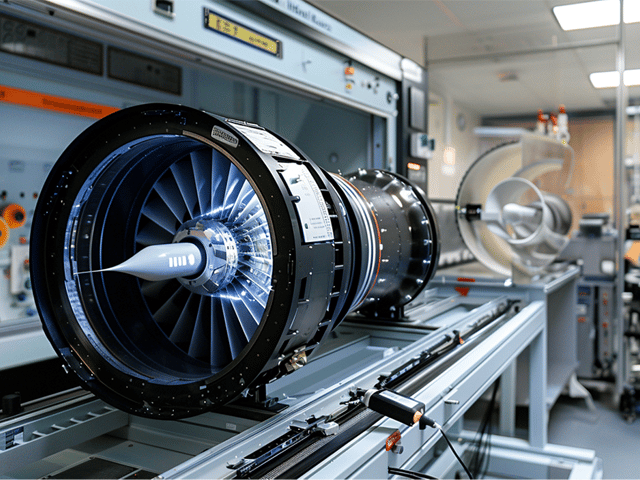

Test Rig Design Services

Minimize product failures and accelerate time to market with Elements' fully tailored, end-to-end test rig design services. We offer hands-on engineering guidance, simulate real-world conditions, and integrate cutting-edge technology for precise, reliable results. Trust Element Digital Engineering to optimize your testing process—from concept to launch—with speed, convenience, and unmatched technical partnership.

What is Test Rig Design at Element?

Test rig design services at Element provide custom testing environments that evaluate product performance and durability under controlled conditions. Our engineering team works closely with you to design bespoke test rigs that replicate specific operational environments across aerospace, defense, energy, automotive, and technology sectors, ensuring thorough testing according to industry standards.

What can Element offer you for Test Rig Design Services?

Key services offered

Key services offered

Element delivers end-to-end test rig solutions, from initial concept through to detailed engineering, implementation and project management. By collaborating closely with you, we ensure each rig meets your unique testing requirements and industry standards. Our services also include advanced simulation capabilities, technology integration, comprehensive installation and calibration, and ongoing support. When required, we leverage data science insights to refine design decisions and optimize performance.

Ongoing Lifecycle and Fatigue Testing: Our services include continuous testing to assess product durability and lifespan under repeated stress, helping you optimize design and material choices throughout the development process.

Products we test

Products we test

Elements' test rigs are designed to evaluate performance across multiple industries, from aerospace components to automotive systems. We specialize in creating custom environments that simulate real-world conditions, ensuring comprehensive testing of your specific products. Our rigs accommodate various material types and component sizes, with expertise in mechanical, environmental, and durability testing.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our test rigs incorporate state-of-the-art sensors, data acquisition systems, and control technologies for maximum accuracy and reliability. Advanced instrumentation ensures precise data collection and real-time performance monitoring, giving you comprehensive testing capabilities and consistent results.

Which labs offer this service

Which labs offer this service

Our Bristol, Derby, and Houston digital engineering hubs provide global access to our expert capabilities. Find out where your nearest digital engineering hub is on our Locations Page.

Ongoing Lifecycle Support

Ongoing Lifecycle Support

Our partnership extends beyond installation — we offer comprehensive lifecycle support. That includes regular maintenance services, recalibration when required, and adaptation of test rigs to meet evolving testing needs. Our team can ensure your testing capabilities stay up to date with industry requirements and technological advancements.

Standards we test to and components we test

Our testing and certification processes align with numerous international and national standards to ensure our products meet the highest levels of quality and safety. Below is a detailed list of the standards we adhere to:

Aviation Standards:

- EASA (European Union Aviation Safety Agency): Ensures safety and environmental protection in the European aviation sector.

- CAA (Civil Aviation Authority): Governing body regulating aviation safety in the UK.

- FAA (Federal Aviation Administration): Oversees all aspects of American civil aviation.

- UK CA (UK Civil Aviation Authority): Ensures that the UK aviation industry meets the highest safety standards.

British Standards:

- British Standards: Specifications designed to ensure quality and efficiency across multiple industries in the UK.

European Standards:

- EEC CE Marking: Certification mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- DIN Standards (Deutsches Institut für Normung): German standards that ensure quality, safety, and efficiency.

American Standards:

- ASME Standards (American Society of Mechanical Engineers): Promotes the art, science and practice of multidisciplinary engineering around the globe.

- ANSI (American National Standards Institute): Oversees the creation, promulgation, and use of thousands of norms and guidelines that directly impact businesses in nearly every sector.

Chinese Standards:

- Chinese GB Standards: Mandatory standards that are the basis of product quality in China.

Indian Standards:

- ISI (Indian Standards Institute): Quality standards used to maintain product efficiency and performance in India.

- By adhering to these standards, we ensure that our products are not only compliant with regulatory requirements but also meet the highest standards of safety and quality globally. If you require more details about specific standards or need information on how we implement these standards in our processes, please feel free to reach out to us.

Parts, materials and components we test

- Aerospace components

- Defense components

- Automotive parts

- Technology products

- Environmental simulation materials

- Mechanical components

- Fatigue testing materials

- Lifecycle testing products

- Performance validation materials

Your Challenges, Our Solutions

Risk Management

Complex Testing Requirements

Accuracy Concerns

Technical Integration

Why Choose Element

Precision Engineering

Customized Solutions

Advanced Technology Integration

Reduced Risk

Frequently asked questions

Can your test rigs simulate any testing environment?

Our test rigs are engineered to simulate a wide range of environmental conditions, so no matter what your specific operational scenarios, they’ll replicate them.

How do you ensure test rig accuracy?

We have rigorous calibration and validation processes in place, using advanced technology and instrumentation for high precision and reliability.

Can you upgrade existing test rigs?

Yes, we specialize in upgrading and retrofitting existing test rigs to meet new industry standards, enhancing functionality and extending service life.

What ongoing support do you provide for test rigs?

We provide comprehensive post-installation support including maintenance, recalibration services, and adaptation to new testing needs as they evolve. Our commitment extends beyond initial setup to ensure your test rig maintains optimal performance throughout its lifecycle.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Project Management for Product Testing Services

Streamline your product testing with our expert project management, ensuring rigorous and efficient industry compliance.

Prototype Design and Development Services

Discover comprehensive solutions in prototype design and development services for fluid systems, from concept to testing; ensuring rapid timelines, stringent standards compliance, and exceptional reliability.