Rail Component Testing Services

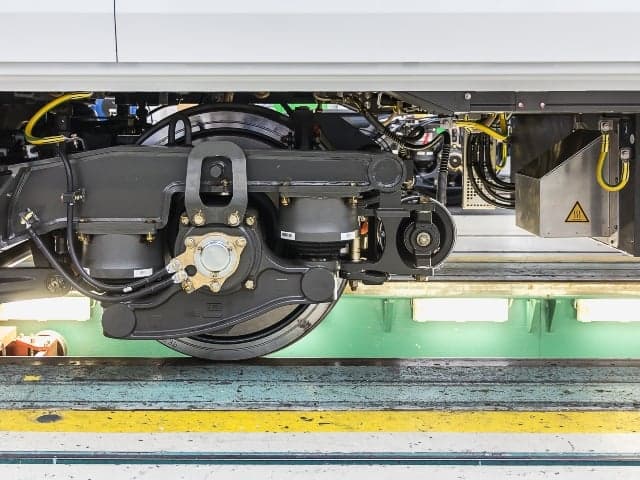

Ensure your rail components can endure the toughest conditions. You’ll get to market faster with confidence when you partner with Element experts. With over 75 years of railway expertise and a global network of state-of-the-art labs, Element delivers comprehensive material testing services – from fatigue testing and failure analysis to our exclusive AREMA Chapter 30 test 6 train simulator. We help you verify reliability, prevent failures and meet all regulatory requirements.

What is Rail Component Testing at Element?

Rail component testing is a comprehensive evaluation to ensure success under real-world operational conditions. This process examines mechanical properties like hardness, tensile strength, and impact resistance, as well as microstructural analysis.

At Element, we provide comprehensive assessments using advanced techniques like spectroscopy, scanning electron microscopy, and X-ray diffraction (XRD) to assess chemical composition and structural integrity. We also use non-destructive testing methods like ultrasonic testing and magnetic particle inspection to detect internal and surface flaws. By analyzing these properties alongside functional use, we help predict performance, durability, and safety while ensuring industry standards compliance.

What can Element offer you for Rail Component Testing Services?

Key Tests Offered

Key Tests Offered

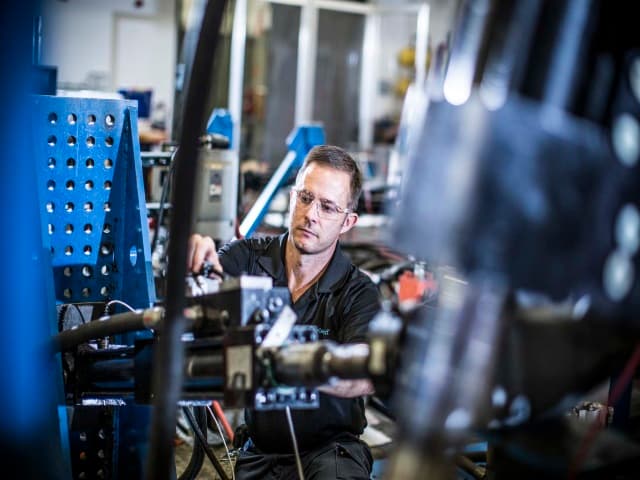

Element's rail component testing capabilities cover the full spectrum of evaluation needs, from basic mechanical property assessment to advanced microstructural analysis. Meet tight development schedules and regulatory deadlines by conducting multiple tests simultaneously. This capability at Element makes the process more efficient for your rail projects.

- Calibration testing

- Composite and plastic testing

- Hardness testing

- Impact testing

- Longitudinal restraint testing

- Repeated load testing

- Structural testing

- Tensile testing

- Vertical load testing

- Vertical restraint testing

Components And Materials We Test

Components And Materials We Test

We test a comprehensive range of rail components. Whatever your needs, our experts can design appropriate testing protocols to evaluate mechanical properties, structural integrity, and long-term performance under simulated real-world conditions.

