Metallurgical Testing Services

From microstructure evaluations to comprehensive failure analysis, Element's globally accredited metallurgical testing services deliver precise insights that ensure product safety and reliability. Our expert team offers expedited options, on-site capabilities, and tailored solutions with designated points of contact throughout testing. We help you identify flaws, verify material quality, and meet industry compliance requirements efficiently.

What is metallurgical testing at Element?

Metallurgical testing examines the properties of metallic materials to determine if a particular metal is appropriate for its intended use. Used across a wide variety of industries, there are many different techniques, ranging from non-destructive to destructive testing; the type chosen typically depends on whether you are testing to prevent failure (requiring the product to remain intact), or after your part has already failed. Techniques aim to identify, confirm, and verify the properties of the metal through analysis and microscopic evaluations. Our accredited testing methods evaluate everything from grain structure to coating thickness, helping you identify flaws, check soundness, and confirm your materials meet the required specifications.

What can Element offer you for Metallurgical Testing Services?

Key tests offered

Key tests offered

Our comprehensive metallurgical testing services examine metals both above and below the surface. From grain size analysis to coating evaluations, our Engaged Experts use visual methods, sophisticated microscopy, and advanced instrumentation to detect both surface-level properties and subsurface characteristics.

Some of the metallurgical testing methods include but are not limited to:

- Alloy depletion

- Alpha case evaluation

- Austenite measurements

- Carburization/depth of decarburization

- Case depth

- Casting evaluation

- Chemical analysis

- Ferrite measurements

- Fractography

- Grain size measurements

- Inclusion content

- Intergranular corrosion

- Jominy testing

- Macroscopic evaluation

- Microstructure evaluation

- On-site metallography

- Particle analysis

- Passivation

- Photomicrography

- Pitting and crevice corrosion

- Plating and coating thickness

- Recast evaluation

- Replication metallography

- Scanning Electron Microscopy / Energy Dispersive Spectroscopy (SEM/EDS)

Tailored testing solutions for your peace of mind

From the moment we receive your inquiry, we identify your needs, and intended result usage, providing tailored solutions. Our flexibility extends to creating bespoke testing plans that align seamlessly with your requirements. Trust us to navigate the regulatory landscape, ensuring your materials comply with stringent industry standards for your peace of mind.

Customer-centric excellence in metal testing

Assuring you with timely booking, order acknowledgements, and designated points of contact throughout testing. Receive updates tailored to your preferences. We pride ourselves on swift turnaround times and offer expedited services when time is of the essence.

Methods and solutions offered

Methods and solutions offered

Our testing approach adapts to your specific needs, minimizing material loss when required and providing both field and laboratory solutions. We combine state-of-the-art technology with expert analysis to provide insights that matter for your specific industry and application.

Our experts use a variety of visual inspection techniques to evaluate the "big picture" of your materials - ensuring quality, integrity and properties meet specifications. For subsurface analysis, we employ high-powered Scanning Electron Microscopes (SEM) and optical microscopic equipment to detect characteristics invisible to the human eye.

On-site and laboratory capabilities include:

- On-site metallography for large or complex structures

- Replication metallography for non-destructive evaluation

- Macroscopic surface evaluation for detecting visible properties

- Microscopic subsurface analysis to find patterns and defects

- SEM/EDS advanced material characterization

- Complete failure analysis investigations

- Customer-specific testing protocols

- Alloy depletion analysis

- Casting evaluation

Macroscopic Evaluation

Our Engaged Experts use a combination of visual methods and instrumentation to detect surface-level metallic properties.

Macroscopic testing refers to any method performed using little to no magnification, or any other instrumentation used to examine surface level properties. These assessments focus on outward characteristics of metals and are often detectable by the naked eye. Our experts will use a variety of visual inspection techniques to evaluate the "big picture" - ensuring that the quality, integrity and properties of a material are what they should be.

Macroscopic evaluations are typically performed on finished products or treated metals, in addition to raw materials. Our macroscopic methods offer an efficient way to assess the overall condition of a material and can detect flaws or imperfections before a part goes into use or production.

