Mechanical Testing of Composites

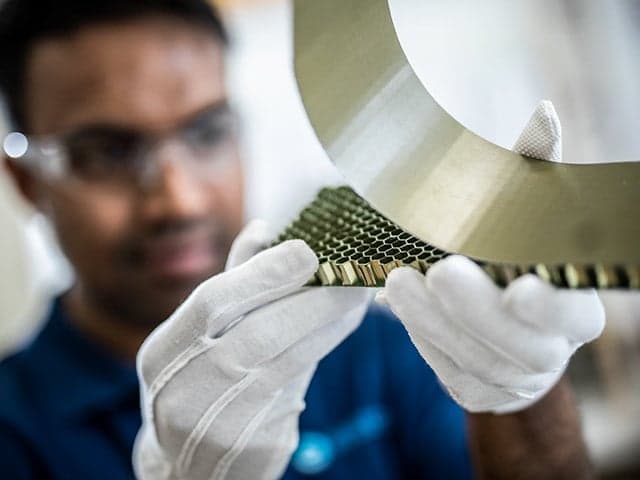

Unlock the full potential of your composites with fast, hands-on mechanical testing. Our experts guide you at every stage – from R&D through production and failure analysis – tailoring solutions for tensile, shear, compression, and fatigue. When no single standard applies, we develop custom methods to ensure accurate, reliable data. Elevate performance with Element’s comprehensive composite materials testing.

What is Mechanical Testing of Composites at Element?

Mechanical testing of composites evaluates strength, durability, and performance characteristics of lightweight, high-strength materials. At Element, we offer comprehensive testing services to validate material properties in R&D, ongoing production, or failure investigations—ensuring your composites meet demanding specs. Because composite testing often spans multiple methods (tensile, shear, compression, fatigue), we tailor solutions to each application’s needs, even when a standard method may not exist for certain compression tests.

What Can Element Offer You For Mechanical Testing of Composites?

Materials we test

Materials we test

From aerospace to automotive structures, we cover a broad range of composite materials—simple coupons to complex assemblies. By focusing on mechanical behavior, we help confirm that each composite retains its lightweight advantage and robust mechanical properties, essential for modern industries seeking stronger, more efficient designs.

- Polymer matrix composites (PMCs)

- Ceramic matrix composites (CMCs)

- Composite sandwich structures

- Laminated materials

- Fiber-reinforced composites (carbon, glass, aramid, etc.)

Key Tests Offered

Key Tests Offered

Element provides a full suite of mechanical tests to characterize composites. We work with you to determine the ideal approach—recognizing, for instance, that “no single standard” exists for certain compressive tests, requiring customized solutions.

- Compression testing (various industry-standard & custom methods)

- Fatigue testing (long-term performance)

- Open hole compression & tensile testing (practical design insights)

- Sandwich structure tests (flatwise tensile, core shear, bending)

Methods And Solutions Offered

Methods And Solutions Offered

Our experts employ industry-standard and custom methodologies to meet your exact testing requirements. Whether for R&D (early material selection), production QA (batch consistency), or failure analysis (root cause investigations), we tailor each approach. We also guide you in selecting the most suitable test method, especially for compression strength where recognized standards can be limited or incomplete.

- Customized programs for unique composite architectures

- R&D support from initial selection to final validation

- Quality control to ensure consistent production runs

- Failure analysis for root cause and prevention

- Complete characterization for mechanical properties under varied conditions

- Regulatory compliance with relevant industry or OEM standards

Expert consultation and custom solutions

Expert consultation and custom solutions

Beyond standard test methods, we collaborate closely with your engineering teams. Some composite materials or assemblies require bespoke test protocols. Our hands-on technical guidance ensures you get the precise data you need, even for novel composites or advanced manufacturing processes.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

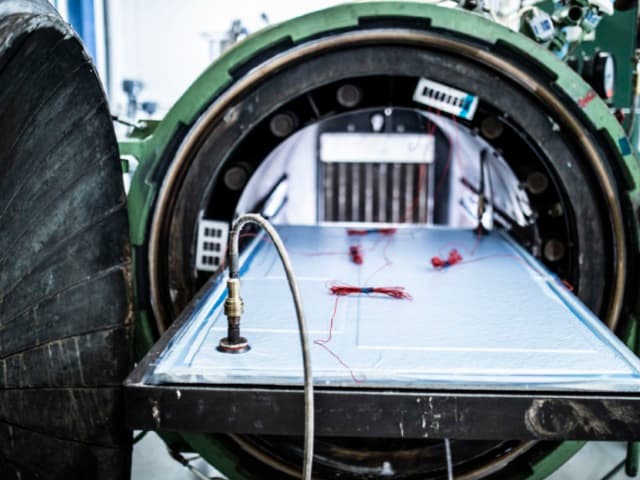

Our labs feature specialized load frames, environmental chambers, and high-precision measurement systems designed specifically for composite materials testing. We can replicate operating environments (e.g., temperature, humidity) to gauge performance under real-world conditions.

- Load frames for precise force control

- Custom fixtures for non-standard sample geometries

- Environmental chambers (temperature/humidity)

- Data acquisition for accurate measurements

- High-resolution imaging for failure analysis

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

- ASTM Specifications (e.g., ASTM D3039).

- We also address industry-specific or OEM standards.(Note: compression methods can vary due to no single universal standard in some cases.)

Polymer matrix composites (PMCs)

- Carbon fiber reinforced polymers

- Glass fiber reinforced polymers

- Aramid fiber composites

Composite sandwich structures

- Sandwich panels

- Core materials

Ceramic matrix composites (CMCs)

- Aerospace-grade ceramic composites

Your Challenges, Our Solutions

Clearly understanding complex properties

Quality consistency throughout production

Correctly applying industry standards expertly applied

Cost-effective, timely performance validation with confidence

Why Choose Element

Composite-specific testing expertise

Comprehensive test method selection

Custom testing program development

Industry standard compliance

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.