Flammability Testing of Plastics

Ensure your plastic materials meet global fire safety standards with Element’s expert flammability testing of plastics. From UL 94 to ASTM, ISO, and BS EN, we help you achieve regulatory compliance across North America, the UK, and Asia. Get precise, accredited data to fast-track approvals, reduce risk, and build market confidence - so your products perform safely.

What is Flammability Testing of Plastics at Element?

Many plastic materials burn when ignited, and their flammability properties can make them a dangerous accelerant in a fire situation. Flammability testing of plastics assesses their behavior when exposed to fire or heat sources under controlled conditions.

At Element, our testing helps you understand how your materials will perform and meet applicable safety standards. We provide comprehensive testing services to determine fire classification, burning rates, ignition propensity, and heat release characteristics of your plastic materials. Our goal is to ensure your plastics are fully assessed to applicable national and international industry standards, such as UL 94, for their flammability and heat-related properties, and that they are safe for their end application.

What Can Element Offer You For Flammability Testing of Plastics?

Materials We Test

Materials We Test

Element can test a wide range of plastic materials across various industries, from electronic device components to construction materials. Our laboratories evaluate everything from thin films to thick plastic sections, foamed plastics to composites. Whether you need testing for appliance housings, insulation materials, vehicle interiors, rail, marine or building products, we deliver precise data on flammability characteristics to support your compliance needs and help you meet safety requirements for your end application.

Key Tests Offered

Key Tests Offered

Our comprehensive testing capabilities assess the full spectrum of flammability characteristics your plastic materials need to succeed in the marketplace. We conduct vertical and horizontal testing to assess burning rates and test for ignition propensity, ignition temperature (in the air), and oxygen index. These evaluations provide critical insights into how your materials will respond in fire situations, helping you make more informed decisions about material selection and installation.

- UL 94 vertical burn tests (V, 5VA, 5VB, VTM classifications)

- UL 94 horizontal burn tests (HB, HBF classifications)

- Oxygen Index Test (BS EN ISO 4589-2:2017 & BS EN ISO 4589-3:20)

- Surface Spread of Flame Test (BS 476: Part 7:1997)

- Ignitability Testing (BS 476 Part 12:1991, BS EN ISO 11925-2:2020, BS ISO 11925-3:1997)

- Single Burning Item (SBI) Test (BS EN 13823:2020)

- Rail Testing EN 45545-2

- IMO Fire Test Procedures Code

The information you gain from UL 94 tests provides:

- An indication of the material's potential acceptance concerning a particular application

- Material classification to relevant industry standards

- Material development data

- Quality control assurances

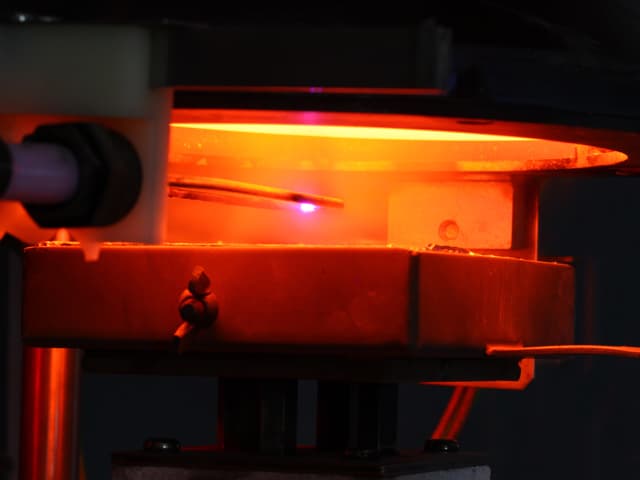

Cone Calorimeter screening tests

Gain valuable development insights with this advanced testing, which provides critical data on your material's heat release rate, smoke production, and ignition behavior during development phases. Testing plastics through the Cone Calorimeter delivers insights into flammability properties that are crucial for making informed material selection choices for your final application, helping you develop safer products that meet regulatory requirements from the earliest stages.

