Compression Testing

Verify your materials' strength and durability with Element’s comprehensive compression testing, to reveal weaknesses before they become costly problems. From aerospace components to building materials, get precise, reliable data that meets regulatory requirements and prevents product failures - giving you confidence in product performance and accelerating your path to market.

What is Compression Testing at Element?

Compression testing evaluates a material's ability to withstand forces that squeeze or compress, causing it to become shorter or compacted. At Element, we provide comprehensive compression testing services for diverse materials and components, from metals and polymers to rubber and timber. Our testing identifies potential weaknesses, validates structural designs, and confirms your products meet required specifications under real-world compression conditions - critical for ensuring structural integrity and performance.

We also offer specialized open hole compression testing, which simulates flaws in composite components or areas requiring fastener holes, using a side support fixture to prevent Euler buckling and ensure the only acceptable failure occurs at the hole.

What Can Element Offer You For Compression Testing?

Key tests offered

Key tests offered

Get precise data on your materials' compression behavior with our comprehensive test portfolio. From basic compression strength measurements to specialized tests like compression after impact (CAI) and open hole compression, we deliver the exact insights you need to validate product performance and meet industry requirements across aerospace, automotive, defense, and medical sectors.

- Compression strength and set testing

- Compression after impact (CAI) for composite evaluation

- Open hole and filled hole compression testing

- Compressive force and stress-strain characteristics

- Combined loading compression and stress relaxation

- Edgewise and flatwise compression for sandwich structures

- Core and sandwich compression testing

Components and materials we test

Components and materials we test

Access specialized testing for a wide range of materials and components, including shipping containers, structures, foams, metals, coatings, polymers, rubber, and timber. Our laboratories handle everything from simple compression tests to complex evaluations like compression after impact, stress relaxation and open hole compression, giving you complete confidence in your material's performance under pressure.

- Shipping containers and packaging systems

- Metal components and nuts

- Polymer matrix composites (PMCs)

- Rubber and elastomers

- Timber materials (parallel and perpendicular to grain)

- Structural adhesives and glare materials

- Composite sandwiches and laminates

Methods and solutions offered

Methods and solutions offered

Address your unique testing challenges with our adaptable testing programs. Whether you need standard compression testing or custom setups for specialized materials, our experts configure the right methodology to deliver actionable results. We accommodate temperature variants from -70°C to 320°C, ensuring your materials are tested under relevant environmental conditions for your specific application needs.

- Custom compression testing programs for unique requirements

- Temperature variance testing from -70°C to 320°C

- Specialized testing for composite materials with side support fixtures

- Standard and custom test methodologies for diverse applications

- Testing for bolted or riveted composite joints using notched compression

- Flattening, crushing, compressive strength, uniaxial, lateral testing methods

- Young's modulus, Hooke's law, and buckling evaluation techniques

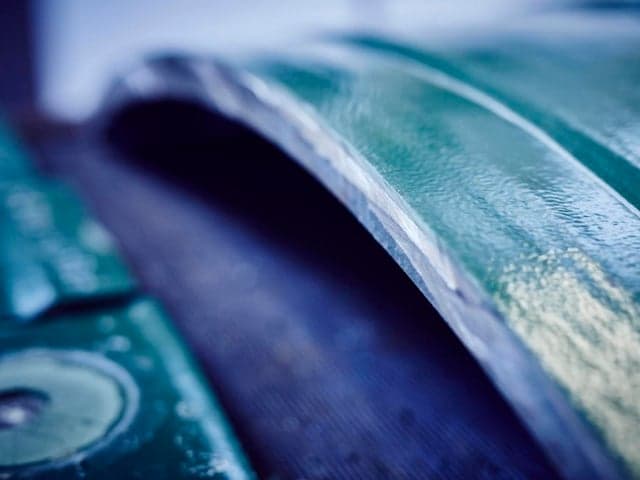

Advanced composite testing expertise

Solve complex material challenges with our specialized composite testing services, including open hole compression, filled hole compression, and compression after impact. These advanced tests simulate real-world conditions like fastener holes and potential damage, providing critical data for aerospace, automotive, and advanced manufacturing applications. Our expertise in analyzing how small inclusions or damages affect strength properties helps you design safer, more reliable composite structures for demanding applications.

