Air Tightness and Water Penetration Testing Services

Protect your building investment with precise air tightness and water penetration testing. Prevent energy loss and costly moisture damage and validate the airtight and watertight performance of your building enclosure materials before installation. Elements' combined testing approach delivers certainty for your entire building enclosure system, from design through construction.

What is Air Tightness and Water Penetration Testing at Element?

Air Tightness and Water Penetration Testing measures the ability of building materials and assemblies to resist air leakage and moisture infiltration. These tests help ensure optimal energy efficiency, prevent costly moisture damage, and improve occupant comfort. At Element, we provide comprehensive air tightness and water penetration testing services for a wide range of building materials and assemblies, from air barriers to fenestration systems. Our testing adheres to national and international standards, providing critical data to validate the performance of your building envelope before installation.

What can Element offer you for Air Tightness and Water Penetration Testing?

Components and materials we test

Components and materials we test

From air barriers to complete fenestration assemblies, Element can test your entire building enclosure system. Our expertise spans various air barrier systems and fenestration systems including:

- Peel-and-stick membranes

- Liquid spray or trowelled applications

- 1 and 2-component spray foams

- Woven and non-woven wraps

- EPS and XPS foam boards

- Residential and commercial windows and doors

- Curtain walls

- Pressurized and back-ventilated rain screens

- Various cladding types (sidings, claddings, etc.)

Our comprehensive testing ensures every component meets your performance requirements.

Key tests offered

Key tests offered

We test the air tightness and water penetration resistance properties of building materials and assemblies in accordance with the test methods prescribed by the major national and international standards. Our tests include:

- Air leakage rate measurements under various pressure conditions

- Water penetration resistance under uniform and cyclic pressure

- Combined air and water infiltration testing on complete assemblies

- Complete performance validation of building enclosure systems

Methods and solutions offered

Methods and solutions offered

Testing during the design and construction phases, as well as during building retrofits, prevents costly issues later in the project lifecycle. We evaluate both individual components and entire assemblies to provide detailed performance data that validates your materials meet air tightness and water resistance specifications. Early testing helps you avoid expensive corrections during construction or building operation.

We test the air and water tightness properties of building materials and assemblies in accordance with the test methods prescribed by the major national and international standards for determining their air leakage rate and the resistance to water penetration.

Cutting-edge equipment we use

Cutting-edge equipment we use

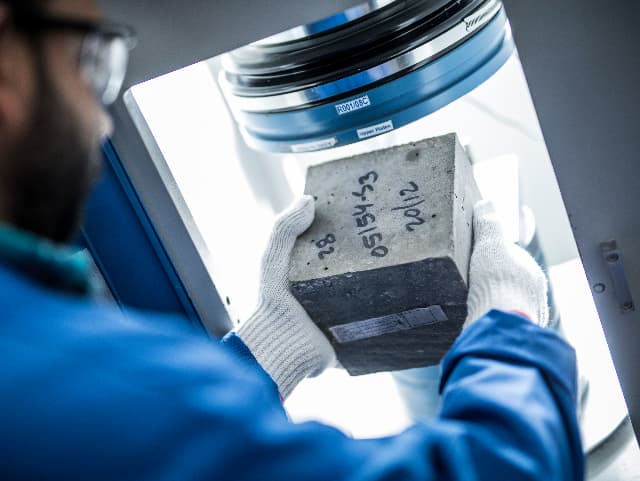

Our state-of-the-art laboratory equipment enables accurate and reliable measurement of air leakage rates and water penetration resistance under both static and cyclic pressure conditions. Our facilities support the testing of full-scale building enclosures and assemblies to ensure real-world performance validation.

Which labs offer this service

Which labs offer this service

Our team operates from hubs across the world, providing global access to our expert capabilities. Find your nearest hub on our Locations Page.

Standards we test to and products we test

Air Tightness Testing Standards:

- ASTM E283

- ASTM E2178

- ASTM E2357

- CAN/ULC S741

- CAN/ULC S742

- NAFS-11 and 17

Water Penetration Testing Standards:

- ASTM E331

- ASTM E1105

Element's experts have a thorough knowledge of air tightness testing, and our laboratory is outfitted with advanced equipment that allows us to test various types of air barrier assemblies and systems used in building enclosures. These include:

Wall assemblies:

- Peel and stick membranes

- Liquid spray or troweled applied

- Silicone spray or troweled applied

- Woven or non-woven wraps

- 1 and 2 component spray foams

- EPS or XPS foam boards

Fenestration assemblies:

- Residential and commercial windows and doors

- Window walls

- Curtain walls

Cladding assemblies:

- Pressurized rain screens

- Back-ventilated rain screens

- Sidings

- Claddings

Your Challenges, Our Solutions

Rising Energy Costs

Risk of Water Damage

Compromised Air Quality and Comfort

Meeting Compliance Requirements

Why Choose Element

Complete Testing Solution

Early Problem Prevention

Advanced Technical Capabilities

Global Expertise, Local Service

Frequently asked questions

When is the best time to conduct air tightness testing?

Testing is most valuable during the design phase and construction process of new buildings and retrofits. Early testing ensures that all air tightness targets are met, preventing costly issues during the building's service life.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Environmental Testing Services

Our experts and network of accredited laboratories offer environmental testing services for water, soil, sediments, waste, air quality, emissions and more. Learn More.

Infrastructure Testing Services

Element provides industry-leading infrastructure testing services, helping construction and civil engineering projects improve safety, meet regulations, and optimize performance with expert analysis and advanced on-site laboratories.

Architectural Acoustics Testing

Element provides advanced architectural acoustics testing to assess sound absorption and transmission, helping construction professionals enhance noise control and meet regulatory requirements.

Cladding and Facade Testing

Element provides expert cladding and facade testing to assess air leakage, water penetration, and structural integrity. Our advanced labs support compliance, energy efficiency, and long-term building performance.

Dynamic Wind Uplift Testing Services for Roof Membrane Systems

Element is at the forefront of dynamic wind uplift testing, providing tests of MARS, PARS, and AARS systems to CSA A123.21 and CAN/ULC-S742.

Fenestration Testing

Element is at the forefront of fenestration testing, providing a comprehensive suite of laboratory testing, field performance evaluation, and failure analysis services specifically tailored to the construction industry.

Accelerated Weathering Testing Services

Element's accelerated weathering testing services evaluate durability under harsh conditions, helping you mitigate premature product failures, maintain quality standards, and achieve confidence in real-world performance for consistent success.