Aerospace Composite Testing

Our aerospace composite testing services ensure your materials meet all the demands of modern aviation and space applications. From microscopic examination to comprehensive evaluation, we help you develop lighter, stronger components while catching potential issues early. With diverse technical expertise and active involvement in industry committees, we deliver accurate, reliable results that mitigate risk, save you time and money, and help you confidently push the limits of aerospace technology.

What Is Aerospace Composite Testing At Element?

Aerospace composite testing evaluates the performance, durability, and safety of advanced materials used in aircraft and spacecraft components. Through mechanical, chemical, thermal, and environmental testing, it ensures composites meet strict industry standards and performance requirements.

Here at Element, we provide comprehensive testing services for polymer matrix composites (PMCs) and fiber-reinforced materials used in aerospace applications. We evaluate material quality throughout the manufacturing process, to ensure compliance with ASTM standards and aerospace specifications.

What can Element offer you for Aerospace Composite Testing?

Key tests offered

Key tests offered

Element deliver a complete suite of testing services including mechanical, chemical, thermal, and environmental analysis. Our microscopic and macroscopic examinations identify potential defects early in the manufacturing process, from microcracks to delamination issues, helping you maintain quality while reducing costs.

- Mechanical testing (tensile, compression, shear)

- Compression after impact testing

- Fatigue testing (tension-tension, tension-compression, compression-compression)

- Fracture mechanics (interlaminar, translaminar, fatigue delamination growth)

- Chemical composition analysis

- Thermal performance evaluation (from -300°F to 3,000°F)

- Environmental conditioning tests

- Microscopic defect analysis

- Macroscopic structural examination

- Material property validation

- Damage tolerance assessment

- Durability testing

Components and materials we test

Components and materials we test

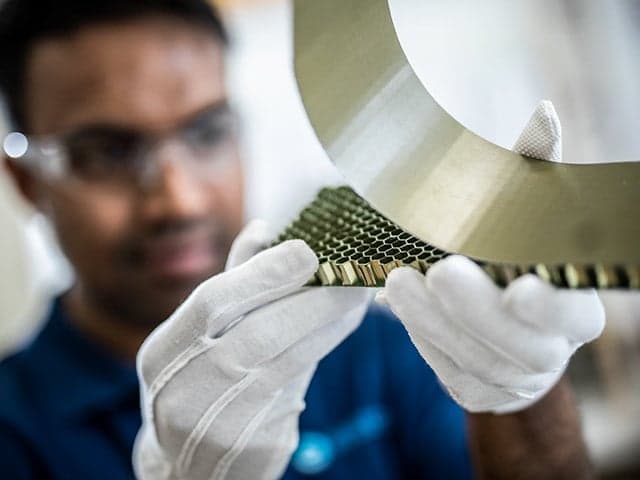

Our comprehensive testing capabilities cover the full range of aerospace composites, from structural components to interior materials. We specialize in evaluating Polymer Matrix Composites (PMCs), Fiber Reinforced Composites, and other advanced materials used throughout aircraft and spacecraft construction, helping you achieve significant weight reduction while maintaining strength requirements. Our evaluations ensure each component meets rigorous aerospace standards.

Methods and solutions offered

Methods and solutions offered

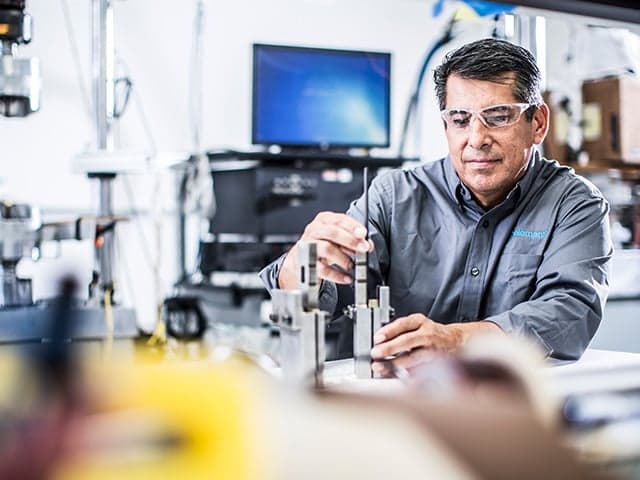

Our testing methodology follows strict ASTM standards. We work alongside your business to investigate materials according to specific tolerances and pass/fail criteria, ensuring comprehensive quality assurance throughout your development process.

We offer precision specimen preparation, including tight tolerance machining, radius creation and precision hole introduction to ensure the most accurate test results.

Industry expertise

Industry expertise

With active memberships in key industry committees including ASTM D30, CMH-17, ASTM C28, the Committee on Composite Materials and Nadcap, our experts bring diverse technical backgrounds to every project. Our breadth of experience examining microscopic and macroscopic samples allows us to help you get the most out of your materials throughout the development lifecycle. Our client approvals include GE S450, Airbus, Boeing, Bombardier, Embraer, Pratt & Whitney MCL, Sikorsky, and DLA, demonstrating our trusted status with leading aerospace manufacturers.

