Concrete Testing Services

Ensure the reliability and performance of your concrete products – including anchors and masonry – with Element's comprehensive concrete testing services. From mix design to durability testing, our accredited laboratories provide precise, trusted results to help you meet industry standards, reduce risks, and avoid costly failures.

What are Concrete Testing Services at Element?

Concrete testing services ensure that your concrete and all concrete and masonry anchors consistently meet high-quality standards, adhering to strict industry specifications and intended design life. Element provides a wide range of laboratory and on-site testing and inspection services for concrete and aggregates. These services evaluate new materials, assess the condition of in-situ concrete, and demonstrate compliance with regulations and quality standards. Our fully equipped, accredited materials testing laboratories are specifically dedicated to testing and analyzing both fresh and hardened concrete, along with its anchors.

What can Element offer you for Concrete Testing Services?

Components and Products We Test

Components and Products We Test

Element specializes in testing fresh and hardened concrete, including standard grades, high-performance concrete, shotcrete, self-compacting, and modified mixes.

We test all types of concrete and masonry anchors, including chemical, mechanical, screw, channel, cast-in specialty, and power-driven anchors. Our expertise extends to various cement types, including Ordinary Portland Cement (OPC), sulfate-resisting cement, Ground Granulated Blast Furnace Slag (GGBS), fly ash, and silica fume mixes.

Detailed Testing Coverage:

- Fresh concrete mixes

- Hardened concrete specimens

- Modified and specialty concrete formulations

- All anchor types for concrete/masonry

- Various cement and admixture combinations

Key Tests Offered

Key Tests Offered

We provide end-to-end concrete testing—from fresh workability assessments to hardened durability analysis. Our core testing services include:

Concrete Testing:

- Chloride penetration resistance and chloride permeability

- Compressive and flexural strength testing

- Initial Surface Absorption Test (ISAT)

- Chloride and sulfate testing

- Water permeability testing

- SCRF flexural tensile strength testing

- Limit of Proportionality (LOP)

- Static creep testing

- Core drilling and testing

- Pull-off and pull-out testing

- Concrete bond strength tests

- Drop test (BRE screed tester)

- Rebound hammer / Schmidt hammer test

- Ultrasonic Pulse Velocity (UPV)

- Concrete cover measurement

- Carbonation depth analysis

- Half-cell potential testing

- Alkali-silica reaction assessments

- Petrographic examination

- Alkali reactivity of aggregates

- Drying shrinkage analysis

- Static Modulus of Elasticity and Poisson’s Ratio

- Sulfate resistance

- Portland Cement Concrete (PCC) testing

- Flash ash content analysis in PCC

- Concrete curing compound assessments

- Bleeding test of concrete

- Blaine air permeability cement fineness

- Cement consistency and setting time

- Heat of hydration testing

- Cylinder compressive strength testing

- Chloride diffusion coefficient testing

- Durability and crack width/movement evaluations

- Testing High-Strength Concrete (HSC) for compressive strength

Anchor Bolt Testing:

- Static Tension

- Static Shear

- Static Oblique

- Seismic Shear

- Seismic Tension

- Cracked Concrete Testing (static, cyclic)

- Environmental Condition Testing (freeze-thaw, elevated/decreased temperatures, alkaline exposure, sulphur exposure, etc.)

- Chemical and Metallurgical Analysis

- Failure Analysis

- Creep Testing

- Wet/Submerged Installation Testing

- Hydrogen Embrittlement Testing (Method A)

Methods and Solutions Offered

Methods and Solutions Offered

Our services cover everything from pre-construction reviews to existing structure assessments, with both laboratory and on-site testing capabilities. We use destructive and non-destructive testing solutions to evaluate structural performance and compliance with industry standards.

How our team supports your testing:

- Pre-construction consultation

- On-site testing and monitoring

- Laboratory analysis

- Quality control programs and Compliance documentation

- Digital reporting systems

- Full trial mix facilities

- Non-destructive evaluation techniques

Cutting-edge Equipment We Use

Cutting-edge Equipment We Use

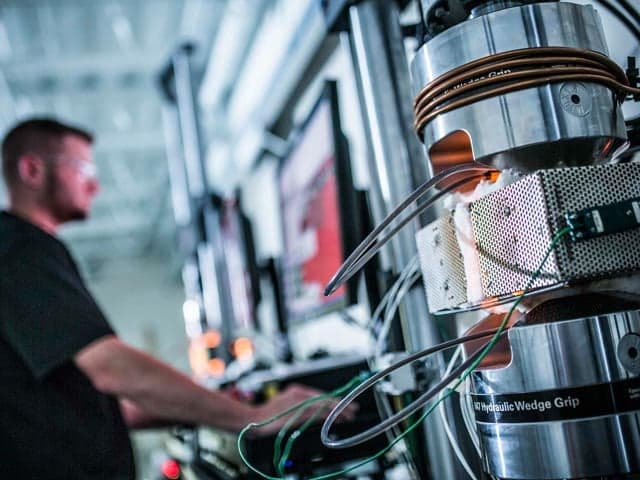

Our laboratories are equipped with industry-leading testing technology, including specialized adiabatic calorimeters for temperature control testing and custom equipment for cracked concrete anchor testing and durability assessments.

