Composite Sandwich Panel Test Methods

Get precise, reliable insights into the strength, durability, and compliance of your composite sandwich panels with Element’s composite sandwich panel testing services. Whether you’re in aerospace, automotive, or renewable energy, we help ensure your materials meet the demands of real-world performance and strict regulatory standards.

What is Composite Sandwich Panel Testing at Element?

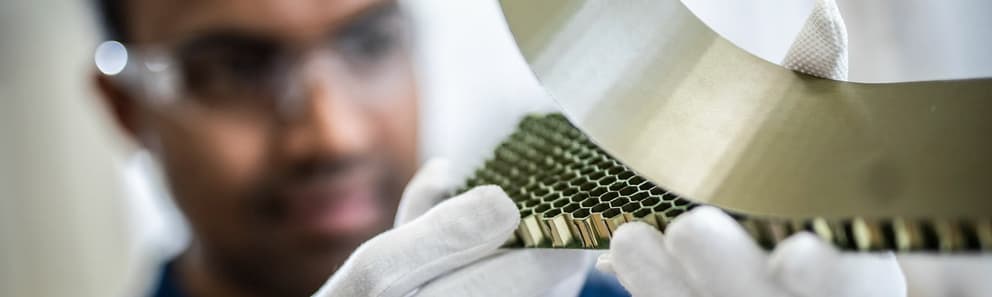

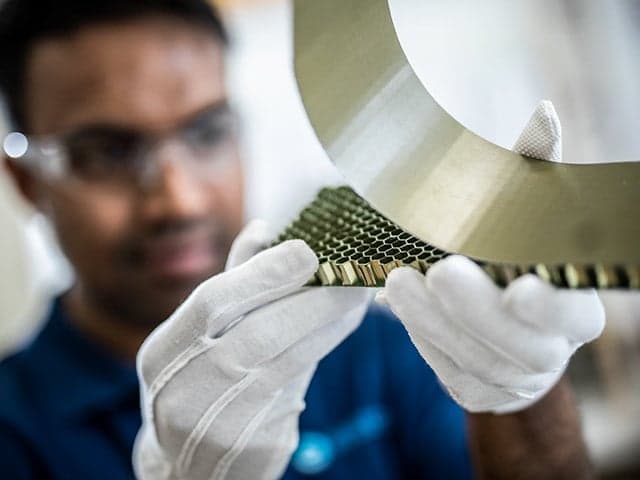

Composite sandwich panels combine thin, stiff face sheets bonded to lightweight cores, creating structures with exceptional strength-to-weight ratios. At Element, we provide mechanical testing services specifically designed to evaluate these complex constructs as complete units, measuring critical properties including tensile strength, shear resistance, compression behavior, and bonding integrity—essential data for applications demanding both performance and weight reduction.

What Can Element Offer You For Composite Sandwich Panel Test Methods?

Key Tests Offered

Key Tests Offered

We deliver a comprehensive suite of mechanical tests tailored to sandwich structures, giving you actionable data for compliance and performance verification.

Our test capabilities include:

- Flatwise tensile (ASTM C297)

- Core shear / plate shear (ASTM C273)

- Bending (ASTM C393)

- In-plane and out-of-plane compression (ASTM C364/C365)

- Adhesive bond peel (ASTM D1781)

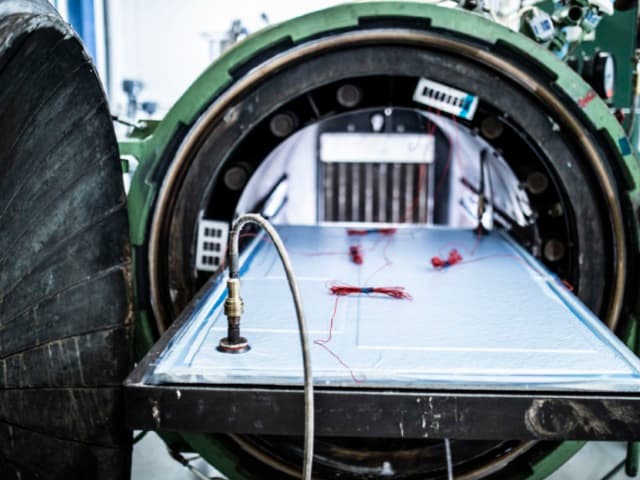

- Fatigue testing with impact flaws for damage growth assessment

Components and Materials We Test

Components and Materials We Test

Element tests complete sandwich panel constructs, ensuring all layers are represented—from outer skin to core and adhesive. This means you get real-world insights into how the full system performs, not just isolated components.

We test:

- Composite sandwich panels (combined skin and core)

- Lightweight core materials (e.g., honeycomb, foam)

- Face sheets / outer skins

- Adhesive bond layers

Methods and Solutions Offered

Methods and Solutions Offered

Our experts execute testing using industry-standard ASTM methods, with configurations designed to replicate service conditions. Whether you need quality control, certification, or performance diagnostics, we tailor our approach to your specific project goals.

Solutions include:

- Realistic failure analysis (core, skin, adhesive)

- Picture frame configurations for in-plane shear

- Testing specimens at various spans and loads

- Development of next-gen peel testing methodologies

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Element uses advanced testing rigs and fixturing to simulate operational forces accurately. Our labs are equipped for both standard and high-load testing, ensuring we can handle panels of all sizes and performance needs.

Our equipment includes:

- Load frames for high-force tensile and compression

- Climbing drum peel fixtures

- Picture frame shear setups

- Custom jigs for variable span bend testing

Standards we test to and materials we test

- ASTM C297 (Out of plane/Flatwise tensile)

- ASTM C273 (Core shear/Plate shear testing)

- ASTM C393 (Bend testing sandwich materials)

- ASTM C364 (In-plane/edgewise compression)

- ASTM C365 (Out-of-plane/flatwise compression)

- ASTM D1781 (Adhesive bond testing)

Core materials

- Honeycomb cores

- Foam cores

- Balsa cores

Face sheet materials

- Carbon fiber face sheets

- Fiberglass face sheets

- Aluminum face sheets

Complete sandwich constructs

- Sandwich panels with impact damage

- Sandwich panels with deliberate flaws

- Sandwich materials for fatigue testing

Your Challenges, Our Solutions

Simulating Real-World Conditions

Ensuring ASTM Compliance

Testing Full Panel Constructs

Verifying Bond Integrity

Why Choose Element

Sandwich panel testing expertise

Industry-specific test applications

Comprehensive mechanical evaluation

Custom test method development

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

- Aerospace Composite Testing

- Composites Testing

- Shear Testing

- Tensile Testing

- Flexural Testing for Composite Materials

- Mechanical Testing of Composites

- Composite Curing Autoclave & Fabrication

- Composite Damage Tolerance Testing

- Testing Environmental Effects on Composites

- Examining Fiber-Reinforced Composite Materials