Radiographic Testing (RT) and Inspection Services

Detect hidden defects and verify product integrity without damaging your components. With radiographic testing, you'll identify critical flaws before they impact performance, meet stringent compliance requirements, and maintain comprehensive documentation for quality assurance—all while keeping your projects on schedule and reducing environmental impact.

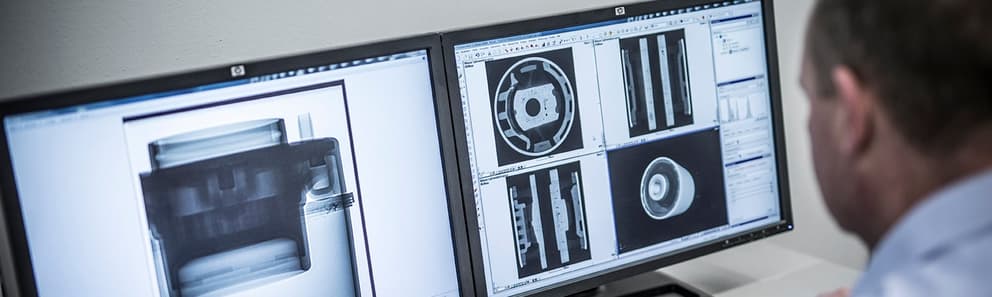

What is Radiographic Testing (RT) and Inspection at Element?

Radiographic Testing (RT) is a powerful non-destructive testing method that uses x-rays or gamma rays to identify internal flaws in materials and components without causing damage, including porosity, inclusions, and cracks that could impact performance. At Element, we provide comprehensive radiographic inspection services across multiple methodologies; from traditional film to advanced digital techniques, to detect defects such as porosity, inclusions, and cracks that might otherwise compromise your products' integrity and performance.

What Can Element Offer You For Radiographic Testing (RT) and Inspection Services?

Key Tests Offered

Key Tests Offered

Our radiographic services detect crucial defects that could compromise your products, providing certainty when it matters most:

- Volumetric flaw detection revealing internal discontinuities

- Porosity identification and characterization

- Inclusion detection across metals and composites

- Crack verification in stressed components

- Internal geometry assessment of assembled products

- Weld quality verification to meet industry standards

- Casting integrity validation for critical applications

Components And Products We Test

Components And Products We Test

From critical aerospace components to energy sector infrastructure, we specialize in radiographic examination of complex assemblies where quality is non-negotiable. Our capabilities extend across industries with expertise in:

- Aircraft structures

- Aerospace turbine components

- Energy Sector components including boilers and pressure vessels

- Castings in various metals (steel, aluminum, titanium, magnesium)

- Forgings and machined parts

- Structural steel elements

- Valves and industrial components

- Welds and weld overlays for critical applications

Methods And Solutions Offered

Methods And Solutions Offered

We provide a complete spectrum of radiographic inspection capabilities, offering both conventional and advanced methods to match your specific material and product requirements:

- Conventional Film Radiography delivering high-resolution documentation

- Close Proximity Radiography (CPR/SCAR) eliminating the need for area evacuation

- Computed Radiography (CR) producing digital images without chemical processing, providing faster processing and reducing environmental impact

- Digital Radiography (DR) with real-time results and 70-90% time savings

- Linear Accelerator Testing (LINAC) for rapid penetration of thick/dense materials

- Computed Tomography (CT) creating detailed 3D visualizations of internal structures

- Portable options for on-site field inspections when components can't be moved

The digital advantage

Modernize your inspection process with our digital radiography capabilities. These advanced methods deliver significantly shorter exposure times, eliminate film and chemical costs, reduce environmental impact, and enable electronic sharing of results with your team. Digital radiography provides excellent image quality with a high probability of detection, significantly reducing processing time by up to 70-90%, while also offering attractive pricing through operational efficiencies and resource conservation.

Our global experts are Level 3 qualified and on hand, ready to recommend the most suitable testing methods for your upcoming projects.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Access the latest in radiographic technology through our state-of-the-art equipment:

- Digital Detector Arrays (DDA) for instant image processing and review

- High-resolution reusable imaging plates reducing waste and costs

- 6MeV Linear Accelerators providing high-energy penetration of thick steel

- Advanced CT systems with automated detector motion for precise 3D rendering

- Specialized x-ray tubes and cabinets optimized for various materials

- Film digitization capabilities bridging traditional and digital methodologies

- Secure digital storage systems protecting your inspection records

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and products we test

Aerospace Material Specifications

- AMS 2175

- AMS 2635

American Society of Mechanical Engineers (ASME)

- ANSI/ASME B31.1

- ANSI/ASME B31.3

- ASME Section IX

- ASME Section V Article 2

- ASME B16.34

American Petroleum Institute (API)

- API STD 6A

- API STD 1104

ASTM International

- ASTM D2950

- ASTM E94

- ASTM E192

- ASTM E1030

- ASTM E1032

- ASTM E1472

- ASTM E1742

American Welding Society (AWS)

- AWS D1.1

- AWS D1.2

- AWS D1.3

- AWS D1.4

- AWS D1.5

- AWS D17.1

British / European Standards Institution

- EN 1435

- EN ISO 17636-1

- EN ISO 17636-2

Military Standards

- MIL-STD-139

- MIL-STD-202

- MIL-STD-271

- MIL-STD-453

- MIL-STD-750

- MIL-STD-2175

DEF-STAN 02-729 Part 1

Naval Sea Systems Command (NAVSEA)

