Avionics Systems Testing

Accelerate your commercial, defense, and business/general avionics testing and certification with Element's end-to-end testing services. From complex system integration and battery technologies to EMC/EMI validation, our aerospace and defense experts provide hands-on guidance throughout your product journey, helping you navigate rigorous regulatory requirements while meeting critical timelines. With specialized laboratories in global aerospace hubs, we ensure your avionics systems achieve optimal performance, compliance, and reliability across both commercial and military applications.

What is Avionics Systems Testing at Element?

Avionics testing evaluates the performance, safety, and reliability of aircraft electronic systems under various operational conditions. At Element, we provide end-to-end testing services for flight management systems, navigation equipment, communication devices, displays, and flight control systems. With 80+ years of commercial, defense, and business/general aerospace experience and ISO/IEC 17025 accredited laboratories, we ensure your avionics components meet critical standards including RTCA DO-160, MIL-STD-461, and manufacturer-specific requirements like Airbus ABD0100 and Boeing standards.

What can Element offer you for Avionics Systems Testing?

Key tests offered

Key tests offered

Our avionics testing services cover the full spectrum of qualification requirements essential for airworthiness certification.

Our comprehensive testing capabilities include:

- Environmental simulation testing (temperature, altitude, humidity, vibration)

- EMI/EMC testing to RTCA DO-160, MIL-STD-461 and other standards

- Power quality testing at exceptional capacity levels:

- AC: up to 500 Volts per phase, 250 Amps 3-phase, 750 Amps single-phase

- DC: up to 700 Volts, 1200 Amps

- Radio frequency susceptibility testing

- HIRF (High Intensity Radiated Fields) testing

- Emissions testing per military and commercial standards

- Direct and Indirect Lightning effects testing

These capabilities ensure your avionics meet all regulatory requirements across both commercial and military applications.

Components and products we test

Components and products we test

We provide comprehensive testing solutions for the complete range of avionics systems and components, from individual circuit boards to fully integrated systems.

We also test the materials used in avionics components, including:

- Metals and alloys (aluminum, titanium)

- Printed circuit boards

- Connectors and wiring

- Adhesives and coatings

- Polymer components

- Composite materials

- Battery technologies

Whether you need environmental testing for small components or full system-level integration validation, our global facilities are equipped to handle your avionics testing needs across all phases of development.

Methods and solutions offered

Methods and solutions offered

We tailor our testing approaches to your specific avionics components, offering customized test programs that address your unique technical challenges while meeting all regulatory requirements. As a single-source partner for all your avionics testing needs, our experts guide you through the entire qualification process, from test plan development to final certification support.

Our comprehensive solutions approach includes:

- Combined test phases to streamline certification timelines

- Integration of defense and commercial standards into single test programs

- Early Stage Qualification (ESQ®) service to accelerate product development

- Complete documentation packages supporting regulatory submissions

- Digital engineering combined with physical testing for comprehensive validation

- Secure testing protocols for classified or sensitive military avionics

- ITAR/EAR compliant processes for handling controlled information

- Compliance assurance with FAR and DFARs regulations

These capabilities ensure your avionics systems achieve certification efficiently while maintaining the highest standards of safety and security.

Cutting-edge equipment we use

Cutting-edge equipment we use

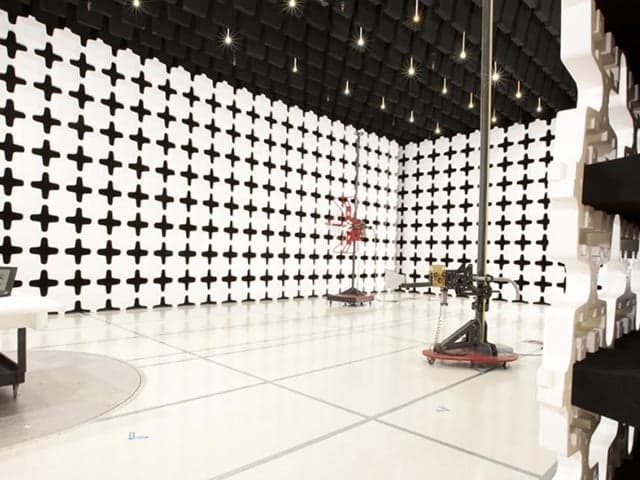

Our laboratories feature state-of-the-art equipment to provide the most accurate and comprehensive testing for your avionics systems.

