Bending Stress and Flexural Strength Rail Testing

Your rail infrastructure demands materials that withstand immense pressure while maintaining flexibility. Our comprehensive bending stress and flexural strength rail testing validates weld integrity, prevents failures, and accurately simulates real-world conditions. By adding mechanical testing analysis to your program, our experienced experts provide end-to-end solutions that give you confidence in your rail components' performance and longevity.

What is Bending Stress and Flexural Strength Rail Testing at Element?

Bending stress and flexural strength testing evaluates how rail materials and components respond to applied forces. One key test is slow bend testing, which validates concrete tie strength and rail weld integrity. Another is cyclic fatigue testing, which demonstrates the ability of rail and integrated fastening systems to withstand repeated loads. At Element, we perform comprehensive rail testing for both slow bend and dynamic and static cyclic fatigue, helping you select materials with optimal strength and flexibility characteristics for the next generation of rail technology.

What Can Element Offer You For Bending Stress and Flexural Strength Rail Testing?

Key tests offered

Key tests offered

Element's comprehensive suite of tests evaluates every aspect of your rail components' performance under stress.

- Slow bend testing (4-point flexural)

- Static and dynamic fatigue testing

- Cyclic fatigue testing

- Rolling fatigue simulation

- Weld integrity verification

- Surface defect analysis

Components and materials we test

Components and materials we test

We test critical rail infrastructure components that face the most demanding conditions on your track. Our expertise helps you validate every component in your rail system, ensuring each meets the rigorous demands of freight and passenger service.

- Rail welds and welding points

- Complete rail sections up to 5 ft (1.52 m)

- Concrete ties

- Integrated fastening systems

- Fully assembled sections of railroad

Methods and solutions offered

Methods and solutions offered

We custom-design testing programs based on your specific rail materials and components, replicating the actual stresses they'll encounter in the field. Our approach combines rigorous mechanical testing with advanced metallurgical analysis, giving you complete understanding of performance characteristics, structural limits, and potential failure points before deployment.

- Bending stress application up to 750 kips

- AREMA Chapter 30 compliant testing

- Post-test metallurgical analysis

- Crack and surface defect examination

- Root cause failure determination

- Comprehensive material characterization

Comprehensive failure analysis capabilities

When testing reveals potential weaknesses in your rail components, our integrated approach means we can immediately perform multiple industry-specific metallurgical tests to determine root causes. This seamless transition from mechanical testing to advanced analysis helps you quickly identify and address issues, saving valuable development time and resources.

Cutting-edge equipment we use

Cutting-edge equipment we use

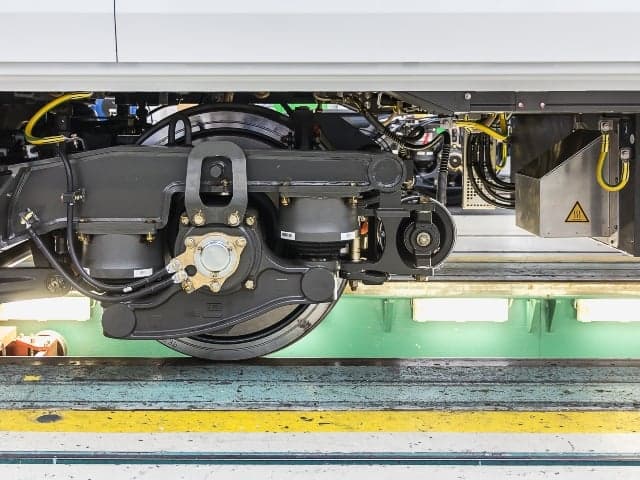

Our state-of-the-art testing equipment delivers the most accurate simulations available in the rail industry. Our one-of-a-kind train simulator and specialized test frames allow us to recreate the exact conditions your rail components will face in service, providing reliable data that supports your material selection and design validation processes.

