AREMA Chapter 30 Rail Simulation Programs

One trusted partner gives you access to North America’s most advanced rail simulation, helping you prevent costly failures and extend component life. Our AREMA Chapter 30 Rail Simulation Programs recreate real-world conditions with unmatched precision, giving you accurate insights into performance and helping you develop more durable railroad products that withstand the toughest conditions - all with end-to-end convenience.

What is AREMA Chapter 30 Rail Simulation Testing at Element?

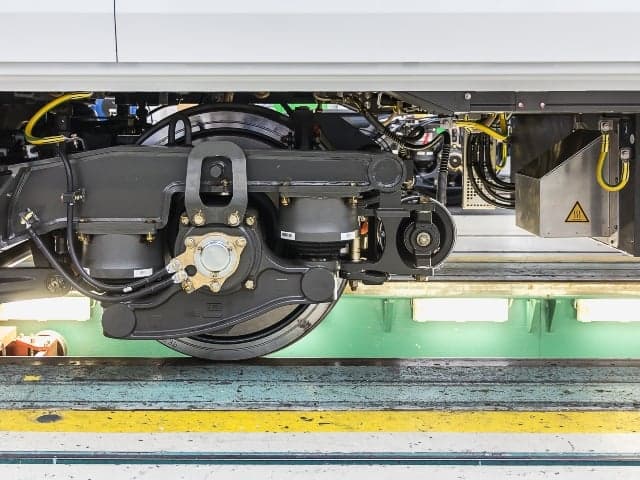

AREMA Chapter 30 Rail Simulation testing recreates the mechanical forces and environmental conditions associated with heavy train use to evaluate rail component performance. At Element, we custom-build highly realistic test frames that incorporate both physical and environmental factors to measure rolling fatigue and provide the most accurate testing results available. Our comprehensive programs can test everything from concrete ties to fully assembled rails and all components in between.

What Can Element Offer You For AREMA Chapter 30 Rail Simulation Programs?

Key tests offered

Key tests offered

Element's rail simulation testing capabilities provide detailed insights into through specialized testing protocols that identify potential issues before they occur in the field.

- AREMA Chapter 30 Section 4.9 Test 6 simulations

- Rail seat abrasion testing

- Weld integrity evaluation

- Tensile strength measurement

- Fatigue and compression testing

- Mechanical force simulation

- Wood, concrete and composites testing

Components and materials we test

Components and materials we test

We test the full spectrum of critical railroad infrastructure components to ensure performance under real-world conditions. Each component is subjected to realistic mechanical forces and environmental stressors to accurately predict field performance and identify potential failure points.

- Railroad ties (concrete, wood, and composite)

- Rail fasteners and anchoring systems

- Fully assembled rail sections

- Rail seats and connections

- Welds and joint assemblies

Methods and solutions offered

Methods and solutions offered

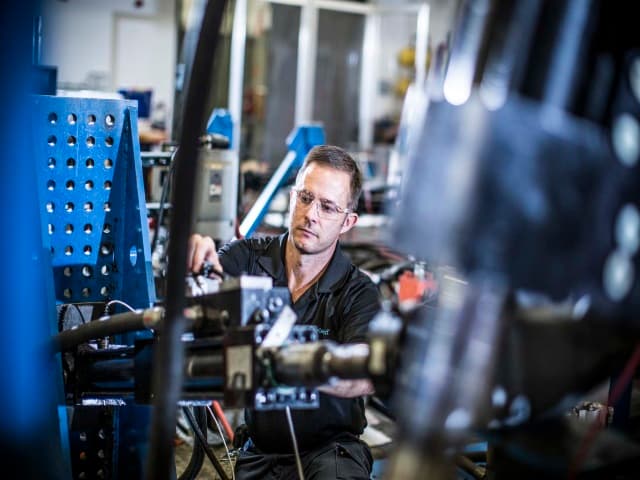

We create custom test programs that replicate your specific operating conditions, identifying potential issues before they impact your operations or safety record. By combining mechanical, metallurgical, and weld testing methods with AREMA Chapter 30 guidelines, we provide solutions that answer the most challenging questions in the railroad industry.

- Custom-built realistic test frames

- Environmental conditioning from -40°F to 140°F

- Humidity and ASTM B117 salt spray testing

- Sand and dust ingress evaluation

- Contaminant and corrosion analysis

- Root cause failure analysis

Advanced failure analysis simulations

When rail components fail in the field, both safety and finances are at risk. Our simulation programs identify potential failure modes by replicating real-world conditions with exceptional accuracy. We provide comprehensive answers when you need them most, helping you prevent future costly failures and extend component lifespan.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities feature specialized equipment that precisely simulates the unique stresses of railroad applications. With custom-built test frames that recreate actual mechanical forces and environmental chambers that replicate extreme conditions, we deliver the most accurate and reliable test results possible for your rail components.

- Custom-built simulation frames replicating mechanical forces

- Environmental chambers for temperature (-40°F to 140°F) and humidity testing

- ASTM B117 salt spray equipment

- Metallurgical testing and inspection equipment

- Microscopic inspection tools

- Tensile strength testing apparatus

- Specialized rail seat abrasion testing equipment

Which labs offer this service

Which labs offer this service

Our team operates from rail, transportation and manufacturing hubs across the world, providing global access to our expert capabilities. Find your nearest lab on our Locations Page.

Standards we test to and components we test

- AREMA Chapter 30 Section 4.9 Test 6

- AREMA Chapter 30 weld integrity test

- ASTM B117 salt spray

Railroad components

- Railroad ties (concrete, wood, and composite)

- Rail fasteners and anchors

- Fully assembled rails

- Rail seats

- Welds and joints

Materials

- Concrete

- Wood

- Composite materials

- Metal fasteners

- Steel rail components

Your Challenges, Our Solutions

Preventing costly field failures

Extending component lifespan

Meeting stringent industry standards

Withstanding extreme environments

Why Choose Element

Complete simulation capabilities

Comprehensive environmental testing

One-stop testing solution

Most unique rail capabilities

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Rail Testing Services

Element provides comprehensive rail testing services, ensuring materials, infrastructure, and rolling stock meet safety and compliance standards with expert analysis and advanced laboratory technology.

EN 50121 Railway EMC Standards

Element provides EMC testing and certification services for railway components, helping manufacturers meet EN 50121 standards for compliance, reliability, and safety in real-world rail environments.

Rail Fire Testing Services

Ensure rail fire safety with expert testing and certification. Our team helps you navigate standards to protect passengers and assets effectively. Learn More.

Bending Stress and Flexural Strength Rail Testing

Element provides bending stress and fatigue testing for railroads, helping engineers validate materials, improve weld integrity, and prevent failures with advanced flexural and cyclic fatigue analysis.

Rail Component Testing Services

Element provides advanced rail component testing to assess durability, detect defects, and ensure compliance. Using state-of-the-art labs and industry expertise, we help optimize safety, performance, and reliability.

Rail Infrastructure Services

Element provides accredited rail infrastructure testing and inspection services to improve material performance, prevent failures, and maintain compliance with industry standards.

Rail Inspection Services: Rolling Stock

Element provides accredited rail inspection services for rolling stock, offering expert testing to assess safety, durability, and compliance with industry regulations.

Railroad Failure Analysis

Expert railroad failure analysis to identify root causes, improve safety, and extend component lifespan. Advanced testing of rail components ensures informed decisions and reliable performance.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.