Steiner Tunnel Testing

Accelerate your product’s market approval with Element's Steiner Tunnel Testing. Our expert team offers flexible, precise fire testing of building materials for global compliance. With both ceiling and floor-mounted options, we provide actionable data on flame spread and smoke development to ensure your products meet the strictest safety regulations. Partner with us for end-to-end fire testing solutions.

What is Steiner Tunnel Testing at Element?

Steiner Tunnel Testing measures the surface burning characteristics and smoke development of building materials under controlled fire conditions. At Element, we perform this test using recognized methods, including ASTM E84, UL 723, and CAN/ULC-S102/S102.2. Our facilities offer both ceiling-mounted and floor-mounted configurations to simulate real-world installation scenarios. This testing provides essential data on flame spread and smoke development, helping manufacturers meet safety regulations and achieve certification for their materials across global markets.

What Can Element Offer You For Steiner Tunnel Testing?

Components and materials we test

Components and materials we test

Element conducts Steiner Tunnel Testing on a wide range of materials, including wall finishes, ceiling materials, and flooring products. Whether for individual components or complete assemblies, our experts adapt testing for both ceiling-mounted and floor-mounted configurations, ensuring accurate evaluation in real-world installation conditions. Whether for individual components or complete assemblies, we assess new or existing materials' reactions to fire to support regulatory compliance and verify your material's performance.

Key tests offered

Key tests offered

We provide comprehensive Steiner Tunnel Testing to assess flame spread and smoke development in building materials. We can test to global standards, including ASTM E84 and UL 723 (ceiling-mounted) and CAN/ULC-S102 (Canadian ceiling-mounted equivalent). For flooring or materials that melt and drip, we conduct CAN/ULC-S102.2 (floor-mounted). Our testing delivers precise, reliable data to validate performance claims, meet North American and international regulations, and accelerate market approval from development to final certification.

Methods and solutions offered

Methods and solutions offered

Our experts use controlled testing methods to evaluate the surface burning characteristics of building materials. These include precise measurements of flame spread and smoke development through advanced photocell measurement systems, providing accurate and repeatable results. By simulating actual fire scenarios, we help you understand how your materials will perform in real installations, ensuring they meet safety standards and regulatory requirements for building material certification and compliance documentation.

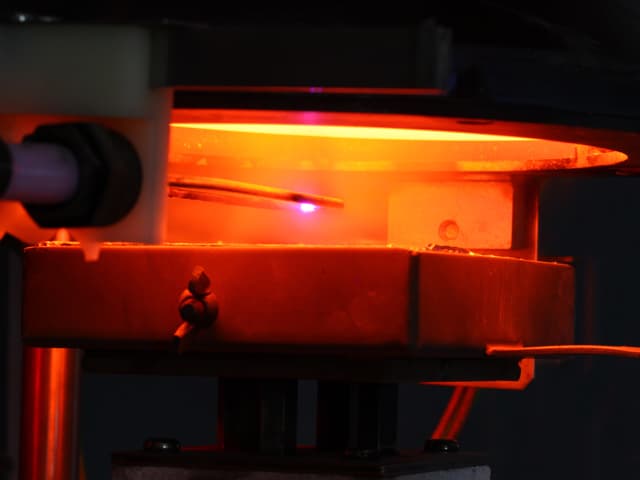

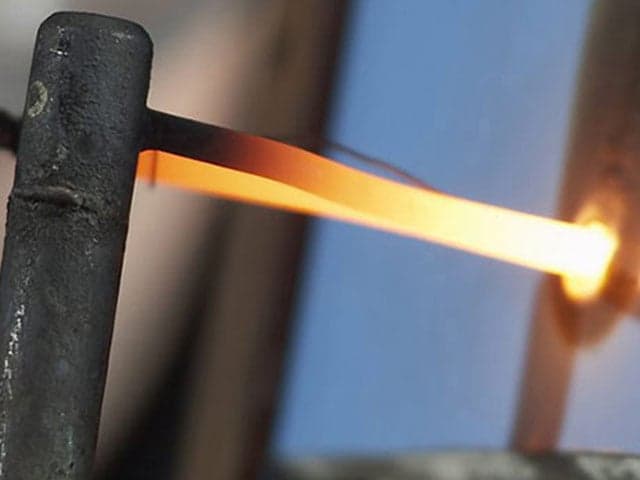

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art testing facilities feature large-scale horizontal furnace chambers, where test specimens are either ceiling-mounted or floor-mounted depending on the test. These chambers are equipped with specialized gas burners and advanced photocell measurement systems. Built-in observation windows enable precise tracking of flame progression throughout testing. Every aspect of our equipment is calibrated to deliver accurate, repeatable results that meet the most stringent requirements for building material certification and compliance documentation.

Comprehensive fire testing solutions

Comprehensive fire testing solutions

In addition to Steiner Tunnel testing, Element offers a suite of supporting fire safety tests, including cone calorimetry and radiant panel testing. These tests provide deeper insight into factors such as heat release rate and surface ignition, helping you understand how your materials perform under various conditions. By combining these test results with Steiner Tunnel (Surface burning characteristics testing) results, we offer a more complete picture of your material’s reaction-to-fire performance, ensuring compliance.

Standards we test to and components we test

- ASTM E84

- UL 723

- CAN/ULC-S102

- CAN/ULC-S102.2

- Wall finishes

- Ceiling materials

- Flooring products

- Surface coatings

- Interior assemblies

Your Challenges, Our Solutions

Remaining Compliant with Building codes

Achieving Fire safety validation

Difficult Cross-border approvals

Slow Product Development Cycles

Why Choose Element

Global Expertise

Precision Testing with Cutting-Edge Equipment

End-to-End Solutions

Adaptable Testing Methods

Frequently asked questions

What's the difference between ceiling and floor-mounted testing?

Ceiling-mounted testing evaluates materials installed facing downward, while floor-mounted testing specifically addresses flooring materials or products that may melt during standard testing.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Fire and Flammability Testing Services

Explore the range of fire & flammability testing services from Element. Ensure compliance with global labs, expert guidance & fast results.

Fire Testing Services

Ensure safety & compliance with Element's fire testing services. ISO-accredited labs, expert engineers & global reach for precise, reliable fire safety testing.

Cone Calorimetry Testing

Cone calorimetry testing for fire safety, heat release, smoke production, and compliance. Accurately assess material performance and fire risk for regulatory, development, and quality control purposes.

Reaction to Fire Testing

Get precise reaction to fire testing for compliance and safety. Our accredited labs deliver fire performance data to help you meet regulations and enhance product safety.

Radiant Panel Testing

The radiant panel test evaluates flooring materials' fire spread risk under intense radiant heat, supporting compliance with ASTM E648, NFPA 253, and ISO 9239 for safer buildings and transport.