Low Lubricity Aircraft Fuel Testing Services

Your aircraft components demand peak performance under extreme conditions. Our single-source low lubricity aircraft fuel testing helps predict component lifespan, reduce maintenance costs, and validate product safety through rigorous ASTM D5001 BOCLE evaluation. With custom-built systems capable of running thousands of test hours, we deliver reliable data about your products' performance in worst-case scenarios.

What is Low Lubricity Aircraft Fuel Testing at Element?

Low lubricity testing examines how aging and temperature-stressed aircraft fuels affect mechanical wear in moving parts. This testing focuses on the relationship between the age and temperature of fluid, and the mechanical wear of products in operation. At Element, we simulate worst-case operating conditions using specially conditioned fluids to analyze component durability and predict maintenance requirements, helping you make informed decisions about product lifecycle.

What Can Element Offer You For Low Lubricity Aircraft Fuel Testing?

Key Tests Offered

Key Tests Offered

Element deliver complete ASTM D5001 compliance testing to support Low Lubricity Aircraft Fuel Testing, using Ball on Cylinder Lubricity Evaluator (BOCLE) technology. Our testing programs include operational cycling, performance monitoring, and detailed component breakdown analysis. We conduct comprehensive wear pattern analysis and performance degradation studies under various operational conditions, providing reliable predictions about how well your products will survive under the most taxing conditions.

- ASTM D5001 standardized BOCLE testing

- Operational cycling with specially conditioned fluids

- Performance monitoring throughout testing lifecycle

- Detailed component breakdown and failure analysis

- Wear pattern identification and assessment

- Degradation progression monitoring

Components & Products We Test

Components & Products We Test

Your aviation components undergo comprehensive testing in our custom-built facilities. We specialize in testing engine parts, fuel system components, and critical moving components that require precise lubricity evaluation. Our expertise extends to all types of aircraft mechanical systems where fuel interaction affects component performance and longevity. As lubricating fluids are cycled over time, they become less effective at reducing friction, and our testing identifies exactly how this impacts your specific components.

- Aircraft engine components including pumps and actuators

- Fuel system components such as valves and regulators

- Moving parts in aviation systems requiring lubrication

- Mechanical wear components in high-stress environments

- Operational fluid systems with extended service requirements

- High-temperature environment components

Methods And Solutions Offered

Methods And Solutions Offered

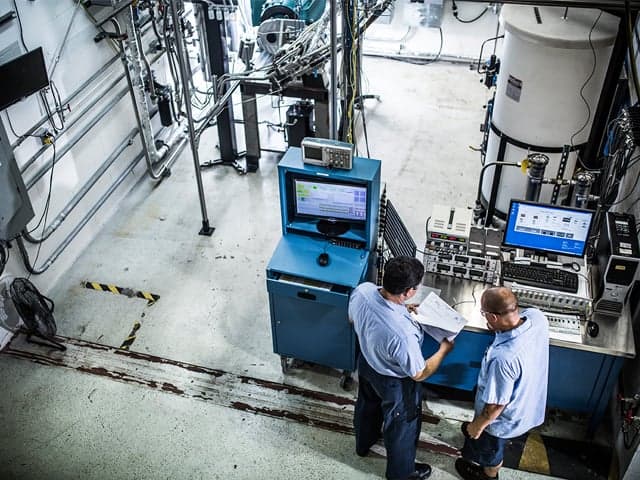

Your components receive thorough evaluation through custom-designed clay filtration systems that remove a variety of compounds from the test fluids. We employ controlled temperature environments and automated long-duration testing capabilities that can run for thousands of hours. Our sophisticated monitoring systems track performance metrics throughout the testing cycle, providing detailed insights into component behavior and identifying the most susceptible features before costly issues arise in real-world operations.

- Custom clay filtration systems for precise lubricity control

- Controlled high-temperature environments for accelerated testing

- Automated long-duration testing for thousands of operational hours

- Real-time performance monitoring and data collection

- Comprehensive breakdown analysis after testing completion

- Early identification of susceptible component features

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Our in-house built systems include advanced BOCLE technology for quantifying the lubricity value of test fluids, custom clay filters for precise lubricity control, and automated test stands capable of extreme temperature and power conditions. We utilize state-of-the-art monitoring equipment and custom-designed testing apparatus to ensure accurate and reliable results across all test parameters, even for the largest and most complex projects.

- Ball on Cylinder Lubricity Evaluator (BOCLE) systems

- Custom-designed clay filtration systems

- Automated test stands for extended duration testing

- High-temperature environmental simulation chambers

- Advanced performance monitoring equipment

- Specialized breakdown and analysis tools

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from Product Qualification Testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest Product Qualification Testing hub is on our Locations Page.

Standards we test to and components we test

- ASTM D5001 (Standard Test Method for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator)

- Custom client specifications and requirements

- Industry-specific aviation fuel standards

Aircraft components

- Aircraft engine components

- Pumps and actuators

- Valves and regulators

- Bearings and rotating assemblies

System components

- Fuel system components

- Hydraulic system elements

- Moving parts in aviation systems

- Control system mechanisms

Performance-critical components

- Mechanical wear components

- High-stress environment parts

- Operational fluid systems

- High-temperature environment components

Your Challenges, Our Solutions

From component wear to extended lifespan

Durability challenges solved through testing

Safety compliance made simple

High maintenance costs to optimized efficiency

Why Choose Element

Single-source testing excellence

Custom testing solutions

Extended duration testing

Advanced analysis capabilities

190+years

1,000s+hours

100%customer-built

8,500+engaged experts

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace

Element are the largest global independent provider of aerospace testing services with over 100 years of experience and world-class testing, qualification, calibration, and advisory services.

Avionics Systems Testing

Streamline your commercial, defense, and business/general avionics systems testing with Element's end-to-end aerospace testing solutions. Our expert engineers deliver critical EMC, environmental, and RF testing services across global labs. Learn More.

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.