Composite Damage Tolerance Testing

Mitigate risk and safeguard your composites with our end-to-end damage tolerance testing. Our drop weight impact and fracture toughness methods uncover hidden vulnerabilities early, offering hands-on guidance and fast turnaround for aerospace, automotive, and beyond. Rely on us to reduce in-service failures, optimize design, and meet stringent industry or custom standards efficiently.

What is Composite Damage Tolerance Testing at Element?

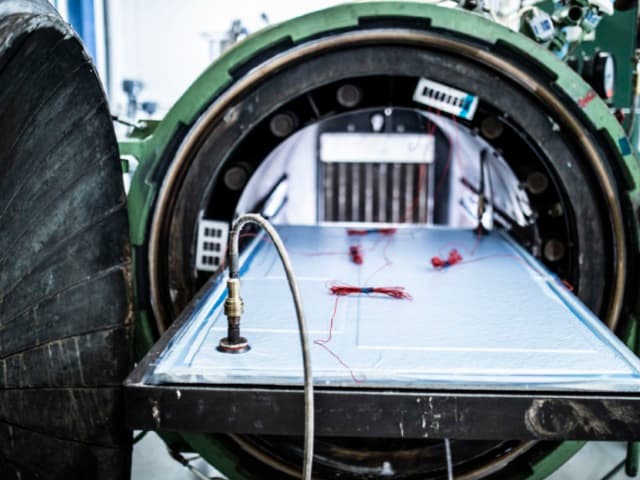

Composite damage tolerance is the capability of a damaged structure or laminate to maintain its original stiffness and strength—even when production or in-service damage occurs that is not always visible during inspections. At Element, we offer specialized testing methods including drop weight impact testing and fracture toughness testing to provide insights into your composite materials’ resistance, how damage may grow over time, and the critical data you need for risk mitigation.

What Can Element Offer You For Composite Damage Tolerance Testing?

Materials and components we test

Materials and components we test

We test a comprehensive range of composite structures, from flat and curved panels to multi-directional laminates used in high-performance industries such as aerospace, automotive, and defense. Our evaluations confirm whether these materials remain fit for purpose, mitigating the chance of unexpected failures in service. This proactive approach addresses both early-phase research and full-scale production needs.

- Fiber-reinforced composites

- Polymer matrix composites

- Laminate structures

- Complex curved components

- Aerospace-grade materials

Key tests offered

Key tests offered

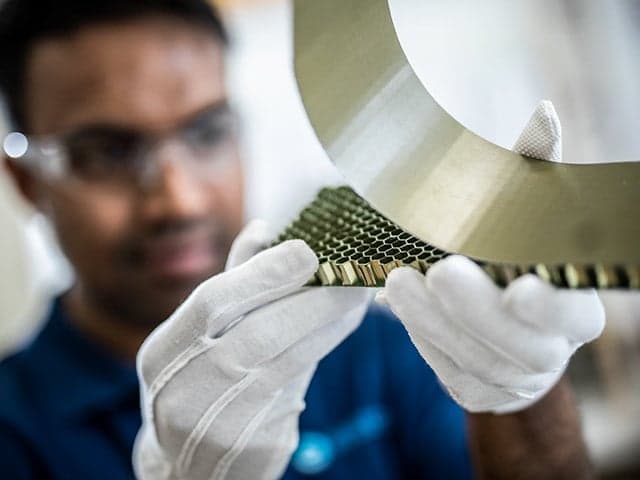

Our damage tolerance assessment includes drop weight impact testing to evaluate your composite’s resistance under various energies. We also perform Compression After Impact (CAI) testing to quantify how impact affects subsequent compression strength. In addition, fracture toughness testing (covering Modes I, II, III, and mixed modes) verifies delamination and crack propagation tendencies.

- Drop weight impact testing

- Compression After Impact (CAI) testing

- Fracture toughness testing

- Non-destructive inspection

- Barely Visible Impact Damage (BVID) assessment

Methods and solutions offered

Methods and solutions offered

We employ non-destructive inspection techniques to determine the extent and depth of hidden damage, capturing Barely Visible Impact Damage (BVID). For fracture toughness, we use specimens with pre-cracks to replicate in-service flaws. By combining these approaches, we provide comprehensive insights into a composite’s damage resistance. Our streamlined procedures deliver actionable data quickly—supporting your need for speed and convenience in design and production.

- Pre-crack simulation

- Multiple fracture modes (I, II, III)

- Mixed-mode testing

- Non-destructive inspection techniques

- Advanced damage measurement methods

Expert analysis and interpretation

Expert analysis and interpretation

Our material testing experts have broad experience evaluating both industry-standard and custom test standards, ensuring your unique requirements are met. We work closely with you to design programs that align with your specific performance goals. Detailed reports highlight potential vulnerabilities, guiding design modifications, manufacturing processes, or maintenance schedules to maximize service life and reliability.

- Customized testing programs

- Comprehensive performance analysis

- Regulatory compliance & custom standard support

- Design optimization recommendations

- Maintenance planning guidance

Which labs offer this service

Which labs offer this service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

Drop weight impact test standards

- AITM 1.0010

- ASTM D7136, ASTM D7766

- EN 6038

Fracture toughness test standards

- AITM 1.0005, AITM 1.0006, AITM 1.0053

- ASTM D5528, ASTM D6115, ASTM D6671, ASTM D7905

- EN 6033, EN 6034

- ISO 25217

(We can also accommodate client-specific or custom protocols to address specialized requirements.)

- Composite materials

- Fiber-reinforced composites

- Polymer matrix composites

- Carbon fiber composites

- Glass fiber composites

- Advanced composite laminates

- Pre-impregnated (prepreg) materials

- Composite structures

- Flat composite panels

- Curved composite sections

- Multi-directional laminates

- Unidirectional laminates

- Sandwich structures

Your Challenges, Our Solutions

Hidden damage causing costly failures

Making informed design decisions

Thoroughly assessing delamination risks

Standards compliance navigation

Why Choose Element

Comprehensive testing solutions

Material performance insights

Customized testing approaches

International standards expertise

Frequently asked questions

What is Barely Visible Impact Damage (BVID)?

BVID represents the threshold at which impact damage becomes visible upon inspection. Our testing helps determine this threshold by subjecting your materials to progressively higher impact energies and measuring resulting damage.

How does Compression After Impact testing work?

After controlled impact, we perform compression testing to measure strength loss caused by the damage. This shows how well your material maintains integrity after in-service impacts.

What's the difference between damage resistance and damage tolerance?

Damage resistance is a material’s ability to resist impact damage, while damage tolerance is its capacity to remain fit for purpose despite existing damage. Our tests evaluate both.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.