Some of the tests that we offer include:

- Coating weight

- Contaminant and cleanliness

- Digital imaging

- Eutectic melting point

- Fractography

- Grain flow

- Macrostructure

- Passivation

- Surface discontinuities

- Surface roughness

- Visual inspection

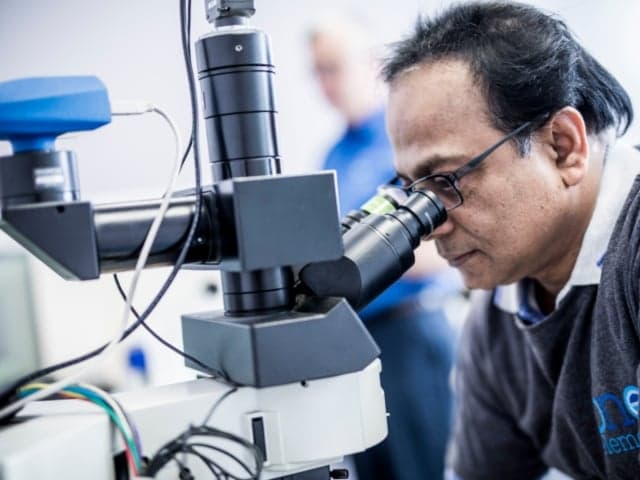

Microscopic Evaluation

Element's metallurgists use state-of-the-art technology to find patterns, defects and metallic characteristics below a material's surface.

Microscopic testing includes methods that use microscopic instruments to search for characteristics below the surface of a material, or those too small to be detected by the human eye alone. These types of evaluations are generally performed using a Scanning Electron Microscope (SEM), or other high-powered optical microscopic equipment. These methods apply when examining the subsurface of a material or a small section of a larger sample.

Some of the methods that we use include:

- Alloy depletion

- Banding

- Bradealloy

- Casting evaluation

- Case Depth (Carburization/Depth of decarburization)

- Coating thickness

- Constituent content

- Corrosion creep back

- Failure analysis

- Ferrite content

- Fiber length

- Fractography

- Grain Flow

- Grain size

- Inclusion content and severity

- Intergranular corrosion

- Intermetallic phase determination

- Microstructure evaluation

- Near-surface examination

- Nitriding

- Passivation

- Photomicrography

- Pitting and crevice corrosion

- Porosity

- Recast evaluation

- Replication metallography

- Scanning Electron Microscopy (SEM) / Electron Dispersive Spectroscopy (EDX)

- Volume fraction

- Weld Evaluation

On-Site Metallography

For larger or more complex projects that require on-site service, Element can perform a full suite of diagnostic and routine metallographic methods in the field.

While our labs can test a wide variety of material and component types in our facilities, there are some situations that require on-site testing. To accommodate this, we offer a comprehensive range of metallurgical test methods in the field for components and materials that are too large, too heavy, or too fragile to be transported to a lab. We offer the same quality testing and accurate results that you would get in one of our labs, and on-site services can often reduce test times for particularly urgent projects.

Some of the on-site services we offer include:

- Coating inspection

- Creep damage assessment

- Equotip hardness

- Ferrite content

- Fractography

- Microstructure evaluation

- Positive Material Identification (PMI)

- Thermal degradation

Materials and components we test

Materials and components we test

We test a wide range of metal materials and components across aerospace, automotive, energy, and manufacturing sectors. Our metallurgical testing services examine metals both above and below the surface to tackle your most challenging metallurgical questions.

Our laboratories are equipped to handle everything from small fasteners to large industrial components, examining both raw materials and finished products including:

- Ferrous materials: Carbon steels, alloy steels, tool steels, stainless steels, and cast irons

- Non-ferrous materials: Aluminum alloys, titanium alloys, nickel-based superalloys, copper alloys, and magnesium alloys

- Components: Fasteners (ASTM A490, ASTM A574, ASTM F606, ASTM F835), castings (ASTM A247, ASTM A800), welds (AWS D1.1, AWS D1.2, AWS D1.6), plated and coated components, and heat-treated parts

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories utilize the latest technology to deliver accurate, detailed metallurgical insights. Our equipment enables us to detect even the subtlest material characteristics and defects, providing you with comprehensive data about your metal components and materials. The advanced tools at our disposal allow for precise measurements and detailed analysis across all test types.