- NAVSEA T9074-AS-GIB-010/271

NORSOK Standards

- NORSOK M-630

- NORSOK M-650

ASTM E1030

- Standard Test Method for Radiographic Examination of Metallic Castings

ASTM E1032

- Standard Test Method for Radiographic Examination of Weldments

ASTM E1165

- Standard Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Measuring

ASTM E1316

- Standard Terminology for Nondestructive Examinations

ASTM E1742

- Standard Practice for Radiographic Examination

ASTM E1817

- Standard Practice for Controlling Quality of Radiological Examination by Using Representative Quality Indicators (RQIs)

ASTM E2002

- Standard Practice for Determining Total Image Unsharpness in Radiology

ASTM E2033

- Standard Practice for Computed Radiology

ASTM E2104

- Standard Practice for Radiographic Examination of Advanced Aero and Turbine Materials and Components

ASTM E2339

- Standard Practice for Digital Imaging and Communication in Nondestructive Evaluation (DICONDE)

ASTM E2422

- Standard Digital Reference Images for Inspection of Aluminum Castings

ASTM E2869

- Standard Digital Reference Images for Magnesium Castings

ASTM E2445

- Standard Practice for Performance Evaluation and Long-Term Stability of Computed Radiography Systems

ASTM E2660

- Standard Digital Reference Images for Investment Steel Castings for Aerospace Applications

ASTM E2669

- Standard Digital Reference Images for Titanium Castings

ASTM E2738

- Standard Practice for Digital Imaging and Communication Nondestructive Evaluation (DICONDE) for Computed Radiography (CR) Test Methods

QCM 9.1.18

- Procedure for Computed Radiography Inspection, PCC Structurals Inc.

RRP-58009

- Digital Radiographic Inspection, Rolls-Royce

RRP-58000

- Technical Control of Non-destructive Testing, Rolls-Royce

Pr-5200

- Radiology Inspection on Film, Safran

DMC 0050

- Inspection Instructions – X-Ray Inspection, Safran

Pr 5200

- Products for Radiology on Film, Safran

P3TF5

- Radiographic Inspection, GE

P3TF38

- Non-Film Radiological Inspection, GE

DRM-Master

- Digital Radiography Method, Pratt & Whitney

J-ISAJT-A003

- Radiographic Inspection, IHI

J-ISAJT-A006

- Non-Film Radiographic Inspection, IHI

HGS1005

- Digital Radiographic Inspection, Honeywell

- Aircraft Components

- Aircraft Structures

- Aerospace Turbine Components

- Advanced Aero Materials

- Energy Sector Components

- Boilers

- Pressure Vessels

- Valves and Components

- Structural Steel

- Metal Products

- Castings

- Steel

- Aluminum

- Titanium

- Magnesium

- Forgings

- Welds and Weld Overlays

- Machined Parts

Your Challenges, Our Solutions

Undetected Flaws Risking Safety

Complex Compliance Requirements

Inspection Delays Impacting Your Timelines

High Environmental Impact of Testing

Why Choose Element

Comprehensive radiographic solutions

Certified inspection specialists

Advanced digital capabilities

No-evacuation testing options

6 advanced radiographic testing methods

70-90% faster inspection with digital methods

190+ years of materials testing certainty

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

What is the difference between Computed Radiography (CR) and Digital Radiography (DR)?

Computed Radiography uses imaging plates that must be scanned after exposure, while Digital Radiography employs digital detector arrays (flat panel detectors) that display images immediately. DR offers 70-90% shorter exposure times and faster image capture speed, though CR remains a simpler and still effective digital solution for many applications.

What are the different test methods that you offer for radiographic testing?

Element’s digital radiographic test methods capture inclusions digitally using Digital Detector Arrays (DDA) and reusable imaging plates, instead of traditional methods using x-ray film. We use three main test methods for digital radiographic testing:

- Computed radiography (CR) is the simplest digital radiography method. The item is exposed by x-ray tubes in cabinets, the imaging plate (IP) captures the image, and the IP is digitally scanned for display onto a high-resolution viewing monitor.

- Digital radiography uses a digital detector array, also known as a flat panel detector, with specialized x-ray tubes. The detector is rigid, exposure times are 70-90% shorter, and labor costs are significantly reduced. The image capture speed for DR is faster than alternate methods.

- Computed tomography is an extension of DDA technology. It uses an automated detector motion to gather thousands of digital images at various angles to create a 3D image.

What is Close Proximity Radiography (CPR) and when should it be used?

Also known as Small Controlled Area Radiography (SCAR), CPR is a unique industrial radiography process that doesn't require evacuation of personnel during testing. It can produce both film and digital imaging results, making it ideal for situations where maintaining workflow in adjacent areas is critical during inspection procedures.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Ultrasonic Testing (UT) Services

Detect hidden defects with Element's ultrasonic testing services. Our expert teams provide both contact and immersion UT inspection to verify component integrity, meet standards, and prevent failures.

Liquid Penetrant Inspection (LPI)

Element's liquid penetrant inspection identifies surface flaws with precision. Our experts provide reliable, cost-effective testing for aerospace, nuclear, and commercial applications, delivering accurate results to support compliance and quality assurance.

Magnetic Particle Inspection (MPI) Services

Element's experts carry out non-destructive magnetic particle inspection tests to check for surface and near-surface discontinuities in ferrous metals.

Linear Accelerator Testing (LINAC)

Element's Linear Accelerator Testing delivers fast, high-energy radiographic inspection for thick steel castings. Detect defects efficiently with non-destructive testing for aerospace, defense, and energy applications.