Accelerated Weathering Testing Services

Transform your product development timeline with accelerated weathering testing that delivers years of environmental exposure data in weeks. You'll gain critical insights into material durability and performance, protecting your products against premature failures and meeting global compliance standards.

What is Accelerated Weathering Testing at Element?

Accelerated weathering testing simulates long-term environmental exposure in compressed timeframes. At Element, we replicate real-world conditions through specialized equipment and testing protocols, helping you understand how your materials and products will perform over their entire lifecycle without waiting years for natural weathering data.

What Can Element Offer You For Accelerated Weathering Testing Services?

Key tests offered

Key tests offered

Element offers a full range of accelerated laboratory testing services, including but not limited to:

- Salt spray (neutral (NSS), acetic acid (AASS), and copper accelerated (CASS)

- UV testing which can include pure UV, set temperature, condensation, and water spray control

- Xenon which can include pure xenon, humidity, temperature control

- Xenon Arc - ideal for applications where high-quality finishes in paints and coatings are crucial, especially when facing elevated levels of UV degradation

- Carbon Arc - evaluates a product's resistance to deterioration in electrical, mechanical, and optical properties when exposed to light and heat

- Climate chambers to control temperatures and humidity and can be set to various levels and ramp rates

- Cathodic disbondment both impressed and sacrificial anode

- Immersion in various fluids

- Pre-fire testing accelerated weathering (Hydrocarbon and Cellulosic)

- Cryogenic exposure

- Thermal exposure

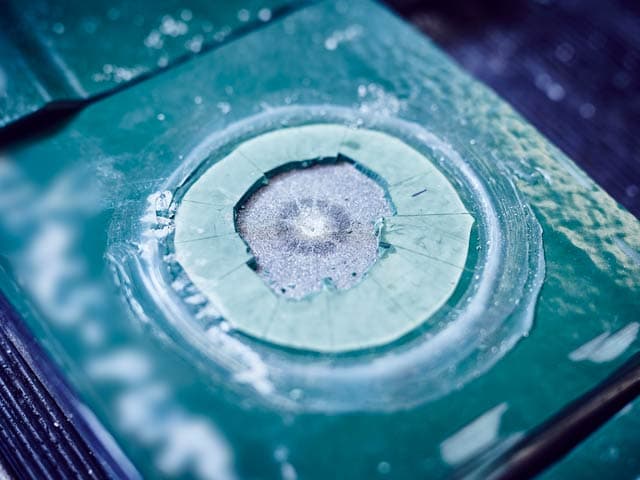

- Paint and Coating Testing

- Salt Spray

- Salt Fog

- Corrosion Testing

- Chemical resistance

- High temperature, and cryogenic exposure

Components & materials we test

Components & materials we test

From automotive components to high-performance coatings, we test materials across multiple industries. Our expertise spans paint systems, sealants, fabrics, polymers, and specialized industrial coatings, giving you comprehensive insights into material performance and longevity.

Methods and solutions offered

Methods and solutions offered

Our testing programs combine multiple environmental factors to deliver comprehensive performance data. We create custom testing protocols aligned with your specific requirements, supported by mechanical, analytical, and electrochemical testing capabilities.

Cutting-edge equipment we use

Cutting-edge equipment we use

Element offers specialized environmental equipment such as:

- Advanced UV cabinets

- Salt spray chambers

- Environmental control systems

- Xenon arc testing units

- Carbon arc testing equipment

- Climate chambers with precision control

- Specialized immersion testing equipment

Which labs offer this service

Which labs offer this service

Our Amsterdam facility serves as our center of excellence for weathering testing, offering comprehensive capabilities including mechanical, analytical, and electrochemical testing. Additional fully equipped laboratories across the United States, Middle East, and Asia provide convenient access to our complete range of accelerated weathering services, supporting your testing needs with local expertise backed by global resources. Find your nearest Product Qualification Testing hub on our Locations Page.

Standards we test to and materials we test

Element provides accelerated weathering testing to many common industry standards, including those shown below, as well as custom specifications:

- AMPP

- AMPP TM 21612

- American Society for Testing & Materials

- ASTM C793-05, ASTM D1171, ASTM D1499, ASTM D2126, ASTM D2247, ASTM D2565, ASTM D4329, ASTM D4355, ASTM D4459, ASTM D4587, ASTM D4674, ASTM D4798/D4798M, ASTM D5071, ASTM D5208, ASTM D5427, ASTM D5894, ASTM D6521-13, ASTM D6551, ASTM D6695, ASTM D7869, ASTM E408, ASTM E773, ASTM F1980, ASTM F1980-16, ASTM G147, ASTM G151-55

- British European Standards

- BS 7976-2, BS EN 1062-11, EN 16623

- Defence Standards

- MIL STD 810E, MIL STD 810F

- EAD

- EAD 350402-00-1106, EAD 350140-00-1106

- General Motors Company Specifications

- GM9327P, GMW 14124

- International Organization for Standardization

- ISO 105 B02, ISO 105 B06, ISO 11507, ISO 12944-6, ISO 12944-9, ISO 16474-1, ISO 16474-3, ISO 20340, ISO 4892-2, ISO 4892-3, ISO 15711, ISO 19277, ISO 21809-1, ISO 21809-2, ISO 21809-3, ISO 11503

- NACE

- NACE TM0304, NACE TM0404, NACE TM 0185

- NORSOK

- NORSOK M-501

- OEM Specifications

- FORD FLTM BO 116-01, Honda HES D6601, NISSAN NES M0135, Peugeot PSA D47 1431, Toyota TSH1585G, VW PV1303

- Society of Automotive Engineers

- SAE J1885, SAE J1960, SAE J2020, SAE J2412, SAE J2527, SAE J575

- VGBE

- VGBE-S-021-02-2023-05

- Automotive: Components, finishes, interior materials

- Industrial: Paints, coatings, sealants

- Construction: Building materials, weatherproofing systems

- Consumer Products: Textiles, plastics, polymers

- Marine: Protective coatings, materials

- Electronics: Component housings, protective materials

Your Challenges, Our Solutions

Accelerating development timelines

Preventing product failures before launch

Meeting global standards with ease

Complete environmental performance data

Why Choose Element

Protection Against all Environmental Factors

Create Better, More Durable Products

Bespoke Solutions by Experts

Coatings Approvals and Performance Specialists

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Oil and Gas Corrosion Testing Services

Element's oil and gas corrosion testing identifies material vulnerabilities, supports compliance, and prevents failures through advanced simulation, predictive modeling, and testing in extreme environments.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Mechanical and Physical Testing of Coatings

Verify your coating performance, durability, compliance and damage resistance with Element's mechanical and physical testing. ISO 17025 certified testing for actionable insights. Learn More.

Carbon Arc Testing

Element provides carbon arc testing for plastics, paints, and coatings, using advanced methods to assess material durability against sunlight and moisture.

Ultraviolet Exposure & UV Testing Services

Element's UV testing services simulate sunlight exposure to assess material durability. Gain critical insights into degradation, improve product longevity, and meet industry standards with precise, lab-controlled testing.

Xenon Arc Testing

Validate material durability faster with our xenon arc testing. Accelerate product development and prevent failures with UV and weathering simulation.