Lightning Strike Testing

Protect your critical systems from catastrophic lightning damage with comprehensive lightning strike testing - keeping aircraft, infrastructure and electronics operational even after direct strikes. Lightning vulnerabilities have increased with modern materials, but our customizable testing solutions help you overcome these challenges while meeting stringent industry standards and regulatory requirements.

What is Lightning Strike Testing at Element?

Lightning Strike Testing evaluates how well equipment and structures withstand the extreme electrical conditions caused by lightning strikes. Modern aircraft and ground facilities with sensitive electronics face increasing vulnerability to lightning damage. At Element, we provide comprehensive direct and indirect lightning protection testing for both aircraft and facilities, helping you meet stringent standards while safeguarding your most valuable assets from catastrophic electrical damage.

What Can Element Offer You For Lightning Strike Testing?

Components and materials we test

Components and materials we test

Element test a comprehensive range of aircraft and facility components that are vulnerable to lightning damage. We evaluate how your equipment responds to both direct and indirect lightning strikes, helping you identify potential vulnerabilities before they become costly failures. We evaluate:

Aircraft

From electronic avionics and fuel systems to composite structures and control equipment, our comprehensive testing covers all vital components. Our expertise extends to both traditional metallic and modern composite materials, ensuring your aircraft's safety regardless of construction:

- Aircraft electronics and control systems

- Composite airframe structures

- Fuel tanks and delivery systems

- Electrical wiring and connections

- Glass fiber components

Our specialized testing covers all protection levels required by RTCA DO-160 Section 22, offering military-grade protective assurance. Additionally, we test for all waveform methods and protection levels per RTCA DO-160 Section 22.

Facilities

We test lightning protection systems that protect buildings, including:

- Air Terminals (Lightning Rods)

- Grounding

- Bonding

- Shielding

- Surge Protection

- Circuit Design

Key tests offered

Key tests offered

Our lightning strike testing capabilities cover the full spectrum of lightning effects, from direct impacts to induced electrical transients. We provide testing that meets all major industry standards while accommodating unique project requirements with custom testing solutions tailored to your specific needs.

- Single stroke pin injection testing

- Single stroke cable bundle testing

- Multiple stroke testing

- Multiple burst testing

- Fuel systems ignition testing

- Electrostatic testing

- ESD testing

- High current testing

- High voltage testing

- Pin injection testing

- Cable bundling testing

Electronics testing:

In addition to lightning protection testing, we offer a range of mechanical, environmental and electrical tests for the integrity and performance of on-board or ground-based electronics, including:

- Operational reliability testing

Methods and solutions offered

Methods and solutions offered

We approach lightning protection holistically, going beyond simple compliance testing to ensure your systems are truly resilient. Our methods include specialized testing for both direct and indirect effects, with the flexibility to provide virtually any waveform transient required for your project's unique specifications.

- Comprehensive test programs for direct and indirect effects

- Customized waveform transients for unique requirements

- High-voltage generators for photographic testing

- Ignitable mixture testing for fuel systems

- Transient hot spot measurements

- Electrostatic charge accumulation testing

We offer a variety of lightning strike test methods, depending on the type of product being tested and the conditions being simulated.

Direct lightning testing methods:

- High current testing

- High voltage testing

Indirect lightning testing methods:

- Pin injection testing

- Cable bundle testing

Additional tests:

- Electrostatic testing

- ESD testing

Aircraft transient level testing:

We conduct aircraft transient level testing (whole aircraft testing) from test plan design through to data analysis. Critical avionic systems in aircraft need to be tested at an Equipment Transient Design Level (ETDL) which varies by aircraft/installation. Element can help you determine your ETDL via computational analysis.

Cutting-edge equipment we use

Cutting-edge equipment we use

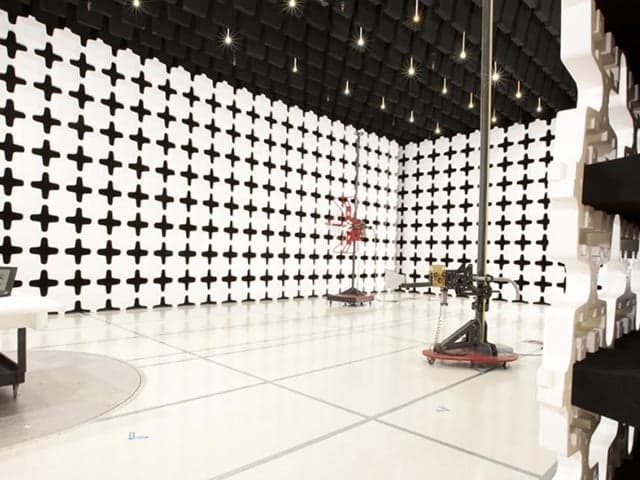

Our state-of-the-art testing facilities are equipped with specialized equipment that can simulate the full range of lightning effects. This advanced technology allows us to create precisely controlled test conditions that accurately replicate real-world lightning strikes while providing detailed data on how your components and systems respond to these extreme events.

