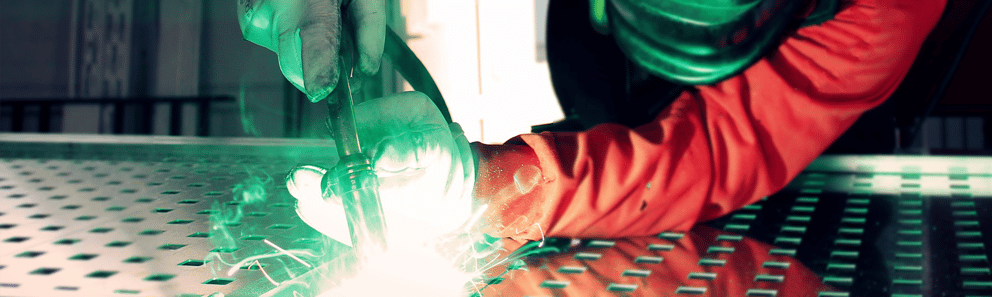

Welding Fume Exposure Monitoring Services

Protect your workforce and ensure full HSE compliance with Element's comprehensive welding fume exposure monitoring services. Our expert team delivers precise measurements, practical solutions, and actionable recommendations to safeguard your workers from hazardous welding fumes, comply with COSHH regulations, and maintain operational efficiency. We combine state-of-the-art monitoring equipment with one of the UK’s largest occupational hygiene teams to deliver results you can trust.

What is Welding Fume Exposure Monitoring Services at Element?

Our welding fume exposure monitoring service measures and assesses your workers' exposure to hazardous airborne substances produced during welding processes. Using specialized equipment and expert analysis, we collect air samples, analyze fume composition and concentration, and provide detailed recommendations for control measures that protect your workforce while ensuring regulatory compliance.

What can Element offer you for Welding Fume Exposure Monitoring Services?

Key services offered

Key services offered

Element's comprehensive approach includes personal welding fume monitoring, workplace air monitoring, and detailed assessment of control measures. We provide LEV system testing according to HSG258 guidelines, face fit testing for respiratory protective equipment, and complete COSHH risk assessments. Our practical solutions are tailored to your specific welding operations and workplace environment.

Components and materials we test

Components and materials we test

We comprehensively test all welding fume components against Workplace Exposure Limits (WELs) as outlined in the HSE's EH40 document. Our advanced monitoring equipment precisely measures metal fume concentrations including aluminum, chromium, iron, manganese, and nickel. We analyze both indoor and outdoor welding environments to ensure complete coverage of your operations.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art welding fume monitoring equipment delivers precise measurements and reliable data. All analytical work is conducted in UKAS-accredited laboratories participating in the AIR PT scheme, ensuring the highest accuracy and reliability in results. Our advanced monitoring technology enables us to detect and measure even trace amounts of hazardous fumes.

Which labs offer this service

Which labs offer this service

Our team operates from environmental testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest environmental testing hub is on our Locations Page.

Health and safety compliance

Health and safety compliance

We ensure your welding operations meet all current HSE requirements, including the latest guidance stating that no welding can be undertaken without suitable monitoring and control measures. Our comprehensive service helps you implement and maintain effective engineering controls and RPE programs, keeping you compliant with evolving regulations.

Standards we test to and materials we test

- HSG173 Monitoring strategies for toxic substances

- BS EN ISO 10882 ‘Health & Safety in Welding and Allied Processes - Sampling of Airborne Particles and Gases in the Operator’s Breathing Zone’

- Aluminum welding fumes

- Chromium welding fumes

- Iron welding fumes

- Manganese welding fumes

- Nickel welding fumes

- General welding gases

- Airborne particles

- Residual fumes

- Indoor and outdoor welding emissions

Your Challenges, Our Solutions

HSE Compliance Concerns

Carcinogenic Health Risks

Uncertain Control Measures

Training and Implementation

Why Choose Element

Global Leadership

Technical Excellence

Practical Solutions

Complete Service Integration

190+years

8,500+experts

100%fully UKAS-accredited

#1first largest occupational hygiene team

Frequently asked questions

Is exposure to welding fumes harmful?

Yes. The International Agency for Research on Cancer (IARC) has classified all welding fumes as Group 1 carcinogenic to humans. All types of welding fumes, including fume from mild steel welding can cause several health conditions including lung cancer, kidney cancer, COPD, asthma, metal fume fever, siderosis, stomach ulcers, renal damage, and neurological effects similar to Parkinson’s disease (Manganism).

What are welding fumes exposure limits?

The Health & Safety Executive document EH40 contains a list of Workplace Exposure Limits (WELs) for use with COSHH.

|

Substance |

WEL |

|

Aluminum |

10 mg/m3 |

|

Chromium |

0.5 mg/m3 |

|

Iron |

5 mg/m3 |

|

Manganese |

0.2 mg/m3 |

|

Titanium |

10 mg/m3 |

|

Nitrogen Oxide |

2.5 mg/m3 |

|

Nitrogen Dioxide |

1.91 mg/m3STEL |

|

Copper |

0.2 mg/m3 |

|

Nickel |

0.1 mg/m3 |

|

Ozone |

0.4 mg/m3STEL |

|

Chromium VI (process generated) |

0.025 mg/m3 |

Note: TWA = Time Weighted Average

STEL = Short Term Exposure Limit

The WELs above are based on an average 8-Hour Time Weighted Average (TWA) of exposure. Some substances have Short Term Exposure Limits (STEL) where concentrations must not exceed the limit over 15 minutes.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Environmental Compliance Services

Need reliable hydrocarbon testing? Element delivers precise analysis of water and soil samples to ensure regulatory compliance and prevent environmental issues. Our advanced labs provide fast, accurate results for all your testing needs.

Breathing Air Quality Testing

Element's Breathing Air Quality Testing ensures safe, contamination-free air for workplace safety. Accredited under ISO 17025, we test all key contaminants while minimizing disruption through efficient, multi-service visits. Stay compliant with BS EN 12021 and safeguard employee health with Element's expert support.

Face Fit Testing & Certificate for RPE Services

Element's face fit testing services ensure proper mask fitting for respiratory protection, delivering certified COSHH compliance. Our expert occupational hygienists provide quantitative testing and clear documentation to meet safety and legal requirements, with flexible scheduling and local support across the UK and Europe.

Local Exhaust Ventilation (LEV) Testing Services

Element's Local Exhaust Ventilation (LEV) testing services ensure full COSHH compliance with comprehensive system evaluations aligned to HSG258 guidelines. Our BOHS-qualified experts conduct thorough inspections to protect employee health, verify system performance, and provide actionable insights for optimization. With over 20 years of experience, we deliver trusted support for workplace safety and compliance.