Battery Safety and Abuse Testing

Protect your customers and your brand with Element's comprehensive battery safety and abuse testing to identify potential safety issues before market release. You'll receive actionable data on battery performance under real-world and extreme conditions, helping you navigate complex regulations and build consumer confidence. By partnering with our industry-leading facilities – the largest in North America, you’ll launch safer, more reliable battery-powered products faster.

What is Battery Safety and Abuse Testing at Element

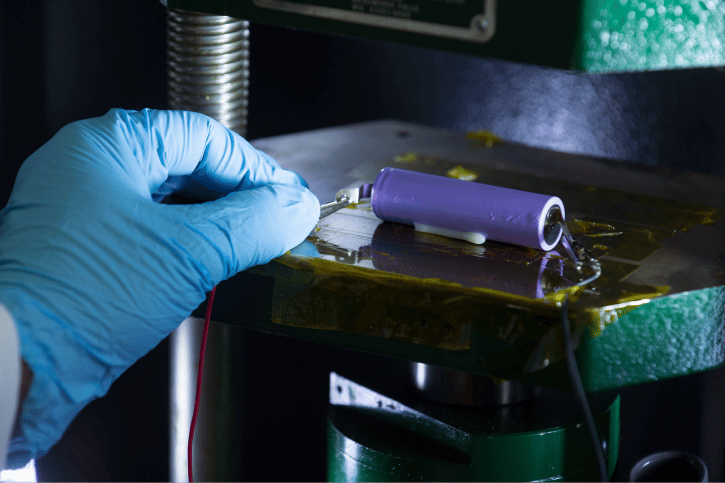

Battery Safety and Abuse Testing evaluates how batteries respond to various conditions to verify their safety and reliability. Safety testing focuses on ensuring batteries function properly during normal operation and reasonably foreseeable misuse, meeting industry standards and regulatory requirements. Abuse testing goes further, deliberately subjecting batteries to extreme conditions - like severe mechanical damage or electrical overloads - to evaluate failure modes and safety mechanisms.

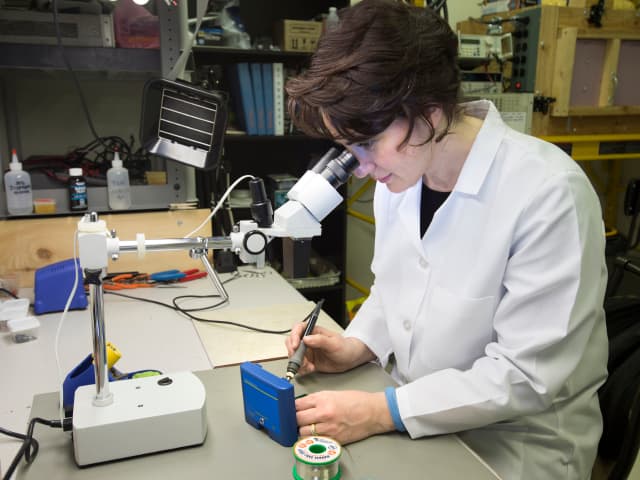

At Element, we provide comprehensive battery safety and abuse testing services across multiple industries, examining abuse responses in both small and large format batteries with various cell types and chemistries. With incidents of dangerous battery failures becoming an industry-wide concern and focus of public attention, our testing helps identify potential issues early, protecting consumers and your brand reputation.

What can Element offer you for Battery Safety and Abuse Testing?

Key tests offered

Key tests offered

Element provides comprehensive safety and abuse testing including internal short circuit evaluation, overcharge testing, crush and impact assessment, nail penetration simulation, and thermal runaway propagation analysis. Our advanced capabilities subject your batteries to environmental, mechanical, and electrical stress conditions - including intentional stress conditions far beyond normal operating parameters. This gives you valuable data about how your batteries perform in extreme scenarios and helping you identify potential safety issues early in development.

- Internal short circuit testing

- Overcharge evaluation

- Crush and impact assessment

- Nail penetration simulation

- Thermal runaway propagation analysis

Products and components we test

Products and components we test

You need a testing partner who can handle every aspect of your battery testing requirements. Element tests batteries for electric (EV) and Hybrid-electric (HEV) vehicles, industrial equipment, medical devices, consumer electronics, aerospace applications (EVTOL), and outdoor power products. Our specialized facilities evaluate various cell types and chemistries across industries, providing you with comprehensive data to support safety claims and regulatory compliance. We examine both small-format cells and large battery assemblies to give you complete confidence in your products.

- Lithium-ion batteries and cells

- Nickel system batteries

- Secondary cells with alkaline electrolytes

- Secondary cells with non-acid electrolytes

- Portable sealed batteries

Methods and solutions offered

Methods and solutions offered

You need clear data to make critical safety decisions. As your single-source provider for comprehensive battery safety and abuse testing, we apply standardized and customized test protocols to identify potential issues early in development. We evaluate batteries under conditions that far exceed normal operating parameter, providing reliable performance data and safety assessments that help meet regulatory requirements. This approach helps you design safer, more reliable products that perform well even in extreme environments—making them more attractive to customers.