- Advanced scanning electron microscopy (SEM)

- Energy dispersive spectroscopy (EDS) systems

- State-of-the-art metallographic preparation equipment

- High-precision hardness testing instruments

- Digital imaging and analysis software

- Portable on-site metallography equipment

- Specialized corrosion testing apparatus

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing Services testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest Materials Testing Services hub is on our Locations Page.

Standards we test to and materials we test

American Society of Mechanical Engineers

- ASME B46.1, ASME IX, ASME Sec VIII, ASME V.6

ASTM International

- ASTM A90, ASTM A123, ASTM A247, ASTM A255, ASTM A262 , ASTM A342, ASTM A370, ASTM A428, ASTM A490, ASTM A561, ASTM A574, ASTM A604, ASTM A604 , ASTM A799, ASTM A800, ASTM A923, ASTM A923, ASTM A967

- ASTM B117, ASTM B137, ASTM B244, ASTM B276, ASTM B390, ASTM B487, ASTM B487, ASTM B489, ASTM B499, ASTM B504, ASTM B557, ASTM B571, ASTM B657, ASTM B659, ASTM B665, ASTM B748, ASTM B764, ASTM B767, ASTM B769, ASTM B962, ASTM B963

- ASTM C633, ASTM C692, ASTM C1617

- ASTM D610, ASTM D1186, ASTM D1400, ASTM D1654, ASTM D2247, ASTM D3359, ASTM D7091, ASTM D7091

- ASTM E3, ASTM E10, ASTM E18, ASTM E21, ASTM E45, ASTM E53, ASTM E92, ASTM E111, ASTM E112, ASTM E132, ASTM E190, ASTM E247, ASTM E290, ASTM E327, ASTM E340, ASTM E376, ASTM E381, ASTM E384, ASTM E407, ASTM E415, ASTM E466, ASTM E517, ASTM E562, ASTM E606, ASTM E646, ASTM E766, ASTM E883, ASTM E930, ASTM E975, ASTM E977, ASTM E1019, ASTM E1077, ASTM E1097, ASTM E1181, ASTM E1245, ASTM E1251, ASTM E1268, ASTM E1351, ASTM E1382, ASTM E1479, ASTM E1508, ASTM E1999, ASTM E2567

- ASTM F1089, ASTM F136, ASTM F1854, ASTM F2111, ASTM F2328, ASTM F67, ASTM F606, ASTM F788, ASTM F812, ASTM F835

- ASTM G17, ASTM G28, ASTM G36, ASTM G48, ASTM G64, ASTM G79, ASTM G87, ASTM G132

American Welding Society

- AWS A4.2, AWS B2.1, AWS D1.1, AWS D1.2, AWS D1.4, AWS D1.5, AWS D1.6, AWS D14.1, AWS D15.1, AWS D17.1, AWS D17.2

International Standards Organizations

- AS 7452, AS 7454, AS 7455, AS 7456, AS 7459, AS 7460, AS 7461, AS 7466, AS 7470, AS 7471, AS 7472, AS 7473, AS 7474, AS 7477, AS 7478, AS 7479

- BS ISO 3057, BS 131, BS 2633, BS 4449, BS 4871, BS 4872, BS 6286, BS 6744, BS 709, BS EN 287, BS EN 288, BS EN 1321, BS EN 10328, BS EN ISO 1463, BS EN ISO 2360, BS EN ISO 2639, BS EN ISO 4526, BS EN ISO 5173, BS EN ISO 5817, BS EN ISO 643, BS EN ISO 6509, BS EN ISO 9015, BS EN ISO 9016, BS EN ISO 9606, BS EN ISO 15614, BS EN ISO 15620, BS EN ISO 15630, BS EN ISO 17639

