Automotive Buzz, Squeak, and Rattle (BSR) Testing

Partner with Element for industry-leading automotive Buzz, Squeak and Rattle (BSR) testing that sets the benchmark for precision and capability. Our 700lb capacity silent shaker, 12-channel acoustic system, and 4-axis simulation deliver unmatched accuracy in noise identification. With rapid turnaround times and specialized EV acoustic expertise, we help you prevent costly warranty claims while enhancing your brand's reputation for quality.

What is Automotive Buzz, Squeak, and Rattle (BSR) Testing at Element?

BSR testing evaluates automotive components for unwanted noises that occur during normal vehicle operation. At Element, we provide comprehensive BSR testing in semi-anechoic chambers using advanced multiaxial silent shakers that precisely replicate real-world driving conditions. A quiet ride is one of the hallmarks of a quality vehicle, and our testing allows manufacturers to modify designs before components become consumer problems or warranty issues. This testing is crucial for both electric vehicles with no engine noise and modern, quieter internal combustion engines where even minor unwanted sounds are noticeable.

What Can Element Offer You For Automotive BSR Testing?

Key tests offered

Key tests offered

At Element, we conduct precise multi-axis simulations that replicate real-world driving scenarios in our semi-anechoic chamber. Our testing identifies sources of buzzing, squeaking, and rattling under various conditions including different speeds, road surfaces, and temperature variations. Our industry-leading sequential 4-axis testing mimics actual road conditions to provide accurate predictions of noise issues before they reach consumers.

- Multiaxis vertical pitch and roll testing

- Sequential 4-axis testing

- Acoustic data collection and analysis

- Noise source identification

- Component durability under vibration conditions

Additional NVH testing capabilities

Beyond BSR testing, Element offers comprehensive Noise, Vibration, and Harshness (NVH) testing including sound power/intensity measurement, natural frequency analysis, pass-by noise testing, sound quality evaluation, and specialized testing in our drive-in hemi-anechoic chamber. These complementary services provide a complete acoustic performance profile for your vehicle components.

- Sound power/intensity analysis

- Natural frequency analysis

- Pass-by noise and sound quality testing

- Additional single-axis BSR analysis

Drive-in semi-anechoic chamber testing

Components we test

Components we test

Our versatile 700lb capacity silent shaker accommodates a wide range of automotive components from small interior parts to entire vehicle sections. The large 6ft x 40in testing table handles oversized parts that most facilities cannot test, while still maintaining precision for smaller assemblies. To help you get to market faster, we can configure multiple smaller components simultaneously to reduce your testing timeline and improve efficiency.

- Consoles and instrument panels

- Door assemblies and mechanisms

- Complete seat rows and seating systems

- Quarter car bodies

- Interior trim components

Methods and solutions offered

Methods and solutions offered

Our advanced twelve-channel sound collection system precisely pinpoints noise sources within complex automotive assemblies. Our testing methodology not only identifies unwanted sounds but helps determine their root causes, allowing your engineering team to implement effective solutions quickly. With typically faster turnaround times than competitors, we provide detailed reports with specific recommendations for design modifications to eliminate noise issues.

- Semi-anechoic chamber testing environment

- 12-channel acoustic data collection

- Precise noise source identification

- Root cause analysis

- Design modification recommendations

Cutting-edge equipment we use

Cutting-edge equipment we use

Element Warren houses one of the largest silent shakers in the Midwest with a 700lb weight capacity and 6ft x 40in table. Our multi-axial simulation table (MAST) delivers vertical pitch and roll testing along with sequential 4-axis movement. The hemi-anechoic chamber equipped with twelve 1/2 inch pre-polarized free-field microphones ensures precise acoustic data collection for rapid source localization.

- 700lb silent shaker system

- 6ft x 40in table with multiple extensions

- Hemi-anechoic testing chamber

- Twelve 1/2-inch pre-polarized free-field microphones

- Multi-axial simulation tables (MASTs)

Which labs offer this service

Which labs offer this service

Our specialized BSR testing capabilities are available at Element Warren, featuring one of the USA Midwest's largest silent shaker systems. This facility combines advanced testing equipment with industry-leading expertise to deliver comprehensive BSR solutions for automotive manufacturers worldwide.

Standards we test to and components we test

- GMW14011

- CETP: 01.10-L-413

- Consoles and instrument panels

- Door assemblies and structures

- Complete seat rows and seating systems

- Quarter car bodies

- Interior trim components

Your Challenges, Our Solutions

Consumer expectation for quiet vehicles

Warranty claims and recalls

Precise diagnosis required for complex assemblies

Tight production schedules

Why Choose Element

Industry-leading component capacity

Authentic driving condition simulation

Precise acoustic source identification

Comprehensive NVH testing solutions

700lbcapacity

6ft x 40intable

12specialized microphones

4-axissimulation

But don't just take our word for it

See what others want to say about ...

Frequently asked questions

How does Element's BSR testing process work?

Once you engage with our team, we establish your specific testing needs and priorities. Your components are then mounted to our silent shaker in our hemi-anechoic chamber, where they undergo systematic multiaxial vibration testing while our 12-channel acoustic system captures and analyzes all sound data. You'll receive a comprehensive report identifying noise sources and recommended solutions within an agreed timeframe.

Why is BSR testing more important for electric vehicles?

Electric vehicles produce no engine noise to mask unwanted sounds from components. Without this acoustic masking, even minor squeaks or rattles become highly noticeable to drivers and passengers, significantly impacting perceived quality and customer satisfaction. As more consumers shift to EVs, expectations for interior quietness have increased dramatically, making BSR testing an essential quality control measure.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Multi-Axial Simulation Table (MAST) Testing Services

Element's MAST testing replicates real-world vibrations in a controlled lab, helping automotive engineers assess durability, reduce development time, and refine vehicle components for safer, more reliable performance.

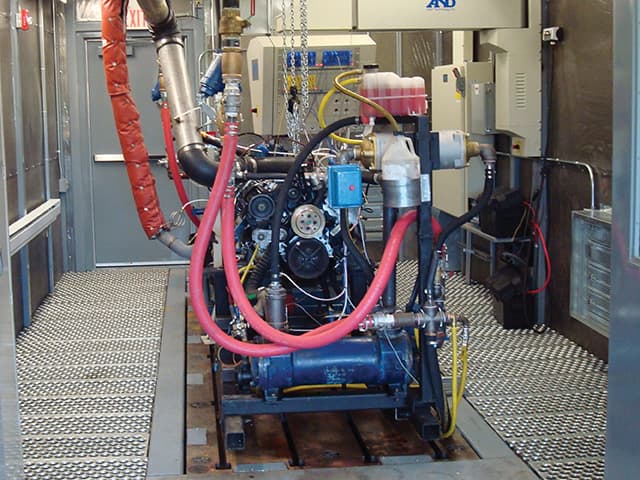

Automotive Dynamometer Testing Services

Gauge the performance and durability of your automotive drivetrain components with dynamometer testing from Element, the industry's most trusted third-party testing partner.

Automotive Weathering Testing

Element's automotive weathering testing evaluates material durability against heat, moisture, and UV exposure, helping manufacturers prevent degradation, extend product lifespan, and meet industry standards.

Full Vehicle Durability Testing

Element offers full vehicle durability testing, simulating real-world conditions in a lab to detect defects early, improve reliability, and support manufacturers in developing safer, long-lasting vehicles.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.