Testing Environmental Effects on Composites

Predict how your composite materials will perform when exposed to moisture, thermal cycling, fluids, and UV radiation in real-world environments. Our accelerated testing simulates up to 25 years of service life in weeks, with end-to-end testing from exposure to property evaluation. Our technical experts guide you through compliance requirements, preventing costly failures.

What is Environmental Effects Testing on Composites at Element?

Testing environmental effects on composites evaluates how composite materials perform when exposed to environmental factors over time. With the increasing demand for composites due to their high strength-to-weight ratio, corrosion resistance, and impressive fatigue performance, understanding environmental impacts is crucial. At Element, we simulate real-world conditions including moisture, thermal cycling, fluid exposure, and UV radiation to predict your material's performance throughout its lifecycle. Our accelerated aging techniques compress years of environmental exposure into weeks, providing crucial data for material selection and qualification.

What Can Element Offer You For Testing Environmental Effects on Composites?

Key tests offered

Key tests offered

Our comprehensive testing suite evaluates how environmental factors affect your composite's mechanical and physical properties. We accelerate aging processes to predict long-term performance, identifying potential degradation mechanisms before they become costly field issues. Our moisture conditioning follows ASTM D5229 methodology with precision monitoring of representative travelers to determine moisture equilibrium, while our thermal cycling simulates temperature fluctuations that your materials will face in service, helping you avoid polymer matrix microcracking and mechanical property loss.

- Moisture conditioning (ASTM D5229) with representative traveler monitoring

- Thermal cycling and thermal shock testing to identify microcracking risks

- Fluid exposure testing with single-phase or multi-phase fluids

- Accelerated aging through controlled temperature and pressure

- Post-exposure mechanical and physical testing (tensile, compression, shear, flexure)

Materials we test

Materials we test

From polymer-based composites used in aerospace to composites in Oil and Gas applications, we test materials designed for the most demanding environments. Our services cover composites exposed to moisture, thermal cycling, fluid contact, and UV radiation—precisely simulating your product's operating conditions to validate performance. With expertise in both load-bearing and non-load bearing structures, we help you understand how environmental factors will impact your specific composite applications.

- Polymer-based composites that absorb moisture from the air in regular service

- Composites for Oil and Gas applications in deep water corrosive environments

- Aircraft load-bearing composite structures experiencing thermal cycling

- Aircraft non-load bearing composite structures exposed to various fluids

- Composites requiring long-term performance prediction in challenging environments

Methods and solutions offered

Methods and solutions offered

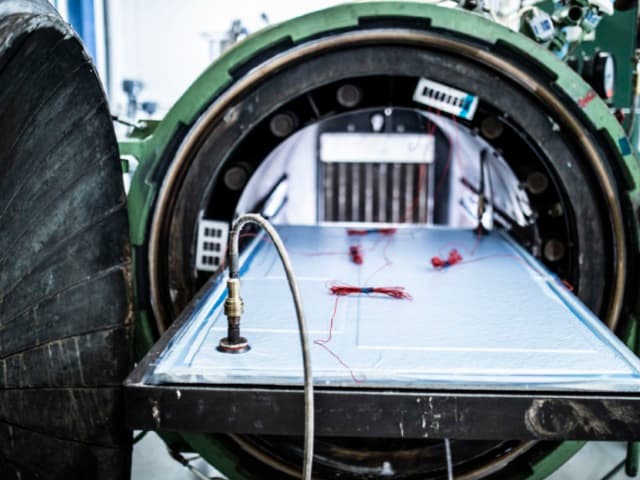

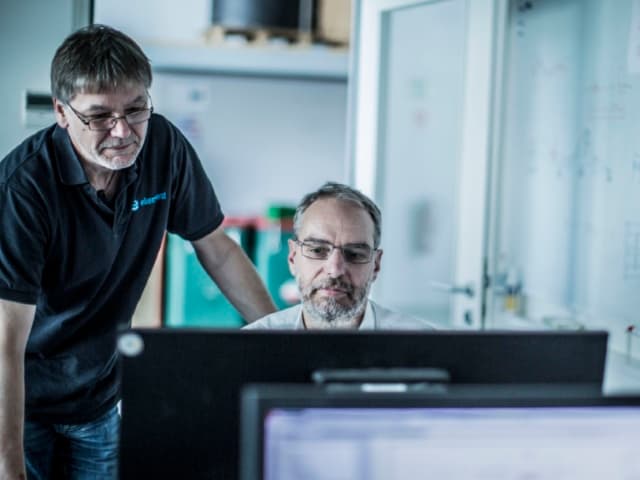

We customize testing protocols to match your specific service environment, compressing decades of exposure into weeks of laboratory testing. By carefully selecting pressure, temperature, and exposure conditions, we can simulate up to 25 years of service life. Our approach includes exposing composite samples to fluids in pressure vessels at defined conditions, then increasing temperature and pressure to accelerate physical and chemical aging. After exposure, we quantify environmental effects through comprehensive mechanical and physical property testing including tensile, compression, shear, flexure, DSC, TGA, and thermal conductivity assessment.