Labs Offering This Service

Labs Offering This Service

Element operates accredited materials testing laboratories worldwide, including key hubs in Singapore (Tuas Loop) and Malaysia (Johor)—formerly known as Admaterials. Our anchor bolt testing expertise is led by Element St. Paul. With over 20 years of experience our ICC-certified scientists and engineers actively contribute to the development of industry testing procedures and standardization efforts.

Standards we meet and products we test

British Standards

- BS EN 196, NTB 492, C1202, BS 1881, BS EN 12390, DIN 1048, BS EN 14651, BS EN 12350, BS EN 1744, BS EN 932, BS EN 933, BS EN 1367, BS EN 12504, BS EN 1097, BS ISO 1920-9, BS EN 12390-17, C512 / C512M, C876, BS EN 206, BS EN 197, BS EN 450, BS EN 480, BS 812, BS EN 1008, BS 3148, BS EN 12620.

ASTM

- A 615, A 820, C 29 / C29M, C 39 / C39M, C 40 / C40M, C 42 / C42M, C 78 / C78M, C 88, C 109 / C109M, C 117, C 127, C 128, C 131, C 136, C 138 / C138M, C 142 / C142M, C 143 / C143M , C 157 / C157M, C 173 / C173M, C 190, C 192 / C192M, C 215, C 215, C 231 / C231M, C 260, C 330 / C330M, C 348, C 482, C 494 / C494M, C 511, C 535, C 566, C 567, C 617 / C617M, C 618, C 880 / C880M, C1018, C1064, C1116 / C1116M, C1231 / C1231M, C1399 / C1399M, C1579, C1609 / C1609M, E 488, E1512, C1240, C1602/ C1602M, C1157 / C1157M, C1152 / C1152M, C1084, C1074, C1038 / C1038M, C1017 / C1017M, C1012 / C1012M, ASTM C989 / C989M, C900, C856 / C856M, C805 / C805M, C496 / C496M, C494 / C494M, C469 / C469M, C452, C403 / C403M, C311 / C311M, C309, C295 / C295M, C289, C266, C232 / C232M, C227, C204, C192 / C192M, C191, C186, C150 / C150M, C31 / C31M, C1556.

Anchor bolt testing

- ACI 355.2-04/355.2R-04

- ASTM C1354 / C1354M

- ASTM E 488

- ASTM E1512

- ICC-ES AC 01

- ICC-ES AC 58

- ICC-ES AC 70

- ICC-ES AC106

- ICC-ES AC193

- ICC-ES AC232

- ICC-ES AC308

- ICC-ES AC446

- City of Los Angeles, California

- Miami-Dade BCCO

Concrete Types:

- Fresh Concrete Mixes

- Hardened Concrete Specimens

- Modified Concrete Formulations

- Specialty Concrete Types (e.g., Shotcrete, Self-Compacting, High-Performance Modified Mixes)

Anchor Types for Concrete/Masonry:

- Chemical Anchors

- Mechanical Anchors

- Screw Anchors

- Channel Anchors

- Cast-in Specialty Anchors

- Power-Driven Anchors

Cement Types:

- Ordinary Portland Cement (OPC)

- Sulfate-Resisting Cement

- Ground Granulated Blast-Furnace Slag (GGBS)

- Fly Ash

- Silica Fume Mixes

Admixtures & Other Components:

- Various Cement and Admixture Combinations

Your Challenges, Our Solutions

Ensuring Compliance

Maintaining Long-Term Durability

Preventing Costly Concrete Failures

Assessing In-Situ Concrete Condition Accurately

Why Choose Element

Comprehensive End-to-End Services

Cutting-Edge Testing Technology

ICC-Certified Testing Experts

Industry-Leading Durability Testing

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

What types of building standards and regulations do your concrete testing services comply with?

Our testing services comply with internationally recognized BS, EN, and ASTM standards.

What specific types of testing do you offer for self-compacting concrete?

For self-compacting concrete, we provide specialized testing including: slump flow, V-funnel, L-box, and adiabatic tests.

When is adiabatic testing particularly important for concrete?

Adiabatic testing is crucial for mass concrete sections where heat dissipation is slower than heat generation, ensuring performance in thick concrete sections.

What comparative quality testing methods do you use for existing structures?

We use tests like the Rebound hammer (Schmidt Hammer test), BRE screed tester, and Pulse Velocity (PUNDIT) to assess structural integrity.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Geotechnical Engineering Services

Ensure a strong foundation with our Geotechnical Engineering Services. Including expert instrumentation and monitoring, soil investigation and soil & rock analysis for safe, durable, cost-effective builds. Learn More.

Aggregate Testing Services

Element provides comprehensive aggregate testing services, evaluating strength, durability, and composition to support construction projects with accurate, compliant, and high-quality material assessments.

Masonry Materials Testing Services

Element provides expert masonry testing, ensuring compliance with industry standards, reliable performance, and durability for your materials, helping you avoid delays and optimize project outcomes.

Ground Penetrating Radar Testing

Element's experts provide a full spectrum of non-destructive evaluation and non-destructive testing services for concrete structures and materials.