- Early-stage material assessment

- Comparative analysis of material alternatives

- Detailed heat release characterization

- Smoke production quantification

- Material optimization guidance based on performance data

Methods And Solutions Offered

Methods And Solutions Offered

Our approach to flammability testing combines technical precision with customer-focused service. We work with you to determine the most appropriate test methods based on your material type and end-use application. The information you gain from our testing provides an indication of your material's potential acceptance for particular applications, classification to relevant industry standards, and quality control assurances, helping you navigate regulatory requirements with confidence.

- Material classification to relevant industry standards

- Comprehensive data for R&D

- Quality control assurance testing

- Testing programs across multiple international standards

- Customized testing protocols for specific applications

- Standardized testing for regulatory compliance

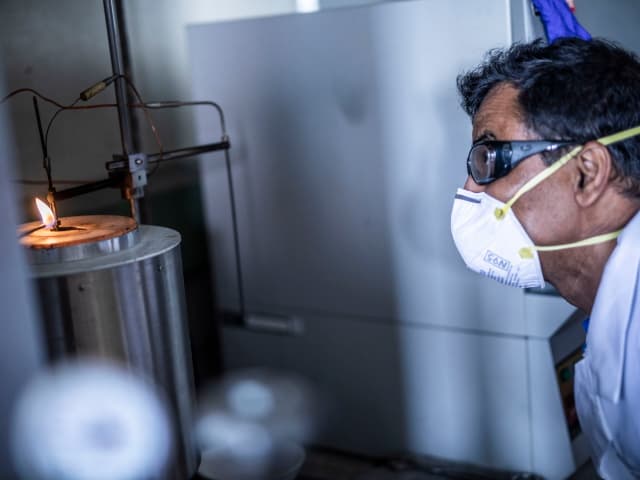

Oxygen Index Test (BS EN ISO 4589-2:2017 & BS EN ISO 4589-3:20)

This test measures the minimum oxygen concentration needed to support sustained ignition, indicating how flammable a material is. A series of specimens are tested at different oxygen levels, and the lowest concentration that sustains burning is recorded as the oxygen index value.

Surface Spread of Flame Test (BS 476: Part 7:1997)

This test assesses how flames spread across the surface of a material without necessarily igniting its core. It is used to classify plastics and surface materials based on their flame spread performance, helping evaluate their potential behavior in real fire situations. The test is primarily used for wall and ceiling linings.

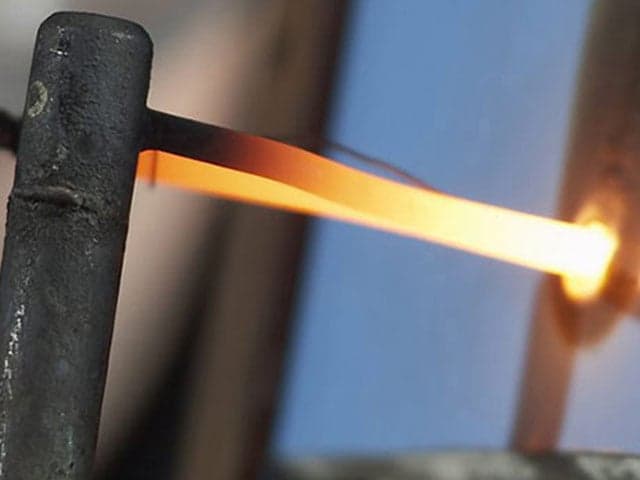

Ignitability Testing (BS 476 Part 12:1991, BS EN ISO 11925-2:2020, BS ISO 11925-3:1997)

These tests determine how easily a material, composite, or assembly ignites when exposed to direct flames. The test setup includes multiple ignition sources that simulate real-life fire scenarios. Observations include sustained ignition, flaming debris, and whether fire spreads to the edges of the specimen. However, this test does not assess flame spread.

Single Burning Item (SBI) Test (BS EN 13823:2020)

This test evaluates a material’s heat release, flame spread, and smoke production when exposed to a burning object. The results help determine how a material contributes to fire growth and how quickly it could cause a fire to spread. Understanding these properties is essential for ensuring fire safety in buildings.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Access industry-leading testing capabilities with Element's state-of-the-art equipment. Our fire testing laboratories feature advanced Cone Calorimeters—the most widely used apparatus for determining potential heat evolution in a fire. As part of our flammability testing of plastics, we offer screening and material development tests through the Cone Calorimeter, providing critical insights into your material's flammability properties and helping you make more informed material selection decisions.