- High-voltage generators

- Photographic testing equipment

- Waveform transient generators

- Electrostatic testing apparatus

- Environmental simulation chambers

Our capacity enables time-to-market advantages through shorter testing turnaround times. The test chamber at our Abingdon facility in the UK can accommodate sample sizes up to 3x3.5m, though larger samples can also be tested if required.

Which labs offer this service

Which labs offer this service

Our Element Pittsfield lab is world-renowned in the industry, offering decades of experience as Lightning Technologies. Other Element centers of excellence include Abingdon and Bloomington.

Standards we meet and the materials we test

- RTCA DO-160 Section 22

- MIL-STD-461

- DEF STAN 59-411

- Various commercial and defense specifications

Aircraft components

- Avionics and control systems

- Composite airframe structures

- Fuel systems and tanks

- Electrical wiring and connections

- Glass fiber components

Electronic equipment

- Aircraft electronics

- Onboard equipment

- Sensitive electronic systems

- Critical control equipment

- Communication systems

Your Challenges, Our Solutions

Advanced protection for modern materials

Regulatory compliance made simple

Critical systems continuously operational

Comprehensive protection strategies implemented

Why Choose Element

Lightning simulation expertise

Aircraft to facility protection

Comprehensive testing approach

Custom waveform capabilities

Frequently asked questions

How has lightning protection changed with modern materials?

The increased use of composite materials in aircraft and buildings has created new lightning protection challenges, as these materials don't naturally conduct electricity like metal. Our testing helps identify and address these vulnerabilities with specialized protection strategies designed for modern construction materials.

What are the major direct lightning test methods?

Lightning testing is carried out by the reproduction of lightning and its effects under laboratory conditions. There are a variety of lightning strike test methods available, depending on the type of product being tested and the conditions being simulated.

Direct lightning testing methods:

- High current testing where a lightning arc is created which can then replicate the effects of a lightning strike to an aircraft, both in terms of physical damage at the arc attachment location as well as looking at how the current distributes through the fuel system and critical structural elements.

- High voltage testing where the initial leader phase of a lightning strike, which can stress dielectric materials such as antennas, radomes and windscreens, is replicated.

What are the major indirect lightning test methods?

Indirect lightning testing methods include:

- Pin injection testing where lightning transients are applied directly into the pins of electrical products and systems to determine if they cause any damage. This is one of the most common test methods for assessing the effects of an indirect strike.

- Cable bundle testing which is designed to evaluate how the effects of current flowing on cable screens and overbraids affects equipment. There are several types of cable bundle testing: single stroke, multiple stroke, and multiple burst. The single stroke method replicates the effect of the initial return stroke current on equipment while the multiple stroke method replicates the effects of successive lightning attachments to an aircraft in a short duration. Multiple burst testing is designed to replicate the effects of leaders stepping away from the aircraft which can cause upset to equipment.

What other tests should typically accompany direct and indirect lightning strike testing?

Several other common tests in a complete lightning testing program include:

- Electrostatic testing, in which aircraft materials are tested to determine if accumulated charge poses a threat to fuel tanks, because the increased use of composites in fuels tanks can lead to the accumulation of static.

- ESD testing, which replicates the effects of charge accumulation on munitions due to handling (25kV), or from being carried by helicopter (300kV).

- Aircraft transient level testing (whole aircraft testing): Critical avionic systems in aircraft need to be tested at an Equipment Transient Design Level (ETDL) which is aircraft/installation dependent. Full vehicle testing, at low current, determines the Actual Transient Level (ATL) which must be greater than the ETDL.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

Aerospace EMI/EMC Testing

Element's aerospace EMI/EMC testing helps you meet commercial and military standards with tailored test plans, advanced facilities, and expert guidance to tackle compliance challenges and reduce delays.

DEF STAN 59 411 EMC Testing

Accelerate your defense qualification with Element's DEF STAN 59-411 environmental testing. Our accredited labs deliver complete military testing across all domains. Fast turnaround times for critical projects.

HALT & HASS Testing

Reduce product failures with our advanced HALT testing. Identify design weaknesses early using 6-DoF triaxial vibration and rapid thermal cycling. Expert engineers, faster time-to-market.

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.