regulatory frameworks for each region, ensuring your infrastructure meets all required safety and environmental regulations.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Fitness for Service (FFS) Assessments

Element's Fitness for Service assessments ensure equipment safety, minimize risks, and prevent costly failures. We deliver reliable evaluations to help you make informed run-repair-replace decisions across your equipment's lifecycle.

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Full and Small Scale Pipe Testing

Element provides full-scale pipe testing services to evaluate in-service behavior of your assets and determined potential failure conditions.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Immersion Ultrasonic Testing (IUT) Services for Oil & Gas

Element's Immersion Ultrasonic Testing (IUT) services provide precise defect detection for pipeline girth welds, ensuring structural integrity and compliance. Using advanced technology and industry standards, our experts help minimize repair costs and enhance reliability for the oil and gas industry.

Root Cause Analysis for the Oil & Gas Industry

Element provides expert root cause analysis for the oil & gas industry, identifying failure causes in assets like pipelines, pumps, and seals. Our services ensure compliance, safety, and operational continuity with precise insights and solutions.

IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

Element provides IMO PSPC coatings testing for seawater ballast and cargo oil tanks, simulating real-world conditions to verify compliance, prevent corrosion, and optimize coating performance.

Environmental Impact Assessments Services

Element's Environmental Impact Assessments provide air, noise, and vibration studies to meet planning and regulatory needs. Backed by advanced modeling and independent verification, we deliver accurate results to protect communities, ensure compliance, and streamline your project planning.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

- Finite Element Analysis (FEA) Services

- Fitness for Service (FFS) Assessments

- Oil and Gas Corrosion Testing Services

- Full and Small Scale Pipe Testing

- Oil & Gas Weld Testing Services

- Immersion Ultrasonic Testing (IUT) Services for Oil & Gas

- Root Cause Analysis for the Oil & Gas Industry

- IMO PSPC Coatings Testing of Seawater Ballast Tanks and Cargo Oil Tank

- Environmental Impact Assessments Services

- Non-Destructive Testing (NDT) and Inspection Services

- Mechanical Testing Services

- Fracture Mechanics and Fracture Toughness Testing

- Fatigue Testing Services