Macro Etching

Identify critical material defects before they become costly failures. Element's Macro Etching services reveal hidden issues in metals, from nickel and titanium alloys to stainless steel and beryllium, helping you maintain component integrity and regulatory compliance. Our highly trained metallurgists work directly with you to determine the most effective testing methods for your specific materials, providing reliable, accurate results through specialized non-destructive evaluation that ensures your safety-critical parts meet the highest performance standards.

What is Macro Etching at Element?

Macro Etching is a non-destructive testing method that uses a mixture of chemicals and compounds to remove the top layer of a sample, exposing grain structures and internal features for detailed evaluation. At Element, our highly trained metallurgists apply this specialized technique for both cleaning and inspection of various metals including nickel and titanium-based alloys, enabling you to evaluate grain size and flow, detect material segregations (like white spots or "freckles" in nickel alloys), identify overheat conditions, and verify your materials are fit for purpose.

What Can Element Offer You For Macro Etching?

Key Tests Offered

Key Tests Offered

Our Macro Etching services reveal crucial material characteristics that impact your component performance and safety. We examine material features that can be observed without microscopes or with very low magnification (grains must be large for grain boundaries to be visible), including:

- Grain size and grain boundaries evaluation

- Banding identification

- Surface discontinuities detection

- Fractures and defects analysis

- Macro structure examination

- Forging defects identification

- Material segregations assessment (including white spots, “freckles,” and gross material segregations in titanium)

- Overheat condition identification

Methods And Solutions Offered

Methods And Solutions Offered

Element provides comprehensive chemical etching processes tailored to your specific material requirements, with turnaround times that meet your project deadlines. We work with you to determine the best etching methods for your projects, delivering reliable, accurate results to verify your materials are without defects and fit for purpose. Our tests can be performed as standalone evaluations or as part of larger metallurgical testing projects, giving you the flexibility to address your exact testing needs.

- Customized etching methods by material type

- Standalone or comprehensive testing packages

- Routine quality checks

Components and materials we test

Components and materials we test

Element's Macro Etching services cover a comprehensive range of metals and components including nickel-based alloys, titanium-based alloys, stainless steel, beryllium, and various aerospace and industrial components. We specialize in critical rotating parts, fan blades, compressor blades, compressor vanes, discs, housings, forgings, and engine components – helping you verify material quality from routine quality checks to complex failure investigations.

- Nickel and titanium-based alloys

- Stainless steel components

- Beryllium materials

- Critical rotating parts

- Fan and compressor blades

- Engine components and cases

- Forgings and castings

Cutting-edge equipment we use

Cutting-edge equipment we use

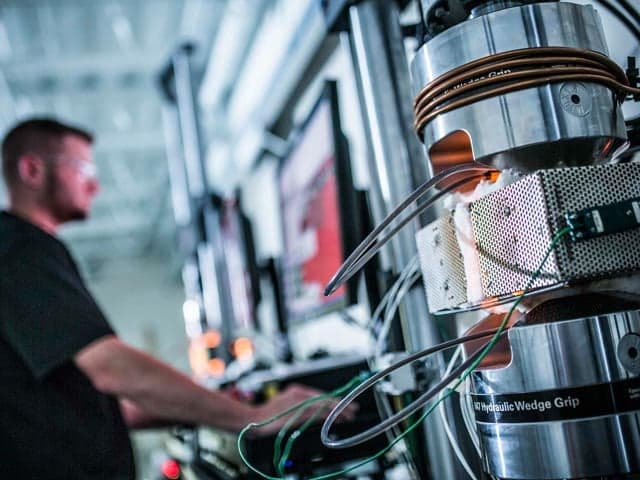

Our laboratories feature state-of-the-art equipment and specialized chemical processing systems designed to handle your most demanding inspection requirements. With complete in-house capabilities including equipment, chemicals, procedures, qualified personnel, waste treatment, and environmental permits, we deliver consistent, high-quality results while maintaining compliance with environmental regulations through our comprehensive waste management protocols.

- Advanced material testing equipment

- Specialized chemical etching solutions

- Low-magnification observation tools

- Environmental control technologies

- Complete testing laboratories

- State-of-the-art analysis systems

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing hubs worldwide, giving you global access to our expertise. Visit our Locations Page to explore our lab network.

