Dielectric Strength Testing

Safeguard your products and users with fast, end-to-end dielectric strength and dielectric withstand testing. Our hands-on technical guidance and engaged experts ensure swift, accurate results that prevent electrical failures and protect against human injury. Trust Element’s global network to confirm compliance, optimize insulation materials, and deliver reliable performance under rigorous international standards.

What is Dielectric Strength Testing at Element?

Dielectric strength testing evaluates insulation materials’ resistance to harmful voltage in electronic devices. At Element, we conduct both dielectric strength and dielectric withstand tests to measure insulation barrier durability and determine maximum voltage tolerance before breakdown occurs. This fast, accurate testing helps protect humans from hazardous electrical currents and validates that your chosen materials can prevent serious injury or product damage.

What Can Element Offer You For Dielectric Strength Testing?

Key Tests Offered

Key Tests Offered

Element provide both dielectric strength testing to determine breakdown points, and dielectric withstand testing to measure performance over a set period under high voltage. Our AC and DC testing captures sudden changes in resistance, delivering precise data on both immediate and sustained insulation resilience. This quick turnaround lets you move from development to market with confidence.

- Dielectric strength breakdown testing

- Dielectric withstand duration testing

- AC voltage resistance testing

- DC voltage resistance testing

- Sudden resistance change analysis

Dielectric Withstand vs. Dielectric Strength

Dielectric tests apply high levels of alternating current (AC) or direct current (DC) to the insulation barrier:

- A dielectric strength test identifies the voltage at which material breakdown occurs, allowing current flow. This pinpointed voltage is the dielectric strength.

- A dielectric withstand test gauges how well insulation can tolerate high voltage for a specified time before failing.

Both tests are vital for product safety compliance and material breakdown prevention.

Materials we test

Materials we test

Our experts evaluate a wide range of insulation materials used in electronic devices and equipment, from cable insulation to protective barriers. We measure voltage breakdown points to ensure these barriers remain fit for purpose—even at peak voltage levels—helping you maintain safety and avoid costly failures.

- Electrical insulation barriers

- Cable telecommunications insulation

- Electronic device protection materials

- Product safety barriers

- Industrial equipment insulation

Methods And Solutions Offered

Methods And Solutions Offered

Our comprehensive testing approach includes sudden resistance change analysis, measuring sustained voltage tolerance, and guiding you in optimal material selection. We follow international standards to verify that your products meet required safety thresholds. By pinpointing the breakdown point, we help mitigate risk of material damage or human injury while expediting your product’s path to certification.

- Breakdown point identification

- Sustained voltage tolerance measurement

- Material selection guidance

- International standards compliance

- Safety validation protocols

Which Labs Offer This Service

Which Labs Offer This Service

Our 8,500-strong team operates from Materials Testing Services hubs across the world, providing global access to our capabilities with local, hands-on assistance no matter where you’re based.

Advanced Safety Validation

Advanced Safety Validation

We combine fast testing turnaround with thorough evaluations to ensure each insulation barrier effectively protects against dangerous current flow. Whether you’re verifying new materials or optimizing existing ones, our holistic approach helps you prevent electrical failures, maintain global safety standards, and deliver speed, convenience, and peace of mind to your development process.

Standards we test to and materials we test

Our Engaged Experts conduct dielectric testing to primary international standards, including:

American Society for Testing and Materials

- ASTM D149, ASTM D150, ASTM D877, ASTM D2520

American National Standards Institute/Society of Cable Telecommunications Engineers

- ANSI/SCTE 12, ANSI/SCTE 59, ANSI/SCTE 108

IPC – Association Connecting Electronics Industries

- IPC-TM-650 (Sections 2.5.5.1, 2.5.6, 2.5.6.3, 2.5.7, 2.5.7.1, 2.5.8)

- Electrical insulation materials

- Protective barrier materials

- Cable insulation materials

- Electronic device insulation

- Telecommunications insulation materials

(All tested for compliance with relevant international standards and unique customer specs.)

Your Challenges, Our Solutions

Reliable insulation performance

Understanding complex safety standards simplified

Material selection optimization

Protection from electrical current hazards

Why Choose Element

Global testing network

Industry standard leadership

Comprehensive solutions

Safety-first approach

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Electrical Testing Laboratories

Our electrical testing laboratories offer comprehensive testing and inspection services for components and materials subject to electrical currents.

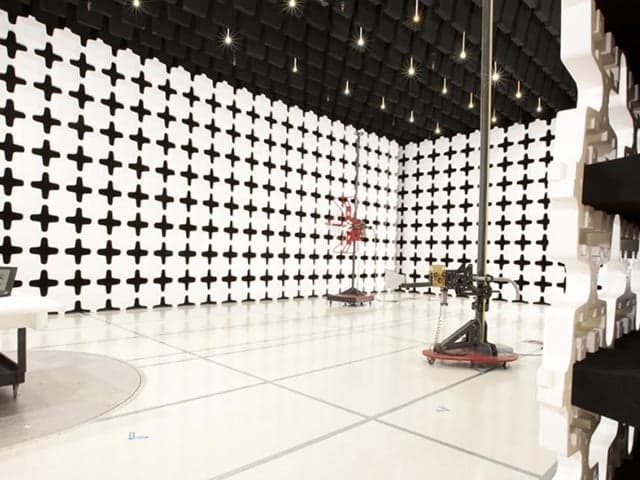

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.