Positive Material Identification (PMI) Testing Services

Need fast, reliable material verification without shipping delays or risk of damage? Element's Positive Material Identification (PMI) Testing Services deliver accurate alloy composition analysis both on-site and in our labs. We help you maintain compliance and avoid costly mix-ups while keeping your projects on schedule, wherever you operate.

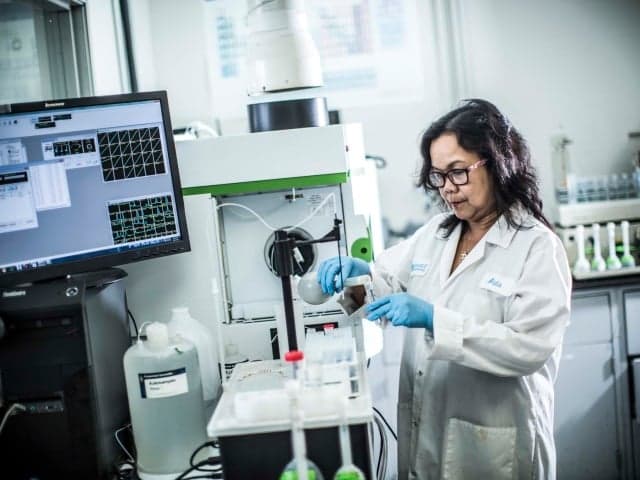

What is Positive Material Identification (PMI) Testing at Element?

PMI Testing is a non-destructive testing method used to verify the chemical composition of metals and alloys. Here at Element, we offer laboratory and portable XRF analysis solutions to confirm the types and percentages of elements in a material, helping you validate components at any stage of manufacturing without compromising their integrity.

What Can Element Offer You For Positive Material Identification?

Key tests offered

Key tests offered

- PMI Testing Services: Using XRF and OES technologies for precise chemical analysis of metals and alloys.

- Certified Alloy Verification: Official certification for alloy composition, ensuring compliance for safety-critical applications.

- Banned Elements Detection: Identifying restricted elements like lead and cadmium per ASTM E1476 standards.

- Mixed Batch Analysis: Ensuring consistency and eliminating material mix-up risks.

- On-Site Metallographic Analysis: Providing structural evaluations without damaging components.

Components and materials we test

Components and materials we test

We provide comprehensive testing for medium and high-alloy metals, including stainless steels, nickel alloys, aluminum, titanium, and copper alloys. Our services cover single-component verification, large batch analysis, and high-value or complex component evaluations.

Methods and solutions offered

Methods and solutions offered

For components that can’t be destroyed or shipped to a lab, our PMI testing can deliver invaluable results. Our XRF gun (X-ray fluorescence device) is a portable, non-destructive and cost-effective option for verifying alloy composition identifying general material types, and also evaluating materials in large batches.

Quality Assurance & documentation

Quality Assurance & documentation

We support your compliance needs with comprehensive documentation, traceability reports, and certified verification results. Our ISO 17025 accreditation ensures your testing meets the highest quality standards, backed by state-of-the-art equipment and rigorous procedures.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art XRF analyzers and OES (optical emission spectroscopy) technology deliver precise chemical analysis for both laboratory and portable testing requirements.

Which labs offer this service?

Which labs offer this service?

Element offers PMI testing both in advanced labs and on-site across the US and Europe. Key PMI labs include Aberdeen, Amsterdam, Doha, Hamburg, Huntington Beach, and New Berlin. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

Common Alloys:

- Stainless steels (304, 316, etc.)

- Inconel (625, 718, etc.)

- Super Duplex SS

Elements Commonly Verified:

- Titanium

- Chromium

- Zinc

- Cobalt

- Copper

- Iron

- Magnesium

- Molybdenum

- Nickel

Your Challenges, Our Solutions

Time-Critical Material Verification

Risk of Material Mix-ups

Testing Without Damage

Complex Testing Requirements

Why Choose Element

Global Reach, Local Support

Industry-Leading Expertise

Flexible, Non-Destructive Testing

Certified Alloy Verification

ISO17025

8+ global locations

XRF & OEStesting

ASTME1476

Frequently asked questions

Can PMI testing be performed on finished components?

Yes, our non-destructive PMI testing is ideal for finished components and items that cannot be damaged or shipped to a lab.

What elements can PMI testing detect?

PMI testing can detect most metal elements but cannot detect carbon. It's particularly effective for analyzing alloy composition and identifying restricted elements.

Do you provide any documentation with PMI testing?

Yes, we provide official alloy verification certificates and complete compliance documentation to support your traceability and safety-critical requirements.

What makes XRF analysis cost-effective?

XRF analysis provides rapid results without damaging materials, eliminating replacement costs and reducing operational downtime. It's particularly efficient for large batch testing.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

On-Site Metallographic Testing and Analysis

Element's on-site metallographic testing provides non-destructive analysis to assess material condition, detect defects early, and support informed decision-making in aerospace, oil & gas, and industrial applications.

Speak to our team of experts

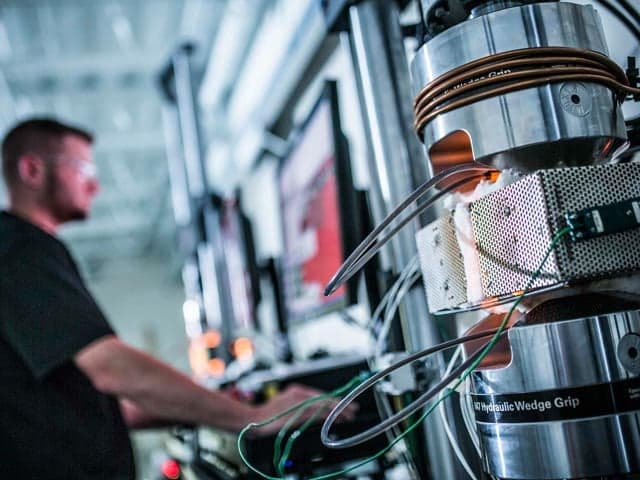

On-site PMI testing with portable XRF-analyzer

Shipping large, heavy, or sensitive materials to a laboratory can be time-consuming and costly. As part of On-site Metallographic Analysis, Element’s portable PMI testing using advanced XRF analyzers provides rapid results when fast project timelines or logistical constraints make lab testing impractical. Our team of PMI experts travels directly to your site, offering precise and non-destructive material verification that ensures your project stays on track without costly delays or interruptions to your operations.