Cutting-edge equipment we use

Cutting-edge equipment we use

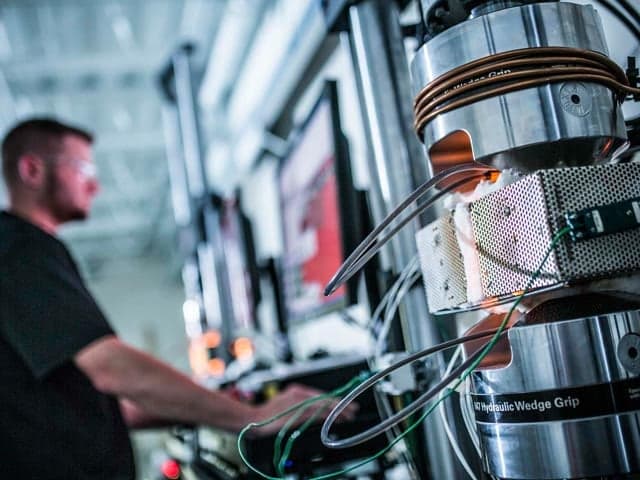

Gain reliable results from our state-of-the-art compression testing equipment across 27 global laboratories. Our adaptable labs accommodate both standard and custom test setups, with specialized fixtures like side support fixtures for open hole compression testing to prevent Euler buckling. Our advanced equipment allows for precise measurement of compression properties across a wide range of materials, providing you with only the most accurate data points for your critical applications.

Which labs offer this service

Which labs offer this service

Our 8,500-strong team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we meet and components we test

- ASTM D6484 (Open hole compression test)

- ASTM D6742 (Filled hole compression testing)

- Multiple aerospace, automotive, military, and general industry standards

Accreditations:

Aerospace and Aviation:

- Aerojet

- Airbus

- Boeing

- Bombardier

- Cessna

- Embraer

- GE

- Gulfstream

- Robinson

- ULA (United Launch Alliance)

Automotive and Transportation:

- Premium Aerotec

Healthcare and Pharmaceuticals:

- FDA (Food and Drug Administration)

- Health Canada

- GMP (Good Manufacturing Practice)

Military and Defense:

- Lockheed

- Northrop

Quality Management Systems:

Components/Equipment

- Shipping containers and systems - compression

- Compressive resistance (packaging/containers)

- Compression testing of structures (tests possible down to -180°C)

Foams

- Compression Set - strength, durability, and performance testing

Metals

- Compression testing - Including compressive, flattening, crushing, compressive strength, uniaxial, lateral, Youngs modulus, Hooke's law, buckling

- Compression testing of metallic metals

- Compressive properties testing

- Compression testing of nuts

Paint/Coatings

- Compression testing

Polymers

- Compression after impact testing (CAI)

- Compression testing - covering flattening, crushing, compressive strength, stress-strain, uniaxial, lateral, youngs modulus, Hooke's law, and buckling methods

- Compression after impact properties of oriented fibre resin composites

- Compression set

- Compression set (at low and ambient temperatures)

- Compression Set Testing (method B)

- Compression strength testing

- Core/sandwich compression

- Stress-strain characteristics in compression

- Compression testing of adhesives

- Compression testing of composites

- Compressive force testing

- Compression stress relaxation (CSR)

- Compression after impact (CAI)

- Compressive properties (PMCs)

- Edgewise compression testing

- Flatwise compression testing

- Compression of glare materials

- Combined loading compression

- Compression strength

- Sandwich beam compression

- Open hole compression + compression fatigue

- Filled hole compression

Rubber

- Compression Set

- Compression set (at low and ambient temperatures)

- Compression Set Testing (method B)

- Compression strength testing

- Compressive force testing

Timber

- Compression test parallel to the grain

- Compression test perpendicular to the grain

Your Challenges, Our Solutions

Ensuring performance of critical applications

Meeting global standards compliance

Catching defects and issues quickly

Unique testing needs

Element Experts at your service

Why Choose Element

Customized Compression Testing Programs

Globally Certified, Locally Accessible

Performance That Sets You Apart

Experts, Equipment, and Innovation

Frequently asked questions

What is the difference between Compression Testing and Tensile Testing?

Compressive forces push inward on an object, aiming to reduce its size or volume. Whereas tensile forces are the opposite – they pull or stretch an object. These two tests therefore reveal different aspects of material properties, and are often used in conjunction for a comprehensive assessment of performance.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.