Which labs offer this service

Which labs offer this service

Our team operates from aerospace testing hubs across the world, providing global access to our expert capabilities. Among our many composites testing labs around the world, Element Los Angeles and Element Seville are Centers of Excellence in composite materials testing for the aerospace industry, with decades of specialized experience, and an international reputation for technical excellence.

Find your nearest aerospace testing hub on our Locations Page.

Standards we test to and materials we test

Polymer matrix composite testing

- ASTM C271

- ASTM C273

- ASTM C297

- ASTM C363

- ASTM C364

- ASTM C365

- ASTM C394

- ASTM C481

- ASTM D1002

- ASTM D2344

- ASTM D2583

- ASTM D2584

- ASTM D3039

- ASTM D3418

- ASTM D3479

- ASTM D3531

- ASTM D3532

- ASTM D5229

- ASTM D6272

- ASTM D6641

- ASTM D6742

- ASTM D6873

- ASTM D7137

- ASTM D7248

- ASTM D7249

- ASTM E1131

- ASTM D5528

- ASTM D5961

- ASTM D6484

- ASTM D5766

- ASTM D6671

- ASTM D7136

- ASTM D7291

- ASTM D6415

- ASTM D8387

Ceramic matrix composite testing

- ASTM C1161 - Flexural Strength

- ASTM C1275 - Tensile Strength

- ASTM C1292 - CFCC Shear Strength

- ASTM C1337 - Elevated Temperature Creep, Creep Rupture

- ASTM C1360 - Ambient Tension-Tension Cyclic Fatigue

- ASTM C1361 - Cyclic Fatigue

- ASTM C1425 - Elevated Temperature Shear Strength

Your Challenges, Our Solutions

Quality Control In Aerospace Manufacturing

Meeting Time-Critical Development Deadlines

Complex Regulatory Compliance

Performance Validation Challenges

Element Experts at your service

Why Choose Element

Aerospace Testing Leadership

Comprehensive Testing Expertise

Proven Industry Experience

Expert Technical Guidance

But don't just take our word for it

See what others say about partnering with Element...

Frequently asked questions

What types of defects can you identify in composite materials?

During testing, we can identify a range of manufacturing defects including micro and macrocracks, resin rich areas, porosity/voids, delamination, fiber undulations, poor edge consolidation, and telegraphing. Early detection of these issues helps prevent costly failures.

How do polymer matrix composites benefit aerospace applications?

Polymer matrix composites possess a high degree of stiffness and strength without the added weight of traditional materials. This makes them ideal for aerospace applications where reducing weight while maintaining structural integrity is critical. They've proven valuable across a wide range of aerospace components, from structural elements to interior materials.

At what stage of development should I engage Element for testing?

We can support your testing needs at any stage of material or product development. Early engagement helps identify potential issues before they become costly problems, but our experts are equipped to handle projects at any phase of your development cycle. We work alongside your business to achieve your desired results throughout the entire process.

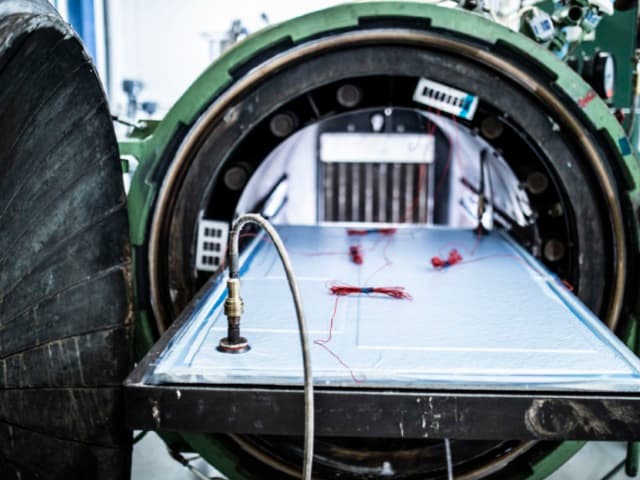

What temperature ranges can you test aerospace composites in?

Our testing capabilities cover extreme temperature ranges from -300°F to 3,000°F, allowing us to simulate the full spectrum of conditions your materials will encounter from cryogenic space environments to high-temperature engine components. This comprehensive temperature testing ensures your materials will perform reliably under all operational conditions.

Do you offer testing for space applications?

Yes, we provide specialized testing for space-bound composite materials including thermal vacuum testing, radiation exposure assessment, and evaluation of materials in simulated space environments. Our space simulation testing capabilities are backed by NASA recognition, making us an ideal partner for your most demanding space applications.

How is aerospace composite testing different from composites testing in other industries?

What makes aerospace testing unique is the extreme conditions these materials must withstand—from -300°F in space to 3,000°F in engine components—combined with the catastrophic consequences of failure. Every gram matters for fuel efficiency, yet materials must maintain performance for decades with minimal maintenance. Our evaluations ensure compliance with stringent FAA, EASA, and military standards throughout the manufacturing process.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Materials Testing

Our global network of 35 Nadcap accredited and aerospace supplier-approved aerospace materials testing laboratories provide a comprehensive range of materials testing services.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.