Pipeline and Field Joint Coatings

Your pipeline integrity depends on effective coating protection. Prevent costly corrosion and extend infrastructure lifespan with comprehensive Pipeline and Field Joint Coatings testing. Navigate complex industry standards with confidence while ensuring your subsea and onshore assets withstand the harshest environmental conditions throughout their design life.

What is Pipeline and Field Joint Coatings testing at Element?

Pipeline and field joint coatings testing evaluates protective materials that shield pipelines from corrosion and environmental damage. At Element, we provide comprehensive testing services that assess coating performance against extreme conditions, focusing particularly on field joints—often the most vulnerable areas where pipeline segments are welded together. Our testing validates that your coating solutions will maintain structural integrity throughout the pipeline's intended service life at Element.

What Can Element Offer You For Pipeline and Field Joint Coatings Testing?

Key tests offered

Key tests offered

Element's comprehensive testing capabilities help you validate coating performance across multiple critical parameters. We conduct thorough evaluations, including holiday detection to identify coating discontinuities, peel strength and adhesion testing to confirm proper bonding, and cathodic disbondment to assess protection under current flows. Additional specialized tests include water immersion resistance, lap shear strength, impact and indentation resistance, and flexibility - all crucial for predicting real-world performance.

- Holiday detection for coating integrity

- Peel strength and adhesion testing

- Water immersion resistance

- Lap shear resistance measurement

- Cathodic disbondment evaluation

- Impact resistance testing

- Indentation resistance

- Flexibility assessment

Materials we test

Materials we test

Element tests a comprehensive range of pipeline and field joint coating materials to ensure optimal protection for your assets. Our expertise covers everything from traditional hot-applied bituminous tapes to advanced three-layer coating systems, ensuring we can validate the performance of virtually any coating solution you implement. We specialize in testing materials designed for the most challenging offshore and onshore environments.

- Hot-Applied Bituminous Tapes

- Cold-Applied Polymeric Tapes

- Petrolatum and Wax Tapes

- Polyethylenes (PE) and Polypropylenes (PP)

- Heat-Shrinkable Sleeves

- Fusion-Bonded Epoxies (FBE)

- Liquid Epoxies and Polyurethanes (PUR)

- Flame-Sprayed Polyolefins

- Three-Layer Coating Systems (3LPE, 3LPP, 3LPO)

Methods and solutions offered

Methods and solutions offered

Element's methodical approach to pipeline coating validation ensures comprehensive quality assessment throughout your project lifecycle. We conduct testing at every critical phase, from initial application procedure specification through pre-qualification trials (PQT) and pre-production trials (PPT). Our experts develop detailed inspection and testing plans that clearly differentiate between quality assurance and quality control requirements, ensuring your coating solutions meet all performance criteria.

- Application procedure specification development

- Pre-qualification trial (PQT) testing

- Pre-production trial (PPT) evaluation

- Comprehensive inspection and testing plans

- Quality assurance versus quality control assessments

- Testing to ISO 21809 standards

- Full project lifecycle coverage

- Customized testing protocols

Field joint coating expertise

Field joint coating expertise

As field joint specialists, we understand that welded areas represent the most vulnerable points in your pipeline infrastructure. Our targeted testing focuses on validating that your field joint coatings—applied on offshore lay vessels during pipeline assembly—can withstand the unique challenges of subsea environments. We leverage our combined expertise in welding, non-destructive testing (NDT), and coatings to deliver truly comprehensive evaluations that address every aspect of field joint protection.

Cutting-edge equipment we use

Cutting-edge equipment we use

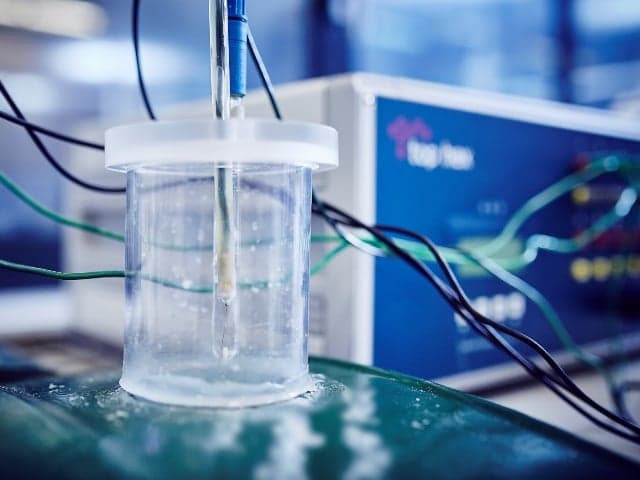

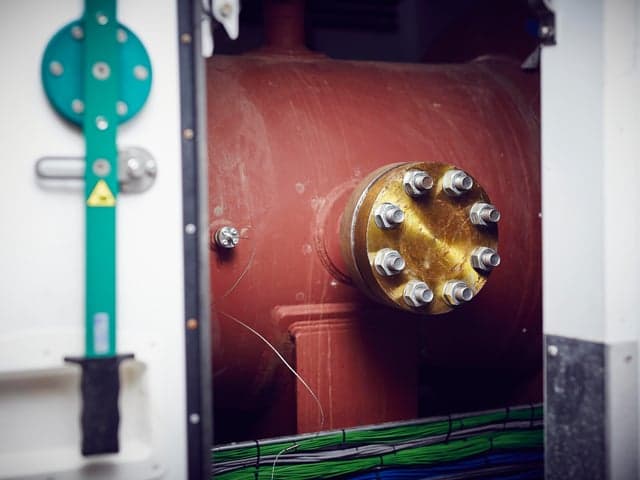

Element utilizes the latest equipment and technology solutions specifically designed for pipeline and field joint coating evaluation. Our advanced testing capabilities allow us to simulate the extreme environmental conditions your pipelines will face, from subsea pressure to temperature fluctuations. This technology-forward approach ensures all coating performance data accurately reflects real-world scenarios your assets will encounter throughout their operational life.

Standards we test to and materials we test

- ISO 21809 (Parts 1-3)

- International and National standards

Tape systems

- Hot-Applied Bituminous Tapes

- Cold-Applied Polymeric Tapes

- Petrolatum Tapes

- Wax Tapes

Polymer coatings

- Polyethylenes (PE)

- Polypropylenes (PP)

- Heat-Shrinkable Sleeves

- Flame-Sprayed Polyolefins

Epoxy coatings

- Fusion-Bonded Epoxies (FBE)

- Liquid Epoxies

Advanced systems

- Polyurethanes (PUR)

- Three-Layer Polyethylene Coatings (3LPE)

- Three-Layer Polypropylene Coatings (3LPP)

- Three-Layer Polyolefin Coatings (3LPO)

Your Challenges, Our Solutions

Corrosion protection for extreme environments

Field joint integrity assurance

Standards compliance made simple

Complete project lifecycle validation

Why Choose Element

Industry-leading expertise

Proven track record

Complete testing suite

Real-world simulation

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.

Coating and Paint Adhesion Testing

Adhesion testing services for paints and coatings to evaluate performance, meet ASTM standards, and address coating failures with expert analysis and actionable insights.