- Environmental simulation in humidity chambers with precise control

- Thermal shock and cycling chambers to identify microcracking potential

- Service fluid exposure in pressure vessels at controlled conditions

- Accelerated physical and chemical aging through temperature and pressure control

- Comprehensive post-exposure property evaluation and degradation assessment

Extreme environment simulation expertise

Our specialized capabilities include testing in the most demanding environmental conditions that your composites might face. With experience running exposure tests for any type of liquid or gas required by our clients, including pure H2S, supercritical CO2, and seawater, we help you validate material performance in even the most aggressive service environments. We understand that polymer-based composites can experience plasticization of polymer chains from moisture absorption, resulting in lower glass transition temperature (Tg) and degraded mechanical properties. Our testing identifies these specific mechanisms, ensuring your materials maintain their integrity throughout their service life in challenging conditions.

- Testing with aggressive fluids including pure H2S and supercritical CO2

- Simulation of deep-water corrosive environments for oil and gas applications

- Evaluation of polymer plasticization and Tg reduction from moisture exposure

- Identification of microcracking failure mechanisms from thermal cycling

- Quantification of property degradation from long-term environmental exposure

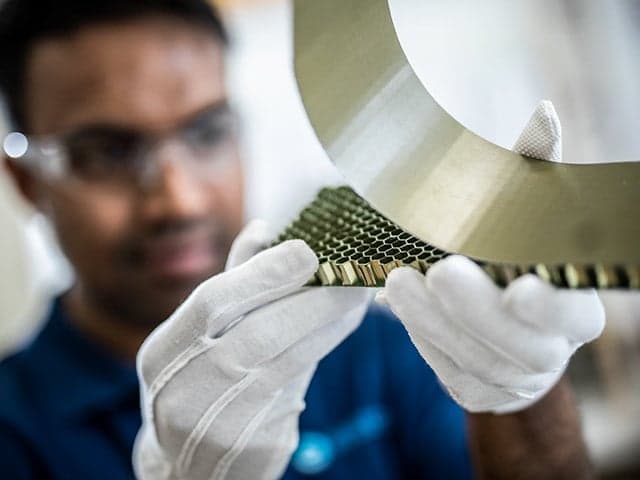

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are equipped with specialized environmental chambers, pressure vessels, and precision testing equipment. This allows us to create exact replicas of your product's operating environment—whether that's deep-water corrosive settings or aircraft service conditions—while maintaining precise control over all variables. Our thermal shock and thermal cycling chambers simulate end-use temperature fluctuations, while our pressure vessels allow exposure to any fluid your materials might encounter in service. Sophisticated analytical equipment enables precise measurement of property changes after exposure.

- Humidity chambers for moisture conditioning with precise temperature and humidity control

- Thermal shock and cycling chambers for temperature fluctuation simulation

- Pressure vessels for fluid exposure at controlled temperature and pressure

- Advanced mechanical testing equipment for post-exposure property evaluation

- Analytical instruments (DSC, TGA, thermal conductivity) for detailed material characterization

Which labs offer this service

Which labs offer this service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

- ASTM D5229 (Moisture Absorption Properties and Equilibrium Conditioning)

- Customer-specific test standards and industry requirements

- Internal validated protocols for accelerated aging and property evaluation

Polymer-based composites

- Polymer matrix composites exposed to moisture absorption

- Polymer composites subject to thermal cycling and temperature fluctuations

- Polymer-based materials requiring fluid exposure testing

- Composites requiring UV and environmental weathering assessment

- Materials susceptible to polymer chain plasticization and Tg reduction

Application-specific composites

- Oil and Gas industry composites for deep water corrosive environments

- Aircraft load-bearing composite structures experiencing thermal cycling

- Aircraft non-load bearing composite structures exposed to various fluids

- Composites requiring long-term performance prediction (up to 25 years)

- Composites exposed to aggressive service fluids like H2S and supercritical CO2

Your Challenges, Our Solutions

Real-world performance insight

Timely long-term reliability verification

Selecting materials for long-term integrity

Compliance requirements complexity

Why Choose Element

Environmental simulation accuracy

Accelerated aging precision

Comprehensive post-exposure analysis

Specialized fluid compatibility expertise

25+years

190+years

8,500+engaged experts

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.