- Ties and sleepers

- Fastening systems and clips

- Seat assemblies

- Steel rail components

- Composite and plastic components

Methods And Solutions Offered

Methods And Solutions Offered

Element offers an industry-leading range of testing methodologies designed specifically for rail component challenges:

- Advanced numerical modelling

- Clean steel evaluation (impurity detection)

- Erosion inspection

- Finite element analysis simulation

- Full spectrum chemical composition analysis

- Macrostructure analysis (defect detection)

- Magnetic particle inspection

- Martensite evaluation (per weld)

- Metallography Microstructure analysis

- Particle analysis

- Residual stress measurement

- Scanning electron microscopy (SEM)

- Spectroscopy

- Tribology and wear pattern analysis

Supporting sustainability through advanced testing

Our rail component testing services directly support your sustainability objectives by extending the lifespan of your rail infrastructure. Through detailed analysis of rail materials, we identify weaknesses and improvement areas that reduce material waste and minimize unnecessary replacements and repairs. This approach not only aligns with corporate social responsibility goals but delivers tangible cost savings by optimizing resource utilization and reducing maintenance requirements.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our state-of-the-art laboratories feature unique frames and specialized equipment unavailable elsewhere in the industry. With our exclusive AREMA Chapter 30 test 6 train simulator, your test programs will replicate real-world operating conditions with unmatched accuracy.

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from rail, transportation and manufacturing hubs across the world, providing global access to our expert capabilities. Find your nearest lab on our Locations Page.

Standards we test to and materials we test

- AREMA Chapter 30 standards

- Global rail industry regulations and standards

Rail components

- Welded rail joints and connections

- Mechanical fasteners and assemblies

- Electronic control systems

- Interior fixtures and fittings

- Safety-critical components

Materials

- Carbon steel

- Alloy steel

- Composite materials

- Plastics

Your Challenges, Our Solutions

Safety and reliability

Risk of costly failures

Regulatory complexity

Development efficiency

Why Choose Element

Exclusive Testing Capabilities

Global reach, local expertise

Comprehensive single-source testing

Proven industry experience

But don't just take our word for it

See what others want to say about partnering with Element

Frequently asked questions

What is railway steel made from?

The main component of railway steel is usually carbon steel, which is an alloy of iron and carbon – combined with other elements to enhance the strength, hardness, and corrosion resistance (e.g manganese). This allows the steel to be strong enough to withstand heavy loads, deal with wear, and remain strong in a range of environmental conditions.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Residual Stress Measurement

Our experts offer a variety of techniques for residual stress measurement, including XRD and RSM, strain gaging, and Barkhausen Noise Analysis.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Rail Testing Services

Element provides comprehensive rail testing services, ensuring materials, infrastructure, and rolling stock meet safety and compliance standards with expert analysis and advanced laboratory technology.

EN 50121 Railway EMC Standards

Element provides EMC testing and certification services for railway components, helping manufacturers meet EN 50121 standards for compliance, reliability, and safety in real-world rail environments.

Rail Fire Testing Services

Ensure rail fire safety with expert testing and certification. Our team helps you navigate standards to protect passengers and assets effectively. Learn More.

AREMA Chapter 30 Rail Simulation Programs

Element's AREMA Chapter 30 rail simulation programs replicate real-world conditions to assess failures, material wear, and durability. We help rail organizations improve performance, extend product lifespan, and meet compliance standards.

Rail Infrastructure Services

Element provides accredited rail infrastructure testing and inspection services to improve material performance, prevent failures, and maintain compliance with industry standards.

Rail Inspection Services: Rolling Stock

Element provides accredited rail inspection services for rolling stock, offering expert testing to assess safety, durability, and compliance with industry regulations.

Railroad Failure Analysis

Expert railroad failure analysis to identify root causes, improve safety, and extend component lifespan. Advanced testing of rail components ensures informed decisions and reliable performance.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

- Residual Stress Measurement

- Stress Rupture and Creep Testing

- Fatigue Testing Services

- Rail Testing Services

- EN 50121 Railway EMC Standards

- Rail Fire Testing Services

- AREMA Chapter 30 Rail Simulation Programs

- Rail Infrastructure Services

- Rail Inspection Services: Rolling Stock

- Railroad Failure Analysis

- Durability Testing of Trailer Hitches