Pressure Testing Services

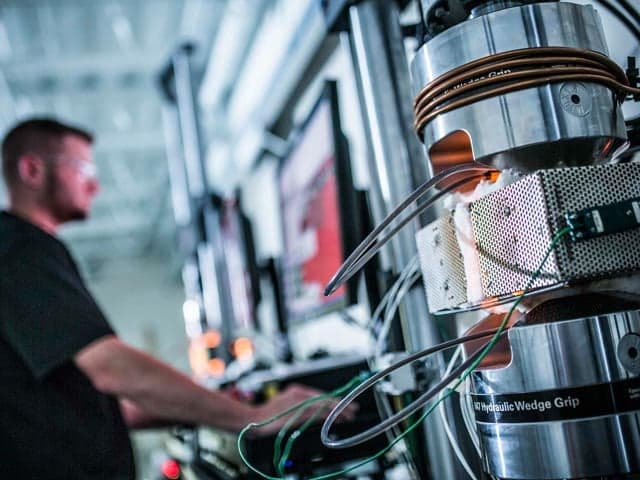

Make sure your equipment won't fail under pressure. Element's comprehensive pressure testing services help prevent catastrophic failures and ensure long-term reliability. From hydrostatic pressure testing to advanced cyclic pressure testing up to 200,000 PSI/sec, we verify your products to meet safety standards and perform reliably throughout their service life. Our expert’s will guide you to establish safe operating parameters for total peace of mind.

What is Pressure Testing at Element?

Pressure testing evaluates the integrity of vessels, components, and systems under controlled pressure conditions. At Element, we provide both static and dynamic testing using hydraulic and pneumatic methods, with the ability to condition fluids to extreme temperatures. Our comprehensive testing validates pressure ratings and ensures product reliability across your entire system.

What Can Element Offer You For Pressure Testing?

Components and materials we test

Components and materials we test

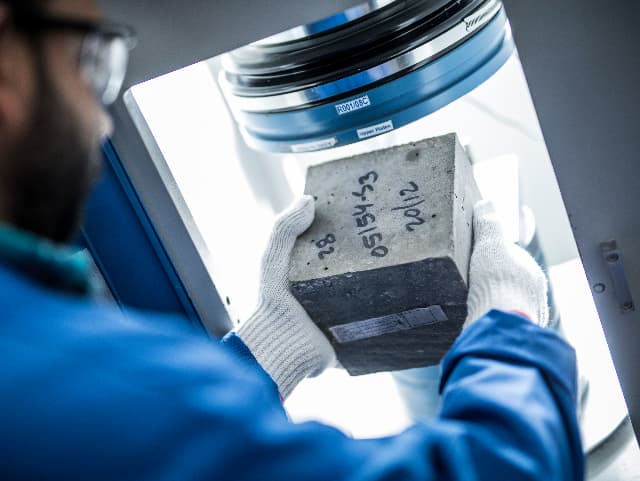

We test a comprehensive range of pressure-bearing components, from individual parts to complete systems. Our expertise covers pressure vessels, pipes, tubing, fuel assemblies, boiler components, fuel tanks, and ventilation systems. We can evaluate virtually any product requiring pressure certification.

Key tests offered

Key tests offered

- Hydrostatic pressure testing for material integrity

- Pneumatic pressure testing for leak detection

- Cyclic pressure testing for fatigue evaluation

- Ultimate pressure testing for maximum tolerance

- Burst pressure testing for failure point analysis

- Proof pressure testing for operational validation

- Mechanical and structural pressure testing to evaluate environmental forces on structures and materials

- Depth and submerge testing for underwater applications

Methods and solutions offered

Methods and solutions offered

Our testing methods adapt to your specific needs. We offer pressure conditioning at extreme temperatures, rapid pressure cycling up to 200,000 PSI per second, and comprehensive system evaluation. All testing aligns with industry standards while accommodating custom requirements

Which labs offer this service

Which labs offer this service

Our 9,000-strong team operates from product qualification testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest product qualification testing hub is on our Locations Page.

Specialized industry solutions

Specialized industry solutions

We offer dedicated testing solutions for specific sectors, including specialized mechanical and structural pressure testing for building products. Our experts evaluate environmental forces through comprehensive load testing programs tailored to construction industry requirements.

Standards we meet and the materials we test

Aerospace Recommended Practice

- ARP 1383, Figure 1,2 & 3

American Society of Mechanical Engineers

- ASME V SA450; ASME V SA530

American Society for Testing & Materials

- ASTM D751; ASTM E1003; ASTM F1387

Military Standards

- MIL-DTL-7905

Various Customer Specifications

- Breeze Eastern ECO 28183; Amerex DTP ES-2010-1052; Goodrich ED/3424/55QS; Goodrich ED/3564/09QS; Honeywell SOW-WPI-PCE

- Pressure vessels and pipes

- Tubing and fuel assemblies

- Boiler components

- Fuel tanks

- Sealing systems and ductwork

Your Challenges, Our Solutions

Preventing Catastrophic Failures

Ensuring Long-term Reliability

Meeting Industry Standards

System Integrity Verification

Why Choose Element

Complete Testing Solutions

Advanced Technical Capabilities

Custom Testing Programs

Global Testing Network

Frequently asked questions

Do you offer specialized pressure testing for building products?

Yes. Our building products experts provide specialized mechanical and structural pressure testing to evaluate environmental forces. This includes Racking Shear, Axial Load, Transverse Load, Diaphragmatic and Long-Term Transverse Load testing.

What's the difference between hydrostatic and pneumatic pressure testing?

Hydrostatic testing uses liquid to verify pressure ratings and material integrity, while pneumatic testing uses air pressure to detect leaks in sealing systems and ventilation components.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Product Qualification Testing (PQT) Services

Element’s product qualification testing verifies safety, compliance, and performance, helping businesses reduce risk, accelerate market entry, and meet global standards with expert guidance and accredited testing services.

Infrastructure Testing Services

Element provides industry-leading infrastructure testing services, helping construction and civil engineering projects improve safety, meet regulations, and optimize performance with expert analysis and advanced on-site laboratories.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Hydrostatic Pressure Testing to ISO 9080 and ASTM D2837

Element's hydrostatic pressure testing measures long-term strength of plastic pipes per ISO 9080 and ASTM D2837 standards. This service assists resin manufacturers, pipe extruders, and certification bodies with product classification.