- DIN 50190, DIN 50600, DIN 50602, DIN 54150, DIN 54150, DIN EN 10328, DIN EN ISO 643, DIN EN ISO 1463, DIN EN ISO 17639, DIN EN ISO 2639, DIN EN ISO 2639, DIN EN ISO 3651, DIN EN ISO 3887

- EN 12797, EN 1321, EN 15614, EN 3683, EN 3684, EN ISO 3887, EN ISO 5817, EN-ISO 8249

- ISO 365, ISO 643, ISO 898, ISO 1463, ISO 1513, ISO 2360, ISO 2808, ISO 3057, ISO 3369, ISO 3651, ISO 4405, ISO 4406, ISO 4407, ISO 4967, ISO 4968, ISO 5817, ISO 5817, ISO 6157, ISO 6520, ISO 9602, ISO 9606, ISO 9227, ISO 13520, ISO 16232, ISO 17639, ISO 21809, ISO 26146

Aerospace Materials Specifications

- AMS 1595, AMS 2315, AMS 2315, AMS 2380, AMS 2643, AMS 4928, AMS 4965, AMS 4967, AMS 753, AMS W6858

SAE International

- SAE ARP 1341B, SAE J1061, SAE J121, SAE J122, SAE J123, SAE J403, SAE J404, SAE J417, SAE J419, SAE J422, SAE J423, SAE J425, SAE J439, SAE J448, SAE J78, SAE J81, SAE J933

Accreditations

Our accreditations demonstrate our commitment to quality and include but are not limited to:

- Bell

- Boeing

- Bombardier

- Cassna

- Embraer

- GE

- GE S400

Ferrous Materials

- Carbon steels

- Alloy steels

- Tool steels

- Stainless steels

- Cast irons

Non-Ferrous Materials

- Aluminum alloys

- Titanium alloys

- Nickel-based superalloys

- Copper alloys

- Magnesium alloys

Components

- Fasteners (ASTM A490, ASTM A574, ASTM F606, ASTM F835)

- Castings (ASTM A247, ASTM A800)

- Welds (AWS D1.1, AWS D1.2, AWS D1.6)

- Plated and coated components

- Heat-treated parts

Your Challenges, Our Solutions

Quality verification for peak performance

Complex metallurgical insights made clear

Time-critical results delivered promptly

Standards compliance simplified effectively

Why Choose Element

Specialized metallurgical expertise

Comprehensive metallographic capabilities

Advanced metallurgical technology

Flexible testing approaches

But don't just take our word for it

See what others want to say about partnering with Element

Frequently asked questions

What is on-site metallography and when should it be used?

On-site metallography brings our testing capabilities directly to your location, ideal for components too large, too heavy, or too fragile to transport or when equipment cannot be taken out of service. Our field experts perform a complete range of diagnostic and routine metallographic methods directly at your facility, minimizing downtime while providing critical material insights. On-site services can often reduce test times for particularly urgent projects.

Customer-centered service approach

From project initiation to final reports, we make working with us straightforward. We provide timely booking, order acknowledgments, and designated points of contact throughout testing. Receive quick updates tailored to your preferences, with swift turnaround times and expedited services when time is critical.

Our experts identify your specific needs and intended result usage from the outset, creating bespoke testing plans that align with your requirements. We navigate the regulatory landscape for you, ensuring your materials comply with stringent industry standards.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

In-Situ Replication Metallography and Replica Testing

Prevent equipment failures with Element's in-situ replication metallography - non-destructive testing that assesses material conditions while your operations continue. Expert analysis for high-temperature equipment. Request testing today

On-Site Metallographic Testing and Analysis

Element's on-site metallographic testing provides non-destructive analysis to assess material condition, detect defects early, and support informed decision-making in aerospace, oil & gas, and industrial applications.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Compression Testing

Element's compression testing services evaluate material strength, durability, and performance under load, helping you reduce failure risk, meet standards, and improve product development. Learn More.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.