Examining Fiber-Reinforced Composite Materials

Detect and prevent costly defects early in manufacturing. Our hands-on examination of fiber-reinforced composite materials uses both microscopic and macroscopic methods, delivering fast, non-destructive insights that protect product integrity. Partner with Element to reduce risk, save time, and maintain quality, from initial production stages through final application – all with comprehensive, end-to-end convenience.

What is Examining Fiber Reinforced Composite Materials at Element?

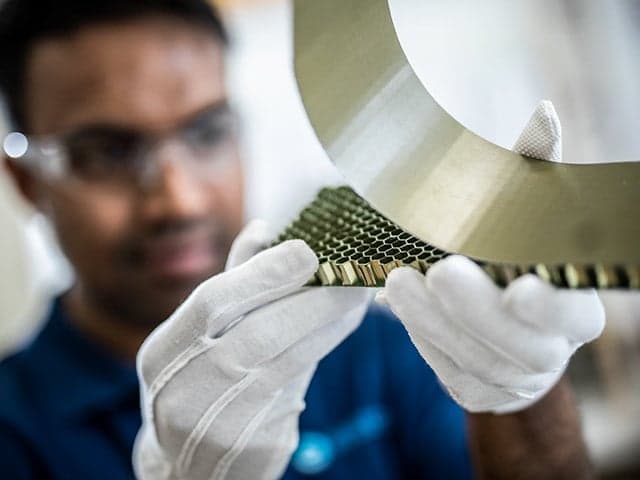

Fiber-reinforced composite materials combine two or more materials with different physical or chemical properties, often to reduce weight while maintaining or increasing strength. During manufacturing, it’s possible to introduce unwanted specimen defects—from micro/macrocracks and resin-rich areas to fiber undulations—that can undermine performance. At Element, we conduct early-stage examinations using both microscopic and macroscopic methods to provide robust insights without compromising material integrity.

What Can Element Offer You For Examining Fiber Reinforced Composite Materials?

Key Tests Offered

Key Tests Offered

Our examination services blend microscopic and macroscopic evaluations to capture both qualitative and quantitative data. With computer image analysis, we identify defects—from small cracks to fiber undulations—while preserving structural integrity. Our approach pinpoints potential manufacturing issues that can lead to expensive rework or in-service failures.

- Microscopic examinations for detailed defect analysis

- Macroscopic evaluations for overall part assessment

- Computer image analysis for non-destructive, quantitative data

- Sequential examination from part-level to sample-level analysis

- Defect characterization based on material tolerances

Materials we test

Materials we test

We evaluate a broad range of fiber-reinforced composites suited for weight reduction and structural applications. Our expertise spans:

- Polymer matrix composites (PMCs) with fiber reinforcements

- Metal matrix composites (MMCs) with metallic or non-metallic reinforcements

- Ceramic matrix composites (CMCs) with ceramic fibers in a ceramic matrix

- Fiber-reinforced materials for aerospace, automotive, and industrial applications

By examining these materials early in the production cycle, we help you mitigate manufacturing issues before substantial resources are invested in large-scale production.

Methods And Solutions Offered

Methods And Solutions Offered

Our systematic evaluation process typically starts with a macroscopic overview of each part, followed by a targeted microscopic inspection of suspect areas or representative samples. We identify various disadvantages of fiber-reinforced materials, including micro/macrocracks, resin-rich zones, porosity, delamination, and telegraphing, ensuring you have the data needed to reduce risk and save time and money long-term.

- Initial macroscopic exam for overall quality

- In-depth microscopic analysis for suspect areas

- Computer image analysis for robust defect quantification

- Material evaluation against your tolerances and pass/fail criteria

- Full-spectrum defect identification to address manufacturing challenges

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

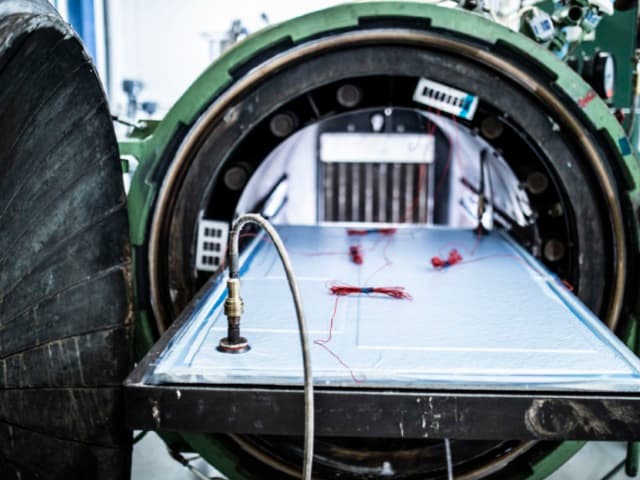

Our labs leverage advanced microscopy systems and imaging technology for precise identification of internal anomalies. Through non-destructive methodologies coupled with computer-assisted analysis, we provide detailed performance insights while preserving material integrity. This allows you to confidently adjust manufacturing processes and maintain the weight-saving advantages of composites without incurring late-stage failures.

- High-resolution microscopy for structural detail

- Advanced imaging for clear defect visualization

- Computer-assisted analysis for quantitative data

- Non-destructive examination tools that preserve material integrity

- Specialized instruments for fiber-reinforced composite defect identification

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Early defect detection

Early defect detection

Identifying potential manufacturing flaws in fiber-reinforced composite materials at the onset helps you mitigate risk and avoid costly rework or component failures down the line. By focusing on both microscopic and macroscopic examinations early, you can correct production processes before scaling up, enhancing reliability and reducing overall expenses.

Materials we test

The three main groups of fiber-reinforced composite materials include:

- Polymer Matrix Composite (PMC): Polymer base with fiber reinforcement

- Metal Matrix Composite (MMC): Metal base with metallic or non-metallic reinforcement

- Ceramic Matrix Composite (CMC): Ceramic fiber reinforcements within a ceramic matrix

Your Challenges, Our Solutions

Identifying manufacturing defects early

Quality verification with material integrity

Complex defect analysis results

Material-specific testing requirements

Why Choose Element

Fiber composite examination specialists

Computer-enhanced defect analysis

Systematic defect identification process

Material-specific evaluation criteria

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.