Industrial Computed Tomography

Gain unprecedented insight into your components through non-destructive, contactless 360° CT scanning. Our advanced technology delivers precise 3D visualization at micrometer resolution, enabling comprehensive internal and external component analysis without compromising sample integrity. Unlock detailed insights for quality control, reverse engineering, and advanced manufacturing optimization.

What is Industrial Computed Tomography at Element?

Industrial Computed Tomography is a non-destructive testing method that creates precise 3D visualizations of internal structures. At Element, we utilize CT scanning systems that work by directing X-rays through components, which are absorbed to varying degrees depending on material density and thickness. These absorbed X-rays generate detailed grayscale images as residual radiation hits a detector.

By rotating test objects a full 360°, our systems produce hundreds of individual radiographic images. Advanced computational algorithms then reconstruct these images into comprehensive 3D models, enabling detailed analysis using specialized software or direct integration with CAD programs.

What Can Element Offer You For Industrial Computed Tomography?

Key Tests Offered

Key Tests Offered

We provide comprehensive component analysis for production control and quality assurance, delivering precise measurements and detailed defect detection. Our advanced testing capabilities support your manufacturing excellence through:

- Defect analysis (pores, voids, inclusions)

- Wall thickness measurement

- Surface determination

- Target/actual comparisons

- Assembly and joining inspection

- Leak and corrosion visualization

Components We Test

Components We Test

Our ICT capabilities examine plastics, composites, light metals, and complex assemblies for comprehensive quality control and development. We specialize in analyzing internal structures of manufactured components, from individual parts to complete assemblies, delivering detailed insights for production optimization and quality assurance. Our expertise spans:

- Electronic assemblies and components

- Weld seams and joining points

- Prototypes and production parts

- Encapsulated electronic assemblies

- Complex mechanical assemblies

Methods And Solutions Offered

Methods And Solutions Offered

Our CT scanning creates detailed 3D models through 360° rotation imaging, producing hundreds of high-resolution radiographic images. These are reconstructed into comprehensive 3D models compatible with CAD software, enabling precise analysis of internal and external features.

The high-resolution and three-dimensional imaging of objects in industrial computed tomography is useful for a variety of applications and uses. These include:

- Defect analysis

- 3D Measurement and metrology

- Assembly and joining inspection

- Reverse engineering

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

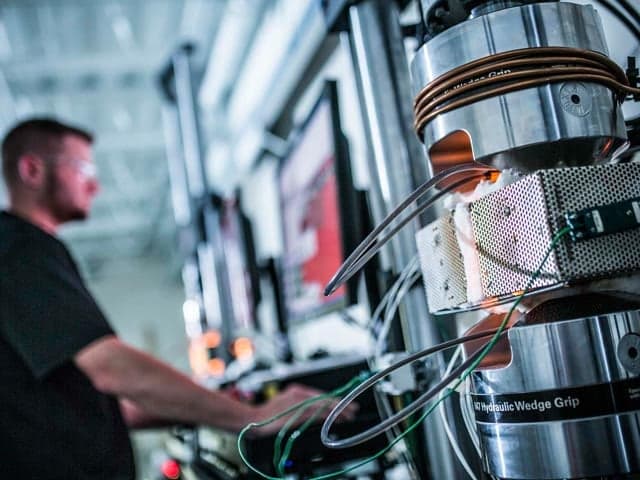

We utilize advanced CT scanning systems with up to 450 kV power for high-precision examination of components and electronic assemblies. Our technology enables detailed visualization at micrometer resolution, supported by sophisticated analysis software for comprehensive component evaluation and measurement capabilities.

Which Labs Offer This Service

Which Labs Offer This Service

Our global laboratory network, anchored by our specialized facility in Aalen, Germany, delivers industrial CT scanning services worldwide. Each location maintains modern scanning systems and expert staff for consistent, high-quality results delivered on time and on budget to meet your specific requirements.

Materials we test

Industrial CT scanning is suitable for almost all materials and is particularly good for:

- Plastics

- Carbon fiber reinforced plastics (CFRP)

- Glass fiber reinforced plastics (GFRP)

- Aluminum

- Magnesium

It may be that other materials can be better inspected for flaws using other non-destructive testing methods, such as:

Your Challenges, Our Solutions

Precision internal inspection requirements

Quality control issues adding cost

Assembly verification without disruption

Accurately modeling critical components

Why Choose Element

Global accessibility

Cutting-edge technology

Comprehensive analysis

Customer-focused solutions

450 kV

360°

3D

4+

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

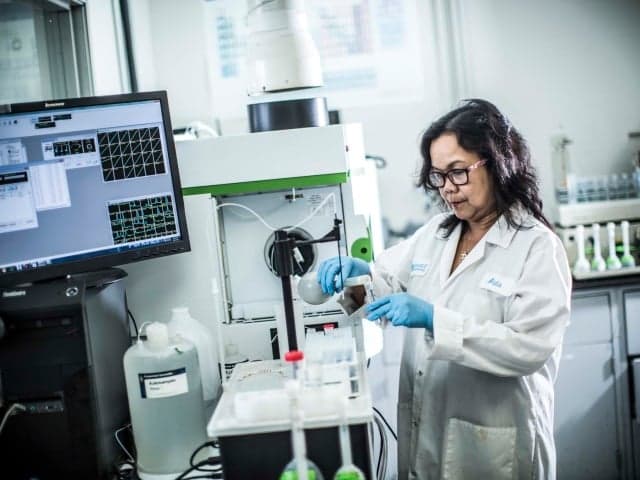

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.