Orthopedic Device Testing Services

Your orthopedic implants face rigorous regulatory scrutiny and complex testing requirements. Element's comprehensive Orthopedic Device Testing services help you navigate these challenges with confidence. We provide specialized testing solutions that ensure your devices meet safety and performance standards, reducing development time and helping you bring innovative solutions to patients faster.

What is orthopedic device testing at Element?

Orthopedic Device Testing evaluates the safety and performance of medical implants that restore skeletal function. These devices experience multiple forces inside the body, including torsion and wear, making comprehensive testing vital for patient safety. At Element, we provide specialized testing services that simulate real-world conditions to verify your devices meet required performance standards throughout their lifecycle.

What can element offer you for Orthopedic Device Testing services

Products We Test

Products We Test

Element delivers comprehensive testing across your full range of orthopedic implants. From major systems like hip and knee implants to specialized components such as dental implants and fixation devices, our laboratories accommodate diverse configurations of orthopedic devices. We test various materials and designs, helping you verify performance across your entire product portfolio.

Key Tests Offered

Key Tests Offered

Our specialized orthopedic testing capabilities include both long-term and static evaluations. We provide wear testing to simulate years of use, comprehensive fatigue testing under various loading conditions, and static testing to evaluate structural integrity. Additional services include destructive testing of bone plates and screws, in-situ environment testing, and custom test procedure development tailored to your specific requirements.

Methods And Solutions Offered

Methods And Solutions Offered

Element's orthopedic testing solutions support your device through every development stage. We assist with procedure review and development for early-stage designs, conduct predicate testing for regulatory comparisons, and provide comprehensive R&D support. Our testing programs accommodate unique requirements including in-situ environments, biological tissue testing, and custom test procedures, giving you flexibility to address specific design challenges.

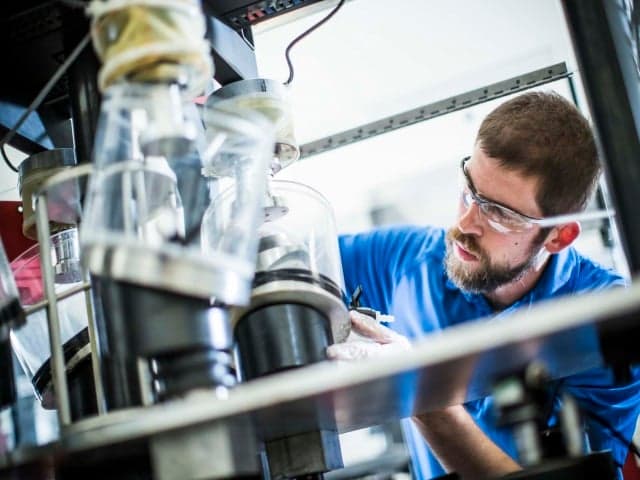

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our laboratories feature specialized equipment for conducting various orthopedic device tests, including mechanical testing systems capable of simulating wear, fatigue, and static loading scenarios. We maintain advanced testing capabilities that replicate real-world conditions your implants will experience, ensuring reliable performance data that accurately predicts in-body function.

Which Labs Offer This Service

Which Labs Offer This Service

Element's orthopedic device testing services are available through our network of specialized medical device laboratories, with our Minnetonka, MN and Cincinnati, OH centers of excellence for orthopedic testing.

Standards we test to and products we test

Our orthopedic device testing follows rigorous industry standards, including:

Hip Implant Standards

- ISO 7206: Implants for surgery - Partial and total hip joint prostheses

- ASTM F1223: Standard Test Method for Determination of Total Hip Replacement Stem Distal Centralization

Knee Implant Standards

- ASTM F1800: Standard Test Method for Cyclic Fatigue Testing of Metal Tibial Tray Components

- ISO 14243-1/3: Implants for surgery - Wear of total knee-joint prostheses

Spinal Implant Standards

- ASTM F1717: Standard Test Methods for Spinal Implant Constructs in a Vertebrectomy Model

- ASTM F1798: Standard Test Method for Evaluating Interconnection Mechanisms of Spinal Implants

- ASTM F1854: Standard Test Method for Stereotactic Accuracy of Navigation Systems

Additional Standards

- ISO 14801: Dentistry - Implants - Dynamic fatigue test for endosseous dental implants

- ASTM F2665: Standard Specification for Total Ankle Replacement Prosthesis

For a complete list of all standards for specific orthopedic device types, please visit our dedicated testing pages for each device category.

- Hip implant systems (modular and non-modular)

- Knee prostheses and components

- Spinal implants (fusion and non-fusion devices)

- Bone screws, plates and fixation devices

- Extremity and shoulder replacement implants

- Dental implants

- Porous coatings

- Biological tissues

- Custom orthopedic designs

Your Challenges, Our Solutions

Complex Regulations

Innovative Design Challenges

Time-to-Market Pressure

Predicate Comparison Needs

Why Choose Element

Industry Leadership

Comprehensive Solutions

Custom Testing Capabilities

Regulatory Support

Related services

Bone Plate, Bone Screw, and Fixation Device Testing

Our testing service verifies the mechanical integrity of bone plates, screws, and fixation devices through ASTM-standard fatigue, bending, and torsion evaluations, providing critical data for regulatory compliance and trauma reliability.

Foot, Ankle, and Shoulder Replacement Implant Testing

Element offers expert foot, ankle, and shoulder implant testing, covering fatigue, wear, and constraint analysis to support orthopedic device development and regulatory submissions.

ISO 14801: Dental Implant Testing

Element provides ISO 14801 dental implant fatigue testing to support regulatory approval. Our experts deliver precise data on implant durability, lifecycle, and performance for safe market entry.

Hip Joint Prosthesis Testing

Element provides ISO 7206-compliant hip joint prosthesis testing, assessing endurance, fatigue, and compression to support safe, high-performing medical devices worldwide.

Knee Implant Testing

Element offers expert knee implant testing, including fatigue, wear, and constraint analysis, to support device design, feasibility studies, and regulatory compliance.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

Spinal Implants Testing Services

Element's trusted medical device testing covers fusion and non-fusion spinal devices, as well as predicate components, to ensure their durability and lifespan in use.

Cleanliness and Microbiological Testing

Element's Cleanliness and Microbiological Testing service validates cleaning processes, evaluates microbial loads, and performs bioburden, endotoxin, and cytotoxicity tests to reduce contamination risks and support device performance and patient safety.

Frequently asked questions

What types of orthopedic device testing does Element offer?

Element provides a comprehensive range of orthopedic device testing including wear testing, fatigue testing, static testing, destructive testing, and custom test procedures. Our services cover hip implants, knee prostheses, spinal devices, bone screws and plates, extremity replacements, and dental implants.

How does Element support the full development cycle for orthopedic devices?

We offer complete support from prototype to commercialization, including design and prototype phase testing, design verification and validation, regulatory submission support, and post-launch testing. This comprehensive approach ensures consistent quality throughout your product's lifecycle.