Automotive Dynamometer Testing Services

Transform your vehicle testing process with comprehensive automotive dynamometer testing services from the preferred partner of leading US manufacturers. Working with Element, you’ll receive clear, actionable, accurate data and faster time-to-market with industry-leading capabilities (15,000 RPM, 6,000 ft-lb torque). From complete drivetrain testing to specialized transmission testing solutions, including eAxles, we help you overcome complex testing challenges while meeting strict quality and regulatory requirements.

What is automotive dynamometer testing at Element?

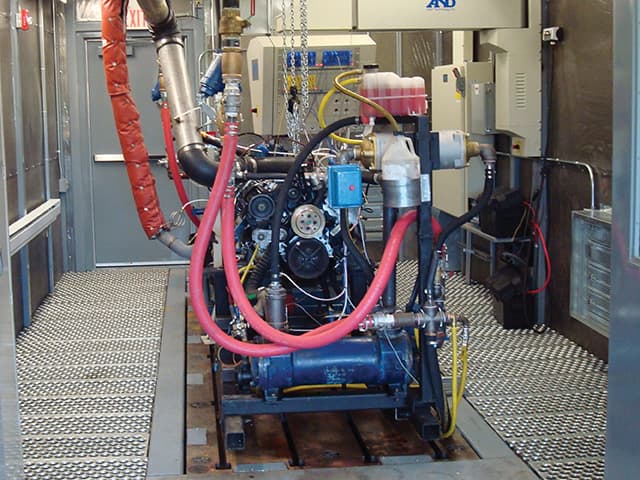

Automotive dynamometer testing evaluates the performance, durability, and quality of vehicle drivetrains under controlled conditions. At Element, we provide comprehensive testing services that simulate real-world conditions for complete vehicle systems and individual components, delivering accurate, actionable data to optimize your product development process.

Element offers comprehensive dyno testing as a standalone service or integrated within a complete vehicle testing program that includes mechanical analysis, fluid dynamics, electronics measurement, and environmental simulations.

What can Element offer you for automotive dynamometer testing?

Key tests offered

Key tests offered

Element is the preferred testing partner for the US’s largest vehicle manufacturers, offering truly comprehensive vehicle, system, and component testing services, including:

- Speed testing up to 15,000 RPM

- Torque measurement over 6,000 ft-lb

- Dynamic axial/radial load testing for geared hubs, spindles, and CV joints

- Environmental exposure testing including temperature variations, slurry, and salt spray

- Rotating machinery analysis for comprehensive performance assessment

- Automated control, monitoring and data acquisition with torque/speed profiles

- Automated transmission shift testing with back drive capability for transmissions, PTUs, gearboxes, axles, and driveshafts

Components and systems we test

Components and systems we test

We offer comprehensive drivetrain testing capabilities covering your entire powertrain system. Our expertise spans traditional combustion engine components to cutting-edge electric vehicle systems, ensuring thorough evaluation of every component in your vehicle's power delivery system.

Methods and solutions offered

Methods and solutions offered

We’ll be on your team for everything you need, including:

- Customized test fixtures and control equipment

- Automated control and monitoring systems

- Advanced data acquisition and analysis

- Environmental simulation capabilities

- Certification and pre-compliance management for national and international regulatory standards

- End-to-end testing programs

Cutting-edge equipment we use

Cutting-edge equipment we use

We can tailor our testing and setup to your needs, with equipment available to you including:

- High-capacity dynamometers

- Advanced data acquisition systems

- Environmental testing chambers

- Automated control systems

- Custom test fixtures

These advanced capabilities enable us to deliver precise performance data across your entire drivetrain system, helping you identify optimization opportunities, resolve potential issues early in development, and ensure your components meet all performance requirements before production—reducing costly redesigns and accelerating your time to market.

Which labs offer this service

Which labs offer this service

Our team operates from automotive hubs, providing convenient access to our expert capabilities. Find your nearest automotive lab on our Locations Page.

Components we test

Drivetrain Components:

- Transmissions

- Transaxles

- Transfer cases

- Rear axles

- U-joints

- Half-shafts

- Complete driveline systems

- eAxles

- Motors

- Alternators

- Bearings

Your Challenges, Our Solutions

Complex Testing Requirements

Time-to-Market Pressure

Quality and Compliance Demands

Technical Expertise Gaps

Why Choose Element

Unmatched Drivetrain Expertise

Customizable Testing Solutions

Advanced Real-World Simulation

Leading EV & Hybrid Testing

15,000RPM

6,000+ft-lb

100+Years

Frequently asked questions

What types of vehicle components can you test?

We test complete driveline systems including transmissions, transaxles, transfer cases, rear axles, U-joints, half-shafts, and specialized components like eAxles for electric vehicles.

Do you support electric and hybrid vehicle testing?

Yes, we have specialized equipment and expertise to assess performance and efficiency of electric and hybrid vehicle components, with particular focus on eAxle testing

What environmental conditions can you simulate?

Our dynamometers can simulate extreme temperatures, harsh environments, and various driving cycles. We can expose rotating components to temperature variations, slurry, and salt spray conditions.

How do you help manufacturers meet compliance requirements?

We provide comprehensive certification and pre-compliance management services for a wide range of national and international regulatory standards, supporting you through the entire approval process.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Automotive Testing Services

Accelerate automotive testing with Element’s end-to-end services. Ensure compliance, validate performance & reduce development time from components to full vehicles.

Full Vehicle Durability Testing

Element offers full vehicle durability testing, simulating real-world conditions in a lab to detect defects early, improve reliability, and support manufacturers in developing safer, long-lasting vehicles.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.