Steel Testing Services

Your steel products need to meet rigorous quality standards without delaying market launch. Element's reliable steel testing services help validate material performance, prevent costly failures, and support your regulatory compliance. Leverage specialized expertise to aid your transition to lower-carbon production, while maintaining competitive advantage in a demanding industry.

What is Steel Testing at Element?

Steel testing services cover a wide range of methods to evaluate the properties, quality, and integrity of steel materials and structures, ensuring they meet safety and performance standards. These tests can be destructive or non-destructive and include mechanical, chemical, and metallurgical analyses.

At Element, we provide comprehensive testing services specifically tailored to steel manufacturers and fabricators. Our laboratories perform everything from standard metallurgical and mechanical testing to advanced fracture toughness analysis, supporting your steel products throughout their lifecycle.

What Can Element Offer You For Steel Testing?

Key tests offered

Key tests offered

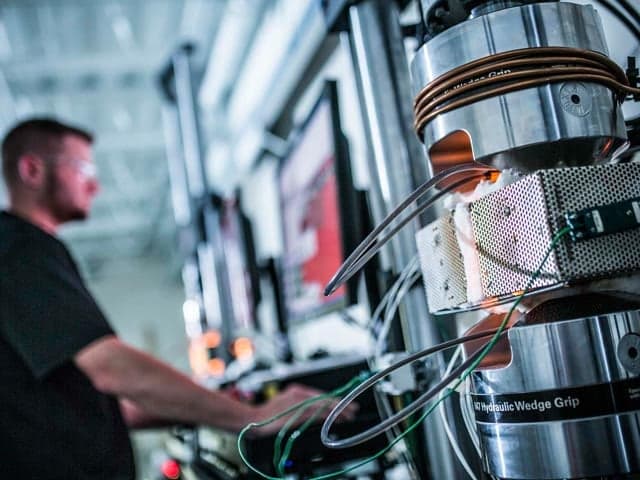

Address your quality assurance needs with our comprehensive testing suite. Element offers mechanical and destructive testing, non-destructive testing (NDT), metallurgical testing, corrosion testing, chemical analysis, and failure analysis. Our advanced capabilities include fracture toughness testing, drop weight tear testing (DWTT), and dynamic tear testing to evaluate material behavior under various conditions.

Materials we test

Materials we test

From raw steel production to finished components, Element tests across your entire supply chain. Our laboratories analyze structural steel, pipeline materials, pressure vessels, automotive components, and high-performance alloys. We understand the unique requirements of each application, so your steel meets industry-specific standards and performs reliably under real-world conditions.

- Structural steel

- Pipeline and pressure vessel steels

- Automotive steel components

- Energy sector steel applications

- High-performance alloy steels

Methods and solutions offered

Methods and solutions offered

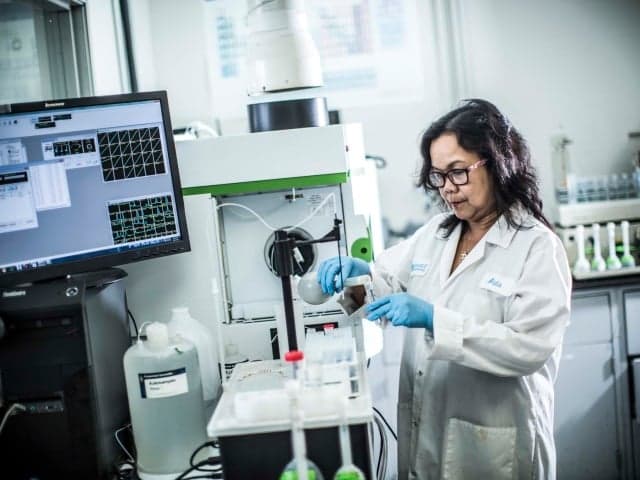

Meet compliance requirements efficiently with Element's tailored testing approaches. From standard 3.2 witnessed test schedules to customized testing programs for specialized applications, we adapt our methods to your specific needs. Our hydrogen testing solutions support your transition to lower carbon emissions, while our failure analysis helps prevent future issues in your steel products and extends service life through detailed evaluation of potential failure modes.

- 3.2 witnessed test schedules

- Customized testing programs

- Hydrogen testing for emissions reduction

- Failure analysis and prevention

- Material performance evaluation

Cutting-edge equipment we use

Cutting-edge equipment we use

Element's laboratories house state-of-the-art equipment for precise, reliable results. Our advanced testing capabilities for fracture toughness, hydrogen effects, and corrosion analysis use the latest technology to deliver accurate measurements. This investment in cutting-edge equipment provides you with high-quality data to support your materials engineering decisions and helps identify potential issues before they impact production or field performance.

Which labs offer this service

Which labs offer this service

Our extensive network of steel industry services operates across Europe, North America, and Asia, delivering the same high standards regardless of location. This global presence means we can support your operations wherever they are, providing local expertise with international consistency and reducing logistical challenges when testing materials from global supply chains. Find your nearest lab on our Locations page.

Your Challenges, Our Solutions

Efficient quality verification

Compliance slowdowns

Achieving market speed with quality assurance

Carbon reduction without performance compromise

Why Choose Element

Steel industry testing pioneers

Metallurgical testing excellence

Fracture toughness specialists

Hydrogen effects expertise

Supporting sustainability transitions

Accelerate your transition to greener steel production with Element's specialized hydrogen testing. Our Engaged Experts have extensive experience analyzing hydrogen effects on steel, including corrosion and permeation. This expertise directly supports your efforts to reduce CO2 emissions and transition from carbon-based energy sources to hydrogen alternatives while maintaining the structural integrity and performance characteristics your applications demand.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.