Flexural Testing for Composite Materials

Ensure reliable composite performance with fast, end-to-end flexural testing for composite materials. Our hands-on technical guidance analyzes tensile, compression, and shear behavior in three-point or four-point bend tests. We customize fixtures for your geometry, speeding data delivery and design validation. Partner with Element to reduce guesswork, optimize your product’s real-world durability, and meet compliance.

What is Flexural Testing for Composite Materials at Element?

Flexural testing evaluates a material’s ability to withstand bending forces by measuring strength and stiffness in a flexural mode. Because bending combines tensile, compression, and shear properties, a specimen fails once one of these stresses reaches its limit. At Element, we provide three-point and four-point bend testing for solid laminates and sandwich constructions, helping you predict real-world behavior under bending loads and identify which stress (tensile, compression, or shear) will dominate failure.

What Can Element Offer You for Flexural Testing for Composites?

Key Tests Offered

Key Tests Offered

We deliver both three-point and four-point bend testing to examine how your composite materials respond to bending forces. By controlling support distances and loading points, we adapt each fixture setup to accommodate different specimen sizes and thickness-to-length ratios—mirroring real-world applications. Our testing provides:

- Flexural strength measurement (material qualification)

- Flexural stiffness data (design validation)

- Failure mode insights (product improvement)

- Comparative testing for material selection/optimization

- Performance verification for quality assurance

Materials we test

Materials we test

From solid laminates to complex sandwich constructions, our flexural testing capabilities span the entire range of composite materials integral to aerospace, automotive, and renewable energy applications. Because bending is a mix of tensile, compression, and shear stresses, it’s crucial to evaluate each property under representative conditions. We also test unreinforced/reinforced plastics and electrical insulating materials, ensuring your designs meet performance and safety requirements.

- Solid laminates for aerospace and automotive structural parts

- Sandwich constructions for lightweight, high-strength applications

- Polymer matrix composites for high-performance demands

- Reinforced plastics for industrial/consumer products

- Electrical insulating materials for safety-critical uses

Methods And Solutions Offered

Methods And Solutions Offered

Our experts conduct testing to ASTM, ISO, and EN standards for both solid laminates and sandwich constructions. By adjusting support spans and loading noses, we replicate the conditions your product will face in service. Whether using three-point or four-point bend configurations, we precisely pinpoint how your materials will fail, guiding design optimizations before expensive production ramps up.

- Three-point bending (max stress at mid-span)

- Four-point bending (constant moment region, reduced shear influence)