- Abuse response analysis

- Safety parameter evaluation

- Early hazard identification

- Design issue detection

- Certification support

Battery abuse testing typically falls into four categories, but tests can be combined to mimic specific conditions. Test methods or protocols can be customized to meet your needs:

- Environmental stress: including very high or very low temperature (down to -40⁰C and up to +300⁰C), humidity, high altitude or vacuum, overpressure, salt or freshwater immersion, thermal splash shock, thermal shock, hot oven, or accelerated rate calorimetry.

- Mechanical stress: including vibration, mechanical shock, crushing, nail penetration, impact, free fall, bend testing, and end crushing.

- Electrical stress: including over-voltage, under-voltage, over-current during charge, short circuit during discharge, and forced discharge.

- Intentional thermal runaway testing

Cutting-edge equipment we use

Cutting-edge equipment we use

You need clear data to make critical safety decisions. As your single-source provider for comprehensive battery safety and abuse testing, we apply standardized and customized test protocols to identify

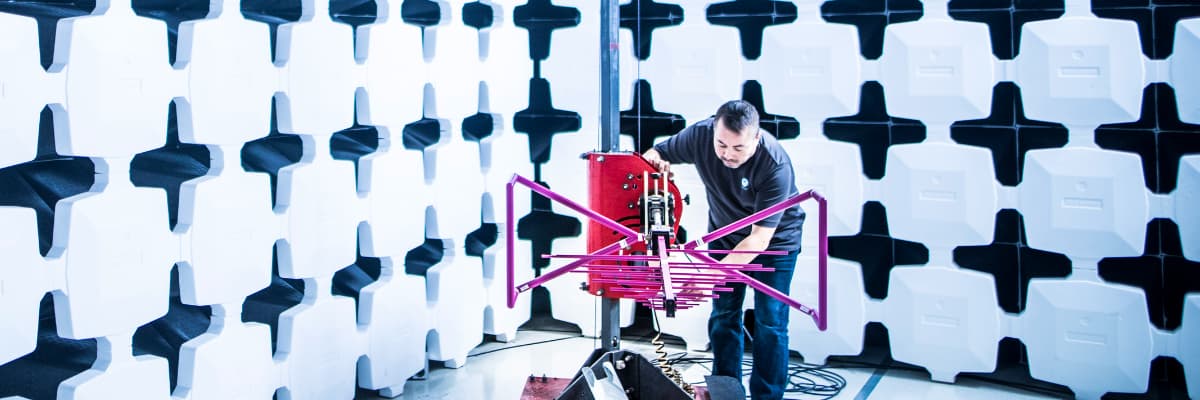

Our global network of purpose-built facilities offers the largest battery testing capacity in North America, delivering accurate and comprehensive results that you can trust. Our state-of-the-art equipment allows us to simulate real-world conditions and extreme abuse scenarios with exceptional accuracy, giving you confidence in your battery's safety performance.

- Specialized testing chambers

- Thermal monitoring systems

- High-precision measurement tools

- Advanced data collection technology

- Abuse testing facilities

Which labs offer this service

Which labs offer this service

With battery testing labs across the US, Europe and South Korea, we provide global access to our expert capabilities. Find your nearest connected technologies testing hub on our Locations Page.

Standards we test to and products we test

Battery types

- Lithium-ion batteries and cells

- Nickel system batteries

- Secondary cells with alkaline electrolytes

- Secondary cells with non-acid electrolytes

- Portable sealed secondary cells

- Household batteries

- Commercial batteries

Applications

- EV and HEV battery systems

- Industrial equipment power sources

- Medical device power systems

- Consumer electronics batteries

- Aerospace (EVTOL) battery systems and components

- Outdoor power product batteries

Your Challenges, Our Solutions

Battery safety risks

Complex global regulatory requirements

Designs weaknesses causing delays

Recalls and incidents damaging trust

Element Experts at your service

Why Choose Element

Complete battery safety solution

Industry-leading testing capacity

Small and large format expertise

Advanced abuse response analysis

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Battery Testing Services

Accelerate your product launch with Element's battery testing services. Superior safety, compliance, and performance data, custom protocols & real-time results. Learn More.

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Battery Performance Testing & Competitive Benchmark Testing

Element's battery performance testing and competitive benchmark testing delivers accurate, real-world data on capacity, endurance, and discharge rates to help refine products, reduce risk, and support competitive market positioning.

Lithium Battery Testing and Certification Services

Ensure safety, performance, and regulatory compliance with comprehensive lithium battery testing. Element's advanced laboratories can test lithium metal and lithium-ion batteries for any application, from medical devices to electric vehicles.