Discrete Element Method (DEM) Services

Optimize processes, reduce costs, and enhance equipment performance with Element's Discrete Element Method (DEM) Services. Our GPU-powered simulations model millions of particles with exact real-world interactions, helping you predict granular flows, optimize powder processing, and refine machinery performance, across mining, agriculture and other key industries. Improve efficiency before implementation with our expert DEM analysis.

What is Discrete Element Method (DEM) at Element?

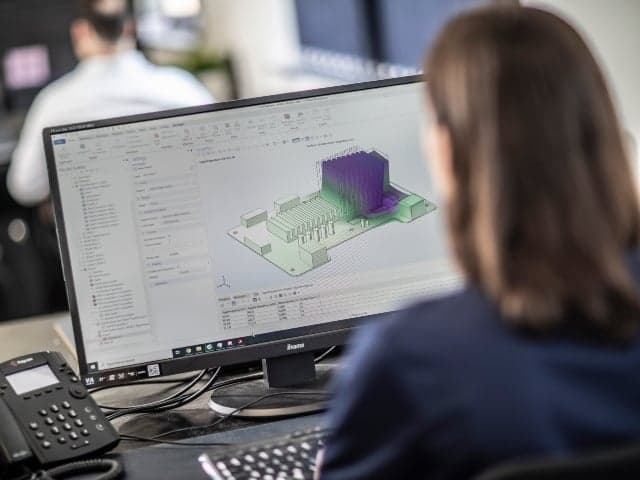

Element’s Discrete Element Method (DEM) services model the motion and interaction of millions of particles, Simulating real particle shapes and exact contact mechanics with complex geometries. Using advanced GPU-powered technology, we provide precise insights into granular flows, powder processing, soil mechanics, and equipment performance, helping industries optimize designs, predict wear, and improve efficiency.

What can Element offer you for Discrete Element Method (DEM)?

Key services offered

Key services offered

At Element, we provide standalone DEM analysis as well as integrated solutions with Computational Fluid Dynamics (CFD)and Finite Element Analysis (FEA). Our services deliver estimates on machine load, power consumption, and lifetime prediction, ensuring process optimization before full-scale implementation.

Components and materials we test

Components and materials we test

We specialize in analysing granular materials, powders, soil mechanics, agricultural products, and industrial particles. Our DEM models account for real particle shapes and interactions, allowing for precise flow behavior simulations in mining, pharmaceutical, agriculture, and manufacturing industries.

Cutting-edge equipment we use

Cutting-edge equipment we use

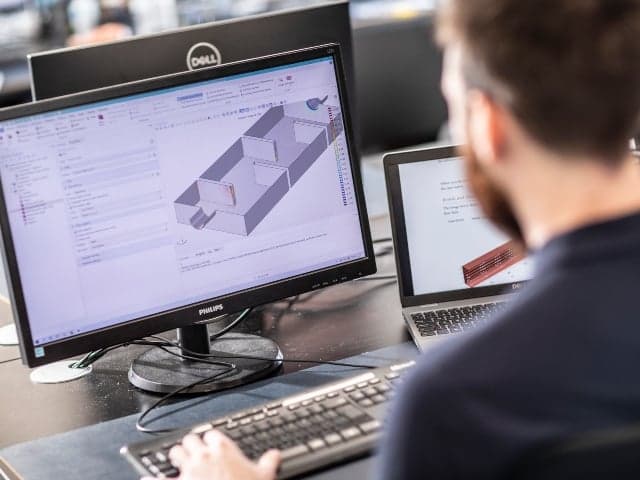

We leverage high-performance GPU computing enabling real-time modelling of millions of particles. Our advanced particle modelling software ensures accurate representation of granular flows and powder interactions. Additionally we integrate CFD & FEA tools to offer multi-physics simulations for in-depth analysis.

Which labs offer this service

Which labs offer this service

Our Bristol, Derby, and Houston digital engineering hubs house our state-of-the-art DEM capabilities, providing global access to Element’s advanced simulation and testing expertise. Explore our Locations Page to find the nearest facility for your testing needs.

Digital Innovation Leadership

Digital Innovation Leadership

As part of Element's expanding Digital Engineering division, our DEM services integrate with broader modeling, simulation, and data science capabilities. Our rapidly growing team operates at the forefront of digital transformation, delivering tailored, high-performance solutions to our clients worldwide.

Materials we test

- Granular materials

- Powder materials

- Soil materials

- Agricultural materials

- Industrial particles

- Mining materials

- Pharmaceutical materials

Your Challenges, Our Solutions

Computational Power Limitations

Process Optimization Hurdles

Equipment Lifecycle Uncertainty

Cost-Efficiency Demands

Element Experts at your service

Why Choose Element

Global Expert Network

Comprehensive Analysis Capability

Multi-Industry Experience

Advanced GPU-Powered Technology

Frequently asked questions

What is Discrete Element Method (DEM)?

DEM is a computational technique that simulates particle interactions, material behavior, and granular flows in real-world applications.

How does DEM integrate with CFD and FEA?

DEM can be combined with CFD for fluid-solid interactions and with FEA to assess mechanical stress and durability.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Digital Engineering Services

Element's Digital Engineering Services enhance reliability, reduce costs, and accelerate innovation through advanced simulations and data-driven insights. Our customized solutions streamline project lifecycles, ensuring optimized designs, regulatory compliance, and future-ready technology.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.