Our specialized testing equipment includes:

- Fully anechoic RF chambers for precise EMC testing

- Advanced EMC test systems with exceptional capabilities

- Environmental simulation chambers replicating extreme aerospace conditions

- Power quality test systems with customizable parameters:

- AC power: up to 500 Volts per phase, 250 Amps 3-phase, 750 Amps single-phase

- DC systems: up to 700 Volts and 1200 Amps

- Customizable surge/interruption transient generators with extremely fast slew rates

- Hundreds of environmental chambers for comprehensive environmental testing

- More than a hundred dynamics systems for vibration, shock, and acceleration testing

This extensive equipment base allows us to simulate virtually any operational scenario your avionics may encounter, ensuring thorough qualification against all relevant standards.

Which labs offer this service

Which labs offer this service

Element's avionics testing services are available at our aerospace-focused laboratories strategically located in key global aerospace manufacturing hubs. Our facilities maintain ISO/IEC 17025 accreditation with specialized capabilities for RTCA DO-160, MIL-STD-461, and DEF STAN 59-411 testing.

With defense testing centers across the USA, UK and South Korea, including 15 dedicated DEF STAN 59-411 EMC chambers originally built for military vehicle testing, we offer unmatched capacity for both commercial and military avionics testing.

Standards we test to and the products we test

Commercial Standards

- RTCA/DO-160 (all sections)

- Eurocae ED13

- Eurocae ED14

Airbus Standards

- Airbus ABD0100.1.2 (including Issue G)

- Airbus ABD0100.1.8

- Airbus ABD0100.1.8.1

- Airbus AMD-24 A/B/C

Boeing Standards

- Boeing 787B3-0147

- Boeing D6-16050-4/-5/-6

Military Standards

- MIL-STD-461

- MIL-STD-462

- MIL-STD-704

- MIL-STD-1275

- MIL-STD-1399

- DEF STAN 59-411

- DEF-STAN 61-5

- EuroFighter SPE-J-000-E-1000

- MIL-PRF-28800

Power Quality Testing Standards

- RTCA/DO-160

- Airbus ABD0100.1.8

- Boeing 787B3-0147

- Flight management systems (FMS)

- Navigation equipment and systems (GPS, ADS-B, INS, VOR, ILS)

- Autopilot and flight control systems

- Communication systems (radios, SATCOM, datalinks)

- Power management units and distribution systems

- Display systems and controls (glass cockpits, HUDs, MFDs)

- Line replaceable units (LRUs)

- Circuit card assemblies (CCAs)

- Engine monitoring systems

- Aircraft health monitoring systems

- Flight data recorders

- Electronic flight bags

- Terrain awareness systems

- Radar altimeters and air data systems

- Wireless connectivity modules

- RF transmitters and receivers

- Electronic control units

We also test the materials used in avionics components, including:

- Metals and alloys (aluminum, titanium)

- Printed circuit boards

- Connectors and wiring

- Adhesives and coatings

- Polymer components

- Composite materials

- Battery technologies

Your Challenges, Our Solutions

Regulatory Complexity

Time-to-Market Pressure

System Integration Challenges

Security & Confidentiality Requirements

Why Choose Element

Dual-Sector Expertise

Security You Can Trust

Comprehensive Test Integration

Global Testing Leadership

80+Years Experience

35Nadcap-Accredited Labs

3,000+ Aerospace Experts

500+Defense Products Tested Annually

Frequently asked questions

What security measures do you provide for sensitive or classified avionics testing?