- Cone Calorimeter testing apparatus

- Vertical and horizontal burn test chambers

- Oxygen index testing equipment

- Specialized flammability assessment chambers

- Heat and smoke measurement systems

Which Labs Offer This Service

Which Labs Offer This Service

Element's fire testing laboratories across North America provide accessible, local testing with consistent global standards. For European testing needs, our group company Warringtonfire are fire and flammability specialists offering reaction to fire testing such as oxygen index tests and Single Burning Item (SBI) tests. With our combined expert network across multiple continents, you get seamless access to flammability testing expertise wherever your business operates.

- Multiple fire testing laboratories across North America

- Facilities in Europe, including Warrington, UK

- Global network of fire testing experts in The Middle East, Australia, Asia, and Africa

- Local support with international capabilities

- Consistent testing standards across all facilities

Standards we test to and materials we test

General Flammability and Fire Testing Standards

- UL 94

- ASTM C1166

- ASTM D3675

- ASTM E162

- ASTM E648

- ASTM E662

- ASTM E970

- ASTM E1354

Oxygen Index and Ignitability Standards

- BS EN ISO 4589-2:2017 (Oxygen Index Test)

- BS EN ISO 4589-3:20 (Oxygen Index Test)

- BS 476 Part 12:1991 (Ignitability Testing)

- BS EN ISO 11925-2:2020 (Ignitability Testing)

- BS ISO 11925-3:1997 (Ignitability Testing)

Flame Spread and Reaction to Fire Standards

- BS EN 13823:2020 (Single Burning Item (SBI) Test)

- ISO 5660 (Cone Calorimeter)

- ISO 5658 (Surface Flammability)

- ISO 5659 (Smoke Generation)

- Rail Testing EN 45545-2

- IMO Fire Test Procedures Code

Industry-Specific Fire Safety Standards

- Boeing BSS 7239 (Aerospace Industry)

- Bombardier SMP 800-C (Rail Industry)

- MVSS 302 (CMVSS 302/FMVSS 302) (Automotive Interior Flammability)

Electronic and appliance materials

- Plastic device housings

- Appliance components

- Electronic enclosures

- Plastics used in devices

Construction materials

- Plastic surface materials

- Foamed plastics for insulation

- Spray foam insulation

- Wall and ceiling plastic linings

- Plastic materials used in buildings

Transportation materials

- Plastics used in transportation vehicles

- Aircraft cabin plastic materials

- Automotive interior plastic components

- Rail vehicle plastic components

- Mass transit interior plastic materials

- Marine materials

Decorative materials

- Decorative plastic materials

- Furniture plastic components

- Interior design plastic elements

- Display and signage plastics

- Exhibition and retail plastic materials

Your Challenges, Our Solutions

Complex regulations simplified

Predicting real fire behavior

Selecting the best plastic materials

Development cycles accelerated

Why Choose Element

Industry-leading flammability expertise

Comprehensive plastic testing solutions

Advanced fire testing equipment

Global plastic testing capabilities

20+fire safety standards assessed

4+continents with accredited labs

5+UL 94 classifications tested

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Flammability Testing Services

Ensure product safety with Element’s expert-led Flammability Testing Services. Vertical & Horizontal testing. Meet industry standards, reduce risk, and get to market faster.

Oxygen Index Testing

Element's ASTM D2863-17a oxygen index testing measures the minimum oxygen concentration required for combustion in materials. Get precise, industry-compliant testing for polymers, cables, fabrics, and more.

Furniture Flammability Testing

Element provides accredited furniture flammability testing to confirm compliance with major fire safety standards, helping manufacturers meet regulatory requirements and deliver safe, market-ready products.

Textile Flammability Testing

Element's textile flammability testing helps ensure compliance with safety standards and flammability requirements to manufacture safer products and reduce risks of burn injuries. Learn more.

Cone Calorimetry Testing

Cone calorimetry testing for fire safety, heat release, smoke production, and compliance. Accurately assess material performance and fire risk for regulatory, development, and quality control purposes.

Reaction to Fire Testing

Get precise reaction to fire testing for compliance and safety. Our accredited labs deliver fire performance data to help you meet regulations and enhance product safety.