Standards we test to and components we test

- EIM Code 2 Method E, F, G, and X

- EIM Code 7 (chem milling)

- MTV 238, LHP6017, EMS52390, RPS674

- DMC 0320, DMC 0324, DMC 0330

- DMP12-107, DMP13-049 (Ti pickling)

- CP3605, AMS 2643

- P4TF2, P4TF3, P4TF4, P4TF8 (swab etch)

- C5049 (Ti cleaning), PWA 116 (Ti cleaning)

- RRP 51001

- ASTM A561, ASTM A604, ASTM E1181, ASTM E112

- ASTM E340, ASTM E381, ASTM E407, ASTM E930

- BS EN 10328:2005, BS EN ISO 2639:2002, BS EN ISO 643:2012

- EN 3684

- ISO 643, ISO 4967:2013

- SAE ARP 1341B

Metals

- Nickel-based alloys

- Titanium-based alloys

- Stainless steel

- Beryllium

Critical components

- Critical rotating parts

- Fan blades

- Compressor blades

- Compressor vanes

- Fan cases

- Discs and disks

- Housings

- Sonic shape forgings

- Splines

- Shafts

- Hubs

- Engine cases

- Segments

- Spacers

- Flanges

- Links

- Rings

- Castings

Your Challenges, Our Solutions

Catching potential failures early enough

Managing complex standards compliance processes

Testing expertise on demand

Material integrity verified

Why Choose Element

Global macro etching capabilities

Materials testing expertise

Flexible testing approaches

State-of-the-art facilities

Frequently asked questions

What types of defects can Macro Etching detect?

Macro Etching effectively detects a wide range of material characteristics including banding, surface discontinuities, fractures and defects, grain size and grain boundaries (when grains are large enough to be visible), corrosion, macrostructure issues, overheat conditions, white spots or "freckles" in nickel alloys, gross material segregations in titanium, and forging defects - all visible without microscopes or with very low magnification.

Do I need Macro Etching testing?

Our laboratories can perform many reliable metallurgical testing methods, each with distinct advantages. Our experts work with you to determine if macro etching is the best option for your specific material evaluation needs, considering whether you require cleaning, inspection, or both. We ensure you get the most appropriate testing for your quality verification or failure investigation requirements, and can provide an estimate of turnaround time and pricing based on your specific project needs.

Material Expertise

Our highly trained metallurgists bring specialized knowledge across diverse material types, helping you understand your materials more deeply and get the most out of your products. With Element experts actively serving on professional and standards committees including ASM and ASTM, you benefit from testing partners who are consistently at the forefront of new testing techniques and material innovations.

- Experienced metallurgical analysis

- Cross-material testing expertise

- Deep understanding of material properties

- Industry committee participation

- Advanced testing methodologies

- Comprehensive materials knowledge

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Chemical Etching Services

Element’s chemical etching services detect hidden defects, refine material surfaces, and prepare samples for advanced testing. Trusted for precise, non-destructive analysis - save time and cost by uncovering imperfections before NDT or mechanical testing.

Nital Etch Inspection Services

Element's Nital Etch inspection identifies overheating and surface variations in machined parts. Our certified, in-house process safeguards material integrity with industry-approved, non-destructive testing methods.

Aluminium Etching and Cleaning

Element provides high-quality aluminium etching and cleaning, ensuring surface preparation, defect detection, and compliance with industry standards. Our in-house expertise supports aerospace and manufacturing applications.

Anodic Etching Inspection

Element's anodic etching inspection service identifies grain structure, inclusions, and defects in stainless steel and nickel alloys. A critical non-destructive testing method for aerospace and industrial applications.

Blue Etch Anodize (BEA) Inspection

Element's Blue Etch Anodize (BEA) inspection detects surface defects in titanium components, helping aerospace and power generation industries maintain compliance and prevent failures with precision non-destructive testing.

Pre-penetrant Etch

Pre-penetrant etch removes smeared material for precise FPI inspection. Element provides industry-certified services, ensuring optimal surface preparation for accurate testing results.