All testing is conducted in highly secure environments with strict confidentiality protocols. With over a decade of experience in ITAR/EAR jobs, Element North America and its subsidiaries are trusted suppliers to US government prime contractors. We maintain extensive experience handling CUI (Controlled Unclassified Information), ensuring complete compliance with FAR and DFARs regulations. Our secure testing facilities protect proprietary designs throughout the testing process, making us a trusted partner for sensitive military avionics.

What is the difference between RTCA DO-160 and MIL-STD-461 for avionics testing?

RTCA DO-160 is primarily focused on commercial aviation environmental requirements, covering factors like temperature, altitude, vibration, and EMI/EMC in a comprehensive standard. MIL-STD-461 specifically addresses electromagnetic interference for military applications with generally more stringent requirements. Many avionics systems, especially those used in both commercial and military aircraft, must comply with both standards. Our expertise in both allows us to create efficient test programs that address both simultaneously.

How does power quality testing affect avionics reliability?

Power quality testing is essential for avionics as it exposes susceptibilities to incoming power phenomena and characterizes what equipment passes back onto power lines. This testing ensures your systems can withstand power variations, surges, and transients that might occur during flight operations, preventing potential system failures or malfunctions that could compromise safety. Our power quality testing capabilities cover steady state/fault & emergency conditions, transients, surges and spikes at extremely high voltage and current levels with entirely tailorable parameters.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Aerospace EMI/EMC Testing

Element's aerospace EMI/EMC testing helps you meet commercial and military standards with tailored test plans, advanced facilities, and expert guidance to tackle compliance challenges and reduce delays.

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

MIL-STD-810 Testing Services

Element's MIL-STD-810 testing services validate military and defense products under extreme conditions, delivering reliable, accredited results for compliance and performance qualification.

RTCA DO-227 Non-Rechargeable Battery Testing

Element's aerospace battery test programs evaluate the fitness and durability of specialized batteries used in business and general aviation as well as EVTOL aircraft.

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.

Defense Electronic Component Testing

Element is a leading provider of defense electronic component testing to the world's most recognized OEMs and Tier suppliers. Using the latest test equipment, we carry out our electronic component testing in a secure environment, keeping the details of your product confidential at all times.

Lightning Strike Testing

Element's lightning strike testing helps your aircraft, infrastructure, and electronics withstand both direct and indirect lightning effects, reducing risk, supporting compliance, and protecting sensitive systems and materials. Learn More.

Aerospace

Element are the largest global independent provider of aerospace testing services with over 100 years of experience and world-class testing, qualification, calibration, and advisory services.

Defense Product and System Testing Services

Element has over 50 years of experience working with a wide range of Defense Product and System manufacturers from the initial concept of their products and on to the complex testing that is required of modern defense equipment.

- Aerospace Product Qualification Testing (PQT) Services

- Aerospace EMI/EMC Testing

- Aerospace RTCA DO-160 Testing

- MIL-STD-810 Testing Services

- RTCA DO-227 Non-Rechargeable Battery Testing

- Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

- Defense Electronic Component Testing

- Lightning Strike Testing

- Aerospace

- Defense Product and System Testing Services

RF and wireless testing capabilities

Our RF testing expertise ensures your avionics communication and navigation systems perform reliably while meeting strict regulatory requirements.

Our comprehensive RF testing services include:

- Signal strength and frequency accuracy measurement

- Modulation quality assessment

- Over-the-air testing in specialized anechoic chambers

- Antenna performance evaluation

- System-level integration testing

- Radio parametric testing for transmitters and receivers

- Interference analysis and mitigation

- Protocol conformance evaluation

- Real-life environment testing

- Certification support for regulatory compliance

Our facilities include the largest network of EMI chambers in North America, ensuring your wireless avionics components operate reliably without interference in complex electromagnetic environments.