- Customized fixture setups for non-standard geometries

- Controlled loading rates for time-dependent behaviors

- Detailed documentation for test repeatability

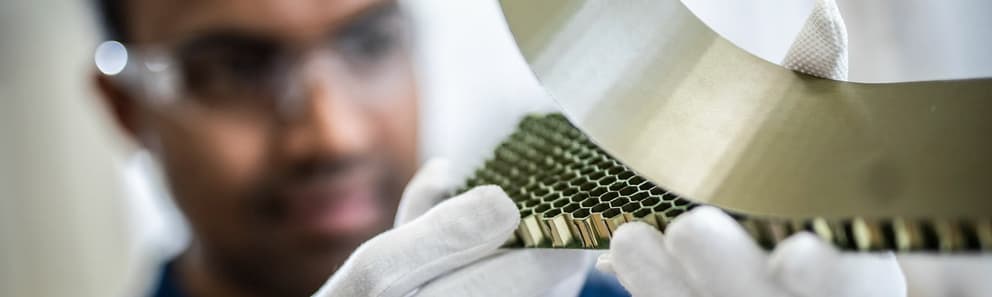

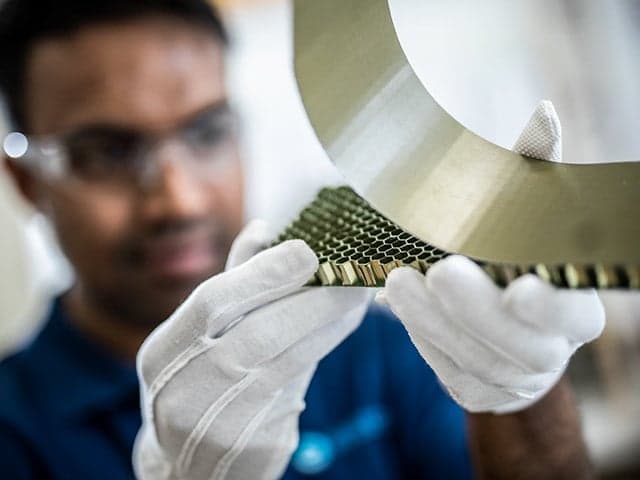

Fixture adaptability is vital. Our load frames and bend fixtures accommodate varied support distances to match unique sample geometries, ensuring that the bending data accurately reflects in-service conditions.

Comprehensive result interpretation

Beyond raw numbers, we interpret test data—identifying primary failure modes (tensile, compression, shear) and correlating them to your material’s design and use-case. This holistic approach transforms basic test outcomes into practical insights for enhancing product reliability, refining manufacturing processes, and ensuring your composites remain fit for purpose in demanding environments.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

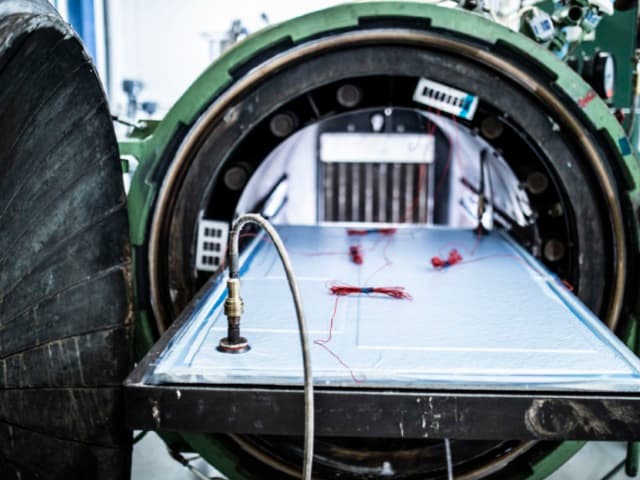

Element’s advanced testing equipment provides precise load application and high-resolution displacement measurement for accurate flexural property determination. Fixtures can be customized to suit various specimen dimensions, letting us replicate real assembly conditions. Our capabilities include:

- Precision load frames with accurate force measurement

- Adjustable support & loading configurations for different beam spans

- High-resolution displacement measurement systems

- Data acquisition for comprehensive analysis

- Environmental control if needed (temperature/humidity constraints)

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

Solid laminates

- ASTM D790

- ASTM D6272

- ASTM D7264

- EN 2562

- ISO 178

- ISO 14125

Sandwich constructions

- ASTM C393

- ASTM D7249

Element tests to EN, ISO, and ASTM standards for flexural testing of composite materials. Relevant ASTM standards include:

- ASTM D6272 – Four-Point Bending for Composites

- ASTM D7264 – Flexural Properties of Polymer Matrix Composites

- ASTM D790 – Flexural Properties of Unreinforced/Reinforced Plastics & Electrical Insulating Materials

- ASTM C393 – Flexural Properties of Sandwich Constructions

- ASTM D7249 – Long Beam Flexure Facing Properties for Sandwich Constructions

Solid laminates

- Polymer matrix composites

- Unreinforced plastics

- Reinforced plastics

- Electrical insulating materials

Sandwich constructions

- Sandwich panels with solid facings

- Composite sandwich constructions

Your Challenges, Our Solutions

Understanding complex material behavior

Design validation with actionable data

Standards compliance complexity

Overhead costs for specialized testing

Why Choose Element

Composite testing specialization

Customized test configurations

Comprehensive failure analysis

Standards-driven methodology

Frequently asked questions

How does flexural testing relate to real-world performance?

Flexural testing shows how composites bend under tension, compression, and shear. It identifies which stress limit triggers failure first for more accurate product design.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Curing Autoclave & Fabrication

Element provides composite curing autoclave and fabrication testing to verify durability, extend shelf life, and enhance mechanical properties, delivering fast, accurate results for high-performance applications.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.