Wear Testing of Medical Devices

Ensure your medical device meets rigorous performance standards with our comprehensive wear testing. We manage your testing program, simulating real-world body conditions to validate implant durability and support regulatory submissions. Our advanced wear testing for hip, knee, and spinal implants provides the reliable data and expertise you need to confidently bring innovative devices to market

What is Wear What is wear testing of medical devices at Element?

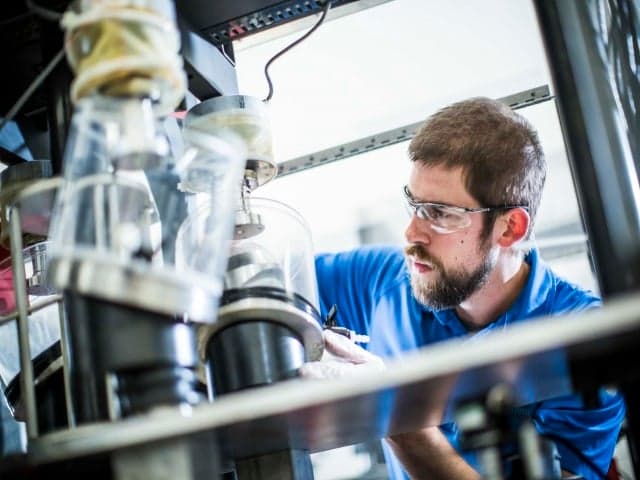

Medical device wear testing characterizes the tribological properties of implants and prosthetics by precisely simulating human body kinematics and kinetics. Here at Element, we provide comprehensive in-house testing that meticulously evaluates device performance, material interactions, and wear characteristics through advanced simulation techniques.

What can element offer you for Wear Testing of Medical Devices service

Components And Products We Test

Components And Products We Test

We test a comprehensive range of medical device components including hip implants, knee replacements, spinal devices, and complex material interactions. Our testing covers femoral heads, acetabular liners, tibial inserts, and various material couples used in medical device manufacturing.

Key Tests Offered

Key Tests Offered

- Knee wear testing

- Spine wear testing

- Orbital hip testing

And within those, we conduct:

- Tribological property characterization

- Wear rate measurement

- Mass loss analysis

- Particulate characterization

- Side-by-side predicate device comparison

Methods And Solutions Offered

Methods And Solutions Offered

- ISO 14242-3 compliant testing

- Force and displacement controlled testing

- Complex motion simulation

- Environmental chamber testing

- Comprehensive reporting for regulatory submissions

Orbital Hip Wear Testing:

We conduct hip implant wear testing in compliance with ISO 14242-3, simulating walking kinematics with our advanced hip wear simulators. These simulators provide the complex motions needed for accurate wear testing, ensuring the performance of your implants in real-life scenarios. Hip implants are submerged in bovine solution in an environmental chamber, following ISO 14242-3. The implants undergo repeated motion cycles at 1Hz up to 5,000,000 cycles, with mass loss measurements taken periodically (typically 7 times during the test). All test stations are linked to ensure uniform axial force and displacement. The implants undergo repeated motion cycles, with mass loss measurements taken periodically (typically 7 times during the test). After testing, particulate from the femoral head/acetabular liner interaction is analyzed using SEM/EDS.

Knee Wear Testing:

We offer both force-controlled (ISO 14243-1) and displacement-controlled (ISO 14243-3) wear testing for knee replacement devices, simulating real-life gait kinematics. Our equipment measures wear between the femoral component and tibial insert. We simulate complex knee motions using force-controlled or displacement-controlled methods, including coupled axial force (Fz), anterior/posterior force (Fx), flexion/extension (My), and tibial rotation (Mz) to accurately simulate the complex, simultaneous motions of the human knee. Periodic mass loss measurements are taken using the stringent clean, dry, and weigh process per ISO 14243. The post-test particulate is also evaluated using scanning electron microscopy (SEM) after the conclusion of testing.

Spine Wear Testing

Element provides spine wear testing per ASTM F2423 and ISO 18192, using our advanced MTS Bionix® Spine Wear Simulator to replicate spinal implant conditions. Our 6-station simulator with load/soak control offers 6 degrees of freedom to meet ASTM F2423 and ISO 18192 standards. After testing, wear surfaces and particles are evaluated in our metallurgical lab using SEM, EDS, and stereoscopic equipment.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

- 6-station MTS Bionix® Spine Wear Simulator

- Proprietary hip wear simulators

- 6 test stations with load/soak controls

- Scanning Electron Microscopy (SEM)

- Energy Dispersive Spectroscopy (EDS)

For orbital hip wear testing, our custom hip wear simulators feature 6 test stations with precise load/soak controls. Each station simulates walking movements with a 23° bi-axial rocking motion, replicating flexion/extension, abduction/adduction, and internal/external rotation.

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Comprehensive Support

Standards we test to and products we test

- Metallic Implant Materials

- Polymer Components

- Ceramic Interfaces

- Composite Materials

- Bearing Surface Materials

Your Challenges, Our Solutions

Ensuring Long-Term Device Performance

Meeting Regulatory Requirements

Comparing Device Generations

Characterizing Material Interactions

Why Choose Element

Global Testing Network

Comprehensive In-House Capabilities

Cutting-Edge Simulation Technology

Regulatory Submission Support

8,500+engaged experts

6station testing capability

4-6month typical testing duration

Related services

Electronic Product Certification and Approvals Services

Accelerate your electronic product certification with Element's ISO 17065-accredited services. Access 167 markets through one trusted partner. Expert testing & compliance support.

Medical Device Testing Services

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier across feasibility, R&D and prototype trials, through product development, regulatory validation and production quality control.

Pin on Disk Wear Testing

Pin on disk wear testing evaluates material wear performance under controlled conditions. Ideal for regulatory requirements and material comparison, Element's advanced methods and expertise deliver reliable insights.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Accelerated Aging Shelf Life Testing Services

Accelerated aging and shelf life testing predict product durability, reduce risk, and meet industry standards, providing data-driven insights for medical, packaging, and food sectors.

Frequently asked questions

When is wear testing required?

The FDA and other regulatory bodies will often request mechanical wear testing when the device is introducing a new material couple or new material interactions that have not been adequately characterized through mechanical testing. Wear testing is also critical for comparing the wear properties of new devices to a previous-generation device