- One-of-a-kind train simulator specifically designed for AREMA Chapter 30 section 4.9 sub-section 2.7 Test 6 rolling fatigue simulation

- Specialized test frames for static and dynamic testing up to 120 kips

- 4-point flexural testing equipment

- Advanced metallurgical laboratory equipment

- Industry-specific testing apparatus

Our train simulator provides both static and dynamic testing up to 120 kips. This specialized equipment allows us to accurately simulate rolling fatigue on fully assembled rail sections, giving you reliable performance data that supports critical material selection processes for major railroad companies.

Which labs offer this service

Which labs offer this service

Our team operates from rail, transportation and manufacturing hubs across the world, providing global access to our expert capabilities. Find your nearest lab on our Locations Page

Standards we test to and materials we test

- AREMA Chapter 30 section 4.9 sub-section 2.7 Test 6

Rail infrastructure

- Rail welds

- 5 ft (1.52 m) rail sections

- Complete rail segments

Fastening systems

- Concrete ties

- Rail fasteners

- Integrated fastening assemblies

- Complete assembled rail sections

Your Challenges, Our Solutions

Preventing costly rail failures

Validating performance under repeated loads

Confirming material selection decisions

Ensuring fastening system durability

Why Choose Element

Industry-specific expertise

Comprehensive testing solutions

Advanced simulation capabilities

Customer-centric approach

750kips

120kips

1of a kind

Frequently asked questions

How is slow bend testing performed for rail weld integrity?

Using 5 ft (1.52 m) sections of rail, we focus bending stress on the center of the weld up to 750 kips. This 4-point flexural testing is critical for determining weld integrity. After testing, if the weld hasn't completely sheared, we examine the rail for cracks and surface defects, and if needed, immediately perform multiple industry-specific metallurgical tests to determine the root cause of any failures.

What makes Element's fatigue testing capabilities unique?

Our fatigue testing uses a one-of-a-kind train simulator specifically designed for AREMA Chapter 30 section 4.9 sub-section 2.7 Test 6. This allows us to test fully assembled sections of railroads for rolling fatigue simulation with static and dynamic testing up to 120 kips. Our specialized test frames can test virtually any rail component, from individual rails to complete fastening systems, providing the most accurate simulations available in the industry.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Residual Stress Measurement

Our experts offer a variety of techniques for residual stress measurement, including XRD and RSM, strain gaging, and Barkhausen Noise Analysis.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Rail Testing Services

Element provides comprehensive rail testing services, ensuring materials, infrastructure, and rolling stock meet safety and compliance standards with expert analysis and advanced laboratory technology.

EN 50121 Railway EMC Standards

Element provides EMC testing and certification services for railway components, helping manufacturers meet EN 50121 standards for compliance, reliability, and safety in real-world rail environments.

Rail Fire Testing Services

Ensure rail fire safety with expert testing and certification. Our team helps you navigate standards to protect passengers and assets effectively. Learn More.

AREMA Chapter 30 Rail Simulation Programs

Element's AREMA Chapter 30 rail simulation programs replicate real-world conditions to assess failures, material wear, and durability. We help rail organizations improve performance, extend product lifespan, and meet compliance standards.

Rail Component Testing Services

Element provides advanced rail component testing to assess durability, detect defects, and ensure compliance. Using state-of-the-art labs and industry expertise, we help optimize safety, performance, and reliability.

Rail Infrastructure Services

Element provides accredited rail infrastructure testing and inspection services to improve material performance, prevent failures, and maintain compliance with industry standards.

Rail Inspection Services: Rolling Stock

Element provides accredited rail inspection services for rolling stock, offering expert testing to assess safety, durability, and compliance with industry regulations.

Railroad Failure Analysis

Expert railroad failure analysis to identify root causes, improve safety, and extend component lifespan. Advanced testing of rail components ensures informed decisions and reliable performance.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

- Residual Stress Measurement

- Stress Rupture and Creep Testing

- Fatigue Testing Services

- Rail Testing Services

- EN 50121 Railway EMC Standards

- Rail Fire Testing Services

- AREMA Chapter 30 Rail Simulation Programs

- Rail Component Testing Services

- Rail Infrastructure Services

- Rail Inspection Services: Rolling Stock

- Railroad Failure Analysis

- Durability